DynaPerm

DynaPerm is a system for enhanced filtration of particles from liquids. Laboratory experiments have produced flux rate increases of a factor of 50 over conventional cross- flow filtration with comparable or improved effluent quality. The initial efforts to develop the technology were funded by Small Business Innovation Research (SBIR) awards from the National Science Foundation.

DynaPerm is based on a cross-flow micro filtration concept which utilizes thick-walled micro porous plastic tubes. The pore structure and micron range pore sizes are controlled during the manufacturing process. These tubes can be made from a variety of extrudable thermoplastics, are rugged, and chemically and biologically inert. A conventional cross-flow filtration technology, HYDROPERM, using these micro porous tubes has been successfully used commercially for the nearly complete removal of suspended solids and primarily toxic heavy metals. Example results are shown in the table below.

DynaPerm entails innovative concepts to greatly increase the efficiency and economy of particle removal from liquid by combining features of cyclone separation, flow interruption and cross-flow filtration thus employing multiple mechanisms of particle separation and enabling periodic shedding of the particle layer built up on the porous tube wall.

DynaPerm enables greatly increased flux rates with minimal down time for near complete removal of suspended particles down to the micron size.

DynaPerm has applications in many process stream and effluent treatment roles such as:

- Pretreatment, for suspended solids removal prior to reverse osmosis, carbon adsorption, or ion exchange treatment.

- Polishing, for removal of fine suspended solids after Chemical Analysis or biological treatment.

- Liquid Reuse, when this is otherwise impeded by the presence of suspended solids.

- In-Plant Processes, for valuable materials recovery.

- Toxic Heavy Metals removal when in suspended form.

- Treatment for discharge.

The figure presents results from laboratory experiments with water obtained from the water jet stripping of paint and rust from a bridge. The water contained suspended solids contaminants including lead at concentrations in the 600 ppm range. Measurements of the filtered water show nearly complete contaminant removal.

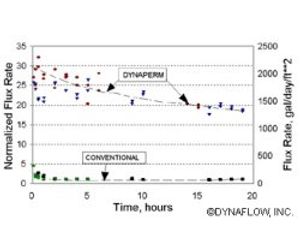

The figure compares the measured flux rates of the DynaPerm system with that of a conventional cross-flow filtration system HYDROPERM as a function of time at the same operating pressure and flow. The flux rates are presented both in gallons per day per square foot of tube area and normalized on the flux rate of the conventional system at 16 - 19 hours of operation. For both systems the flux rate initially decreases rapidly and then levels off to a slowly declining "plateau" after the first few hours of operation. The DynaPerm system has a flux rate increase in this plateau region of a factor of nearly 20 times that of the conventional system. Flux rates can be restored to initial values by cleaning.

These results demonstrate the potential for DynaPermto provide much more efficient, higher capacity, and more economical particle removal systems.