- Home

- Companies

- BIOGEST AG

- Products

- Biogest - Model Type EGAR - Electrical ...

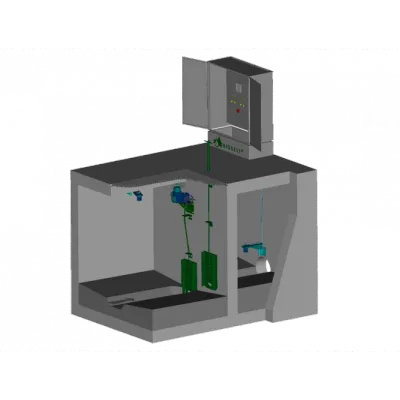

Biogest - Model Type EGAR -Electrical Flow Regulator for Rainwater Management

To prevent hydraulic overloading of sewer systems and the connected sewage treatment facilities, rain retention systems must be created. These have the task of buffering the mixed water that drains away in considerable quantities in rainy weather and throttling it on. Suitable technical solutions have been found to protect the following facilities, which ensure in a safe manner that constant runoff quantities are ensured in the run-off of a rain congestion system. Only such a measure leads to the desired result that the flow rate remains constant regardless of the accumulation height of a rain retention system.

The Electrical Flow Regulator Type EGAR was developed precisely for these requirements.

The regulator is fully open in dry weather. If the water level exceeds a certain height in rainy weather, the regulator is activated. The electric drive is actuated and closes the regulator until the slide plate position belonging to the accumulation height has been reached. The electronic controller constantly compares the measured stowage height with the setpoint. The control process continues until the backflow in the containment room has been removed and the backwater height is below the set limit. If this is the case, the control slide opens automatically so that the full drainage cross-section is available.

If a blockage occurs during the control process, this inevitably reduces the flow rate. This in turn leads to an automatic raising of the slide plate – if necessary – until the control slide is fully opened. After the throttle cross-section is flushed out and the flow rate increases spontaneously, the control slide moves back into its control position. In the case of backwater from underwater, the water level difference is recalculated and the target discharge volume is adjusted.

-

Simple function check in dry weather

-

Vertical Q / H characteristic

-

Active throttle device according to DWA A111 / A166

-

Backflow detection and inclusion in the control strategy

-

Preparation for telecontrol

-

Stepless adjustment of the target discharge quantity

-

Programming of various control strategies

-

Automatic regeneration in case of blockage