- Home

- Companies

- Zhengzhou Ecoshred Recycling Machinery ...

- Products

- Ecoshred - Model CSHB - Tire Pyrolysis ...

Ecoshred - Model CSHB -Tire Pyrolysis Machine

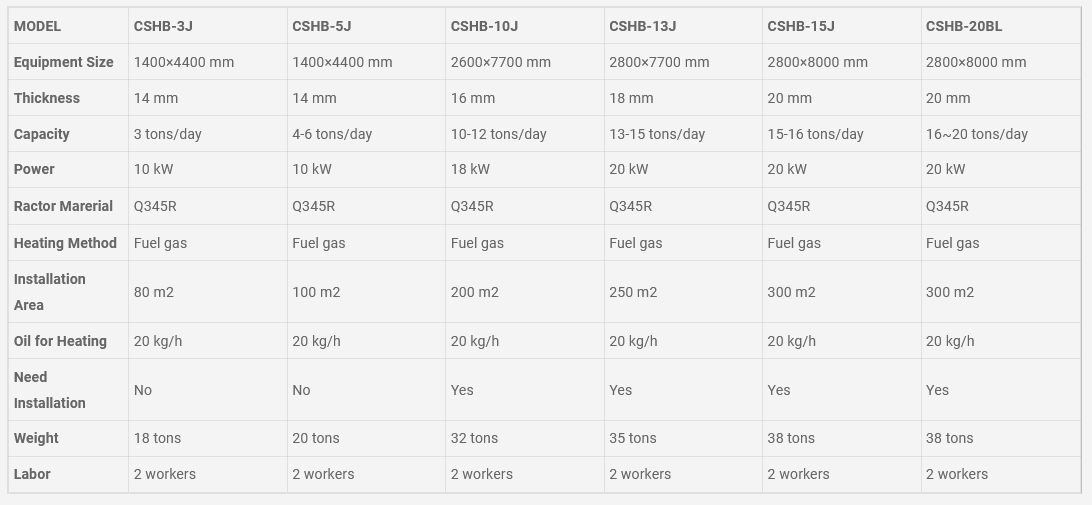

Ecoshred tire pyrolysis line (tire pyrolysis machine) is a chemical pyrolysis solution for converting waste tires into valuable products 45-50% oil, 30-35% carbon black, and 10% steel wires and processing capacity of 3 to 20 tons waste tires per day. ( Customized any higher capacity than 20 tons/day based on customer’s requirement.)

By utilizing Waste Tires, Plastic, Aluminum Plastic, Rubber, Oil Sludge as raw materials in the pyrolysis plant, it becomes possible to recycle the waste, thus helping to safeguard the environment by reducing waste accumulation. Moreover, investors can generate substantial profits by selling the by-products derived from the pyrolysis process.

ECOSHRED tire pyrolysis plants offer an effective method for recycling scrap tires and converting them into alternative energy sources without polluting the environment. To prevent air and water pollution, it is crucial to ensure that your waste tire pyrolysis facility incorporates a comprehensive set of systems such as smoke cleaning, tail gas cleaning, odor elimination, and water circulation. By adopting these measures, we can contribute to sustainable waste management practices while reducing the environmental impact caused by waste tire accumulation.

The Workflow Steps of a Tire Pyrolysis Plant

Raw Material Feeding

The first step in the pyrolysis process involves feeding the waste tires or plastic into a pyrolysis reactor using automatic feeding equipment.

Heating

Next, the fuel material, which may include LPG, tire oil, wood, natural gas, or coal produced from waste tires/plastic to fuel oil pyrolysis plant, is gently heated inside the pyrolysis reactor.

Separation of By-Products

Once the temperature reaches approximately 100°C (with the optimal output rate interval being 250-280°C), the oil gas starts to emit from the reactor. The manifold separates the heavy oil gas, which then liquefies and falls into a designated tank.

Cooling

After all the fuel oil has been produced, the reactor must undergo a cooling process. Once the temperature drops below 40 degrees Celsius, carbon black is automatically expelled.

Steel Wire Removal

If the source material consists of discarded tires, hooks are used to remove steel wires from the reactor once the temperature drops below 50 degrees Celsius.

Purification of Exhaust Gas

To ensure compliance with emission standards, any remaining exhaust gas can be purified using a smoke cleaning system.