Norman Noble, Inc.

- Home

- Companies

- Norman Noble, Inc.

- Products

- Norman Noble - Electrical Discharge ...

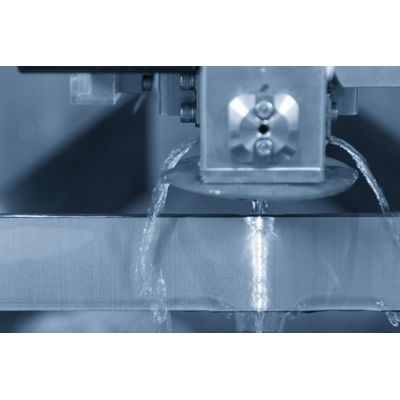

Norman Noble - Electrical Discharge Machining (EDM) Technology

Electrical Discharge Machining is used in medtech manufacturing for parts made from exotic materials with critical features that cannot be manufactured using traditional machine tool equipment. EDM is a non-contact machining process that provides accuracy and repeatability of +/-.0001”, and can be used in making recessed or angled cuts.

Most popular related searches

- Over 40 years of experience

- Wire and sinker Electrical Discharge Machining

- Specializing in exotic materials including nitinol and tungsten

- Micro hole drilling

- Norman Noble’s experience and capabilities with wire and conventional EDM is unmatched in the industry.

- Exceptional accuracy and repeatability

- Specializing in machining components from exotic materials

- Our extensive capacity includes over 40 Wire and Plunge EDM machines.

- Our experienced team of engineers works within our Process Development Centers (PDCs) to develop and validate cost-effective manufacturing methods required to produce prototype parts for our customers’ medtech product innovations.

- Multi Leaf Collimator (MLC) Housings

- MLC Tungsten Leaves

- Components for Structural Heart Implants

- Vascular Implants and Devices

- Orthopedic Implants and Devices

- Aerospace Satellite Housings and Gyroscope Components

- Stainless

- Carbon Steel

- Tool Steel

- High Nickel Alloys

- Titanium

- Nitinol

- Aluminum

- Co-Cr

- Tungsten