They are one type of screens used in small and large scale purification plants and by-pass channels. Bar screens are named fine screen and coarse screen depending on the distance between bars. Generally, they have 10-30 mm screening bar distance.

Generally in domestic and industrial waste-water plants, water supply stations,and water purification plants, bar screens used for protecting pomps, valves, condenser plates, pipe lines and other connections against damaging and closing from various objects.

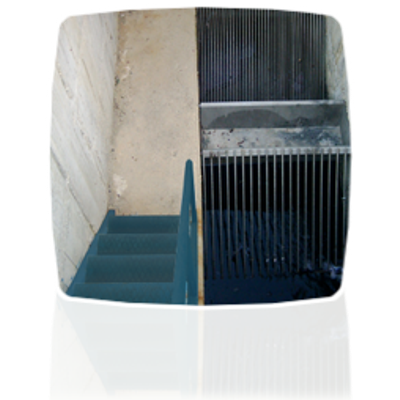

Bar screens are installed to the bottom of channel with 600 -700 inclination. Screen is generally composed of cleaning rake and waste reservoir. They are used for keeping the particles that dimensions are bigger than distance between bars. Frequency of cleaning depends on quantity of matter coming with waste-water.

EKOPOL Ltd , manufactures bar screens from stainless steel as a standard, but optionally dipping galvanized material or carbon steel covered by epoxy.