- Home

- Companies

- Unicon Engineers

- Products

- Unicon - Dry Electrostatic Precipitator

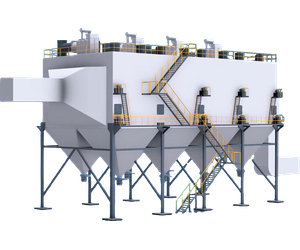

Unicon - Dry Electrostatic Precipitator

FromUnicon Engineers

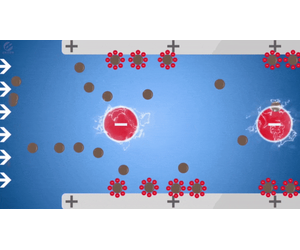

Designed to remove dry particulate matter, such as dust and ash, from industrial exhaust streams. They work by passing dirty gas between electrically charged plates and collecting the particles on those plates.

Most popular related searches

electrostatic precipitator

electrostatic precipitation

air pollution control system

particulate matter removal

pollution control system

air pollution control

dry electrostatic precipitator

dry electrostatic precipitation

particulate matter

cement industry

The Unicon Edge in Electrostatic Precipitation

- Ionization

- Migration & Collection

- Robust Construction

- Particle Discharge

- Customizable Designs

- Technical Support

Unicon's Electrostatic Precipitators excel with unique performance features

- Lower emission

- Energy Efficiency

- Ease of Maintenance

- Advanced Controls

- Parameter: Data

- Application: Power Plants - Boilers and Heaters, *Other Industries

- Capacity (Power Plant MW): 5 to 600

- Gas Temperatures (°C): 70 - 400

- Gas Flow Rate (m3/s): 5 - 1500

- ESP inlet dust loading (g/Nm3): 0.2 - 250 g/Nm3

- Guaranteed ESP outlet emission (mg/Nm3): 10 - 200 (suitable design for ESP as pre-collector), filterable PM only

- PM Collection Efficiency: Up to 99.95%

- Availability: Up to 98%

Other Industry —

- Cement: Kiln, Mills, Cooler;

- Iron & Steel: Sintering, Pelletization, Sponge Iron Kiln, Cast House, Stock House;

- Biomass fired boilers;

- Waste to Energy plants;

- Pulp & Paper: Recovery Boiler, Lime Kiln;

- Non-Ferrous- Smelter, Converter;

- Oil & Gas: FCCU etc.

- Our ESP design will incorporate CFD for even distribution of gas inside ESP to ensure the complete utilization of collecting area.

- Unicon is having Expertise in Both Tumbling Type and Top Rapping System.

- We offer Spiral/Rigid Emitting Electrodes to ensure the proper Corona generation inside the ESP for better collection efficiency.

- Individual Collecting electrodes are suspended from top to form a curtain. This also ensures that the Collecting system is not bulky and thus ensures good rapping characteristics.

- Unicon have supplied more than 300 numbers of ESP for Boiler. By the years, Unicon had accrued expertise in installing ESP for Boiler which are using fuels like Coal, Bagasse, Spent wash, Slop, Dolochar, Pet Cock, Rice Husk, Rice Straw, Wood Chips, Saw Dust, Chilly Spent, etc,.

Special features of our ESP(s)

- Proven Particulate Matter Removal 10mg/Nm3

- High Availability

- Low Maintenance

- Reduced breakdown

- Most Economical Design

- Lower Operating Cost

- Optimum Performance under Varying Load Conditions

- Optimum Power Consumption in Operation

- Next Generation Electronic Controllers

- Minimum Horizontal Space Occupation in the Project