FBGS DTG - Draw Tower Gratings

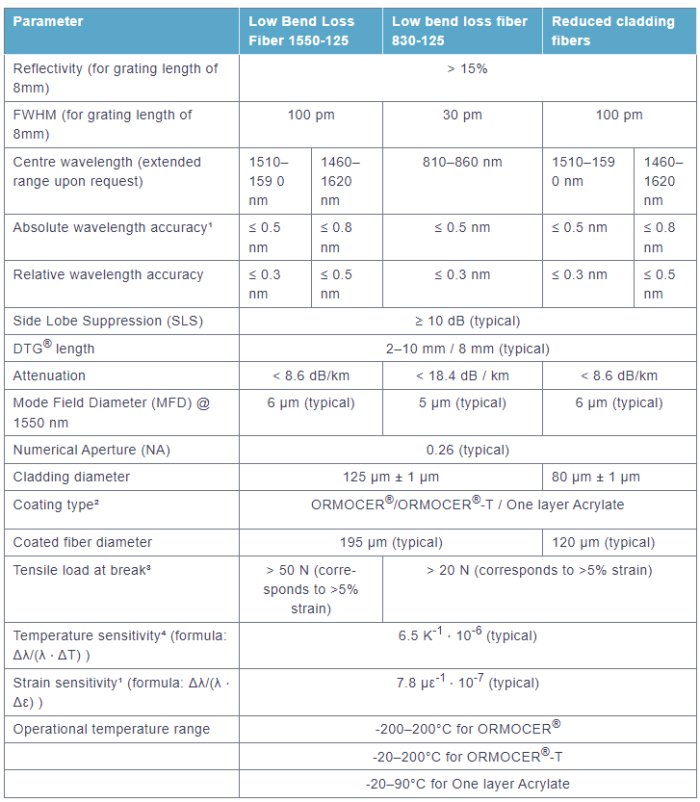

We offer three types of DTG® with unique characteristics compared to classically produced FBGs, such as extremely high breaking-strength, spliceless array configuration and uniform coating coverage. FBG parameters and coating material can be selected based on customer needs.

1550-125

Draw Tower Gratings (DTG®s) written in Low Bend Loss fiber LBL-1550-125 which has a cladding diameter of 125µm and is optimized for operation in the 1550nm wavelength window. The glass composition has been tuned such that the fiber maintains a good signal transmission under small bending diameters.

830-125

Draw Tower Gratings (DTG®s) written in Low Bend Loss fiber LBL-830-125 which has a cladding diameter of 125µm and is optimized for operation in the 830nm wavelength window. The glass composition has been tuned such that the fiber maintains a good signal transmission under small bending diameters.

Draw Tower Gratings (DTG®s) written into Low Bend Loss fiber LBL-1550-80 which has a cladding diameter of 80μm and is optimized for operation in the 1550nm wavelength window. The reduced cladding diameter offers several major advantages compared to standard 125µm fibers:

- Unobtrusiveness – particularly interesting for embedding applications including carbon composite structures and medical catheters.

- Increased sensitivity – less force is required to strain the fiber enhancing the performance of sensors based on force or acoustic sensing.

- Reduced bending radii – lower surface strain levels enabling more compact sensor designs.

- measured at room temperature

- ORMOCER® is mainly applied for strain measurements while ORMOCER®-T is recommended for temperature measurements.

- according to IEC-60793-1-31 using a constant displacement of 30 mm/minute

- measured between 0°C and 70°C

- Temperature range is dependent on exposure time.