- Home

- Companies

- OriginClear Inc.

- Products

- Clean-Frac - Model Petro - Electro ...

Clean-Frac - Model Petro -Electro Water Separation (EWS)

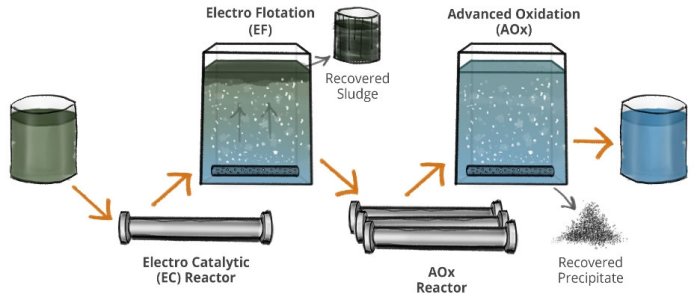

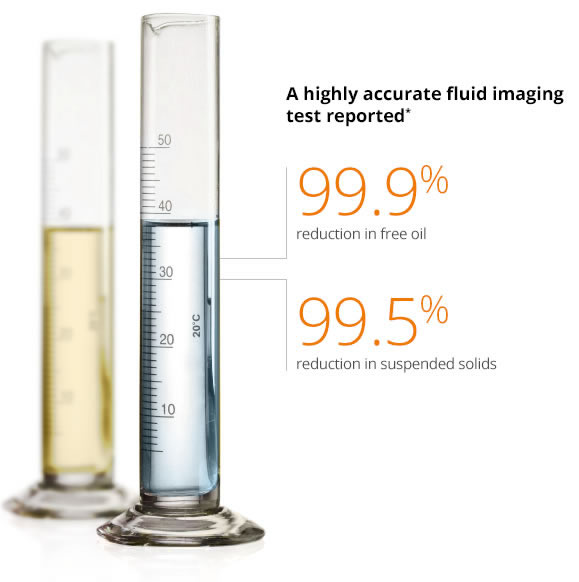

Electro Water Separation™ (EWS) is a highly scalable, continuous process that uses electricity in small, programmed doses to gather up oils and suspended solids, for an easy removal via mechanical raking off the surface of water.

EWS for Petro, is a continuous, chemical-free, low-energy process. Exhaustive testing has indicated that Specific Energy Consumption averages 5.1 kWh/kgal of water treated.

Assuming an energy cost of $0.15 per kWh, the energy cost of operating the EWS technology is estimated at $0.03 per barrel of water treated.

The designs incorporated in EWS technology are unlike other electro-coagulation (EC) systems tried over the years.

Other EC Approaches

Earlier EC generations have historically used heavy steel plates as the anode and cathode, with wide separation. The wide separation requires high power to achieve the dosage rates required for coagulation.

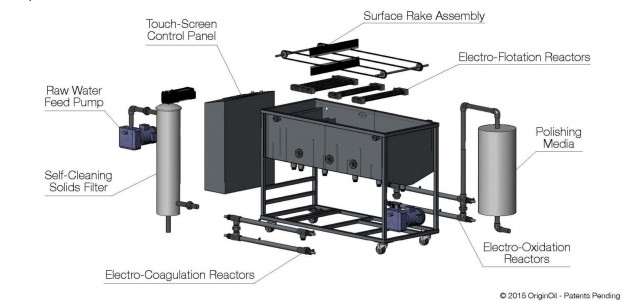

Typical EC systems have been stand-alone systems with separate pieces of equipment for gravity separation and disinfection. EWS integrates these functions into one stand-alone piece of equipment with SCADA control over all three technologies.

Our EC Approach

Instead, the EWS electro-coagulation reactors use an outer tube and an inner rod as the cathode and anode with the water flowing through the annular space.

The resultant narrow annular gap and high mass transfer rate minimizes the power necessary to achieve coagulation dosage rates. The high mass transfer rates also prevents scaling.

As a result of the above designs, the EWS EC reactors require far less power with an estimated Selective Energy Consumption of 0.28kWh per barrel of water.

Less anode consumption is seen, and the anodes are far easier to replace and maintain.

Our Electro-Flotation Approach

EWS electro-flotation technology utilizes non-donating anodes and cathodes to generate micro-bubbles over the complete volume of water in the flotation chamber. These microbubbles are small enough to embed or attached themselves to the coalesced oil and suspended solid particles.

The flotation chamber itself is also divided into four flotation or separation chambers each which separates larger percentage of the oil and solids leaving progressively clearer water.

Electro-Oxidation vs. UV

The same bank of EC reactors may also utilize reactors with non-donating anodes that generate oxidizing chlorine compounds that both disinfect bacteria and oxidize precipitable ions and metals.

This technology is known as electro-oxidation, which also occurs in the flotation stage of our donating anode configurations. By comparison, other systems for bacteria disinfection typically rely on UV lights.

Superiority over DAF

Dissolved Air Flotation (DAF) systems have two major disadvantages when compared to EWS.First, they depend on chemical coagulant additions for separation.

Second, they recirculate and expose only about 10% of the water to the gases that float the contaminants to the surface of the water.

Equipment suppliers who have technology that would benefit from EWS’s pretreatment technology, and system integrators who want to utilize EWS’s pretreatment technology, can license EWS on a private label basis.

EWS for Petro technology removes up to 99.9% of all free, dispersed and emulsified oil, and 99.5% of suspended solids from oil & gas wastewater, while also removing certain dissolved contaminants that will co-precipitate, and continuously disinfecting bacteria.

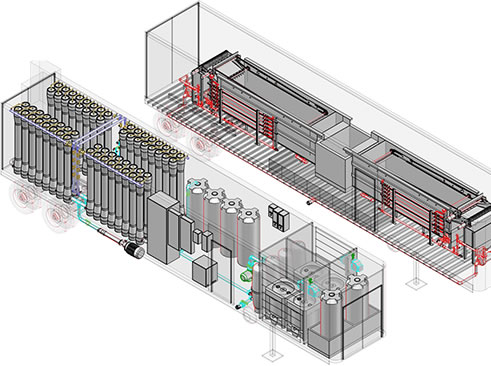

EWS technology with ‘heavies’ removal on the front end, intelligent controls, and a final post-polishing system, all in a single product.

EWS systems have been designed to include a common SCADA control system with touch screen which will allow automatic control of the process as well as remote monitoring and alarms.

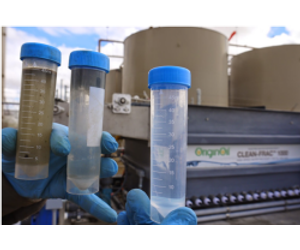

EWS for Petro is based on successful testing in a wide range of produced and frac flowback waters in the gas fields of western Colorado, West Texas intermediate oil fields and currently in the Monterey heavy oil fields of California.

Each of these waters has been unique, but EWS technology has proven flexible and robust enough to handle these widely varying challenges.

In the Monterey Shale, third party lab results confirmed that EWS reduced all measures of non-soluble contamination to very low, or undetectable levels.

- Turbidity reduced by 99.96%

- Total suspended solids reduced by 97%

- Total recoverable petroleum hydrocarbons reduced by 97%

- Biological oxygen demand reduced by 71%

- Chemical oxygen demand reduced by 92%

- Diesel range organics reduced by 99.3%

- Gasoline range organics reduced by 86%

- Motor oil range organics reduced by 99.5%