- Home

- Companies

- Geodesign Barriers, Inc

- Products

- Geodesign - Model E41 and E61 - ...

Geodesign - Model E41 and E61 -Elemental Flood Barrier

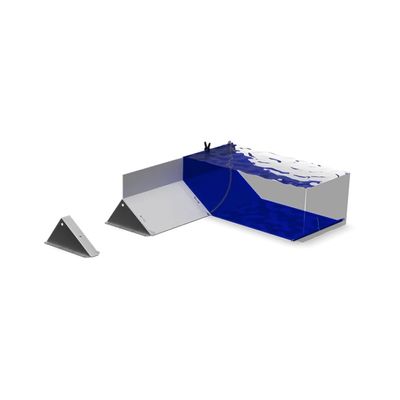

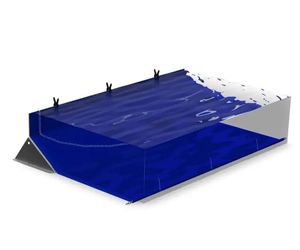

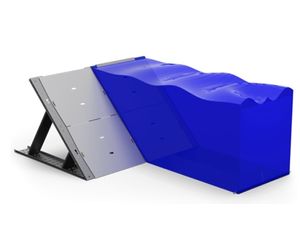

The Elemental model is our smallest barrier model and caters for those lower dam heights: 41cm, 51cm and 61cm. Even minor flash floods can ruin homes, businesses and cause traffic chaos. It is often vital to quickly divert the flow of surface water. As the Elemental flood barrier consists of just two metal parts, it is incredibly quick and easy to deploy, even for one person. You can stack around 50 m in 1m3 – in the corner of a garage or shed. Dam height 41 - 61 cm.

- Maximum Dam height: 41 - 61 cm

- Set up time 100 m /5 persons: 30 minutes

- Footprint barrier: 42 - 70 cm

- Section Width (ctc): 91.4 - 100 cm

- Barrier support Weight: 1 - 4 kg

Available models:

- E41

- E61

The Elemental flood barrier system is designed with practicality in mind, catering for dam heights of 0.41m and 0.61m. Flash floods can be disruptive, but with its two-part metal design, deploying long lines of flood barriers becomes straightforward and quick with the Elemental barrier. For storage concerns, note that up to 1 km of the Elemental barrier can fit neatly into a 20 ft container.

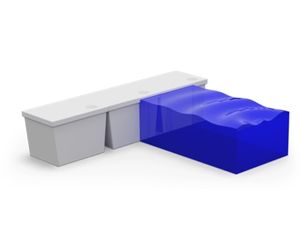

The Elemental flood barrier system is meticulously crafted to offer robust protection against floodwaters rising up to 61 cm. It showcases a streamlined design comprising just two components: a durable metal support and a metal sheet. Unlike the other ranges in the Geodesign series, there is no need to unfold supports; instead, you simply position them.

This efficient design facilitates rapid installation over extended lengths, ensuring timely flood prevention. Beyond merely acting as a barrier against rising water, the Elemental barrier can stand up against the rush of water during flash floods – common in urban areas due to surface water accumulation on streets and roads.

But the utility of the Elemental system doesn`t stop at flood protection. It can do more. Its versatile design means it can be made into reservoirs for various liquids. Owing to its adaptive nature, it can be made into diverse shapes and sizes for all sorts of temporary containment needs, like for example water, oil spillage, slurry or sand. Furthermore, the Elemental flood barrier does not take up much storage space: a crate with 50 meters of barrier fits in just 1 m2, and 1km of barrier can be neatly packed into a standard 20 ft container.

Dam height 41 cm

E41 Elemental

Flood Barrier

- Max water column: 0.41 m

- Section width: (ctc): 100 cm

- Setup time: (100 meters / 6 persons): 30 mins

- Footprint: (With poly liner): 100 cm

- Footprint: (Only barrier): 42 cm

- Weight / section: 10 kg

- Storage vol: (One set, 50 sections): 0.8 m3

Dam height 61 cm

E61 Elemental

- Flood Barrier

- Max water column: 0.61 m

- Section width: (ctc): 100 cm

- Setup time: (100 meters / 6 persons): 30 mins

- Footprint: (With poly liner): 200 cm

- Footprint: (Only barrier): 70 cm

- Weight / section: 14 kg

- Storage vol: (One set, 33 sections): 1.35 m3

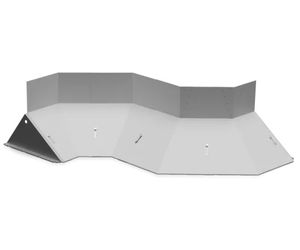

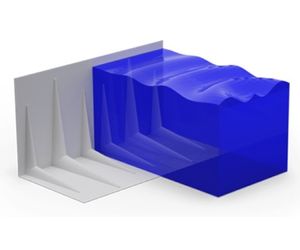

The Elemental Flood Barrier is ingeniously designed to seamlessly integrate with any landscape, effortlessly contouring around permanent obstructions in its path. With our innovative corner panels, a versatile wall connection kit, and intrinsic system flexibility, the Elemental Flood Barrier stands robust, reliable, and ready to tackle any challenge.

Whether you`re meeting midway from two ends or targeting a precise endpoint, our design allows for intuitive adjustments. Simply overlap two panels and secure them at one end with the mount button lock.

From curbs and steps to the unpredictability of uneven terrains, the use of thin high-strength steel sheets ensures the barrier remains steadfast and effective, adapting effortlessly to varied landscapes.

Our meticulously crafted corner panels enable sharp 45-degree inner and outer bends, making angular adjustments a breeze.

Align your barrier flawlessly against a wall. Our specialized wall connection kit ensures a secure attachment to any vertical foundation, all while reducing water seepage to a minimum.

The Elemental Flood Barrier isn`t just versatile with its own kin. It`s equally adaptable with our taller Industrial series, expanding its scope of utility.

Even with straight sections, our barrier boasts the ability to gracefully curve with a generous 90-degree turn and a radius of 10 meters—once again highlighting the modular design`s flexibility and the efficiency of our thin steel panels.

The Elemental Flood Barrier, the most compact offering in Geodesign`s product range, combines engineering precision with user-friendly design. Crafted for swift and simple installation, it does away with the need for tools, heavy machinery, or a large team. This advanced steel barrier emerges as the go-to choice for those not only aiming to counteract rising waters during floods but also desiring to efficiently direct water flow in urban areas during unexpected flash floods.

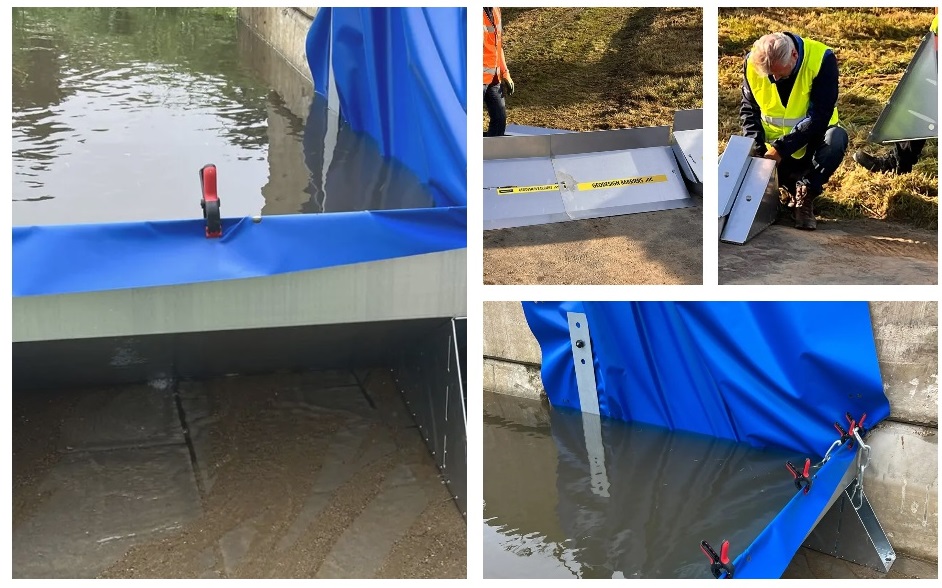

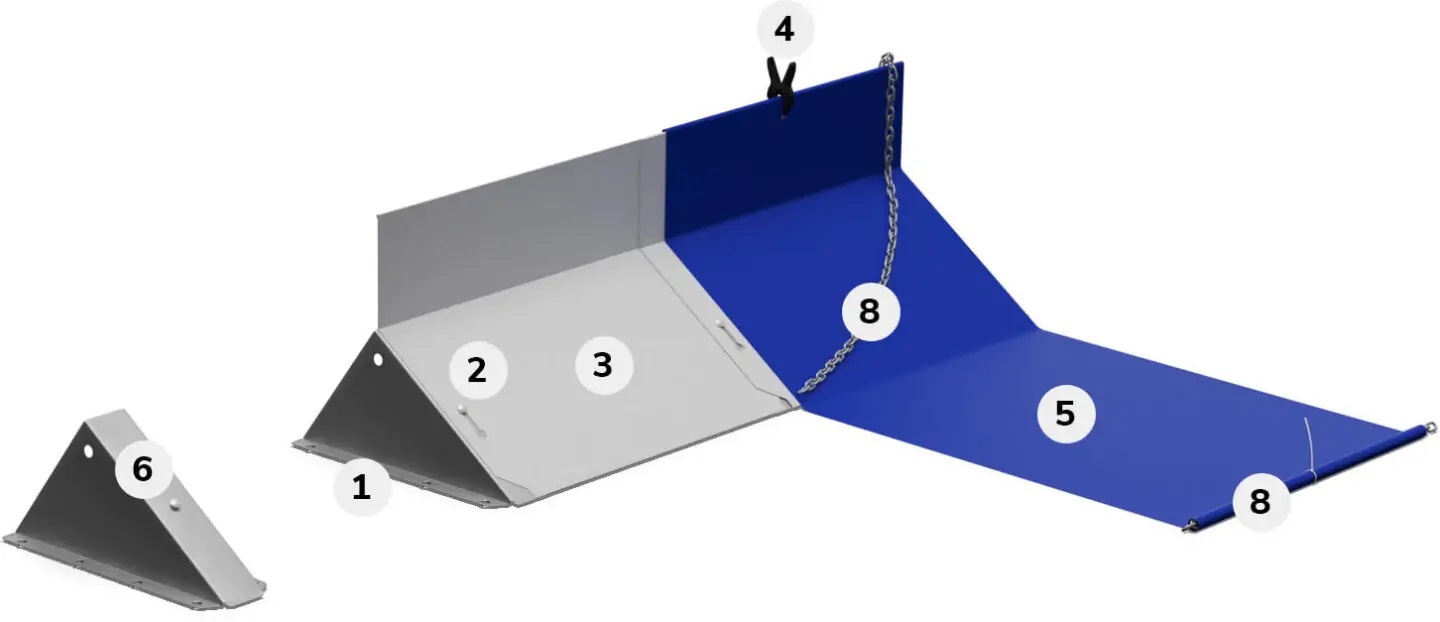

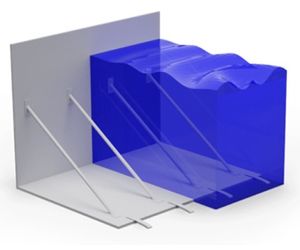

Efficiently set the supports at intervals of 100 cm, delineating the desired path of the barrier.

Simply align the panel cutouts with the prominent mount knobs on the supports. Overlap adjacent panels for a seamless fit.

Unroll the poly membrane across the barrier`s length and secure it using spring clamps. In windy conditions, enhance stability by adding chain ballasts.

Allow incoming flood water to make contact with the poly membrane and the barrier`s surface. The barrier ingeniously uses the force of the water to anchor itself securely in place.

The Elemental Series encompasses two modular steel flood barriers, each crafted with sections of tilted panels capable of halting floodwaters up to 61 cm. The E-barrier not only offers swift and straightforward deployment but also boasts optimal logistical features and an extended durability. Designed to satisfy the stringent requirements of governmental rapid flood protection, it`s compact enough to fit comfortably within a typical homeowner`s garage or garden shed. This robust steel barrier is erected swiftly, anchors itself, and resolutely stands against rapid water currents and overflows.

Beneath the bottom beam, protruding steel collars are strategically placed to secure a grip, enhancing the friction between the self-anchored barrier and the ground surface.

A smart, innovative solution that accelerates assembly while boosting flexibility.

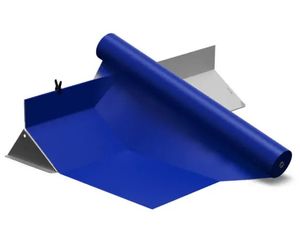

Weighing just 7 kg per E61-panel, this 1 mm hot-dip galvanized steel sheet is both user-friendly and storage-efficient. Crafted from Dual Phase Steel by SSAB in Sweden, it offers superior tensile strength and corrosion resistance.

Clamps Highly effective spring clamps exert a powerful grip, ensuring the poly membrane remains firmly in place.

5. Optimized Poly Membrane

Our high-density polyethylene membrane, enhanced with laminate coating, is designed to minimize leakage and amplify its self-anchoring prowess.

6. Space-Saving Stackable Supports

Triangular barrier supports are designed for stacking, drastically reducing storage space. Their reclined front incorporates a mount knob for rapid assembly, while the bottom anchor wings feature sharp collars to provide maximum ground friction.

7. Ultra High-Strength Steel Components

All pivotal components of the Elemental Barrier are crafted from high-strength and ultra-high-strength steel with micro-alloy elements. Every steel piece undergoes a hot-dip galvanization process with a zinc coating, ensuring corrosion protection.

8. Galvanized Steel Chains with Carabiners

These 5 mm x 5 m chains not only serve as ballast but also ensure the membrane remains grounded before the water reaches the barrier.

The Elemental Flood Barrier boasts a stackable design, ensuring space-efficient storage and swift transportation readiness for flood situations. A span of 50 meters, divided into 50 sections, of the Elemental Flood Barrier occupies a mere 1.3 m^2. For those seeking peak efficiency, the Elemental can be packed in our custom-designed metal crates. This meticulous design allows a staggering 1000 meters of the Elemental barrier to fit snugly within a standard 20-foot container.

When it comes to purchasing a flood barrier, there are many factors to consider. While each flooding event is unique, taking a comprehensive approach to understanding your specific situation can increase your chances of finding the right solution. With our 25 years of experience, we want to assist you in making an informed decision. To aid you in this process, we have compiled a list of crucial criteria to consider:

Ensure that any flood barrier system you consider is certified by a trusted third party for reliability. A failing flood barrier can have catastrophic consequences, causing significant damage and endangering people and property.

Verify that the barrier system has quality certificates from a reputable third party. Flood operation activities and safety should always require certified products with rigorous testing and evaluation procedures as the standard.

When researching flood protection systems, it`s crucial to look for real-world references that demonstrate the system`s performance in contact with actual floodwater.

It`s important to choose a system that has been proven effective in repeated flooding situations. Make sure to check for visible proof of the flood barrier withstanding floodwater, as products and systems displayed in controlled environments or on dry land may not be sufficient evidence of their capacity to withstand real flood situations.

When it comes to flood systems that require filling materials such as sand, water, gravel, or air, it`s important to consider all logistics involved to ensure full operational function.

This includes factors such as accessibility and handling of the filling material, which may require heavy machinery, manpower, pumps, and sufficient pumping capacity to supply the required amount of material in a timely manner to the designated flood area. Calculating these logistics and associated costs is crucial when comparing different flood solutions. In addition, it`s important to note that materials like sand and water can become contaminated after a flood, and proper handling and disposal procedures must be followed to ensure responsible post-flood management.

It`s important to consider the impact on your site if the flood barrier system needs to be anchored. This may involve additional costs or disruptions to the ground surface.

Additionally, it`s essential to factor in the expenses of reinstating the ground surface after a flooding event. These considerations can help you evaluate the total cost and feasibility of a flood barrier system for your site.

It`s crucial to assess whether a flood barrier system can withstand the challenges posed by tough terrain and real-world conditions. Uneven surfaces, steps, slopes, urban street furniture, overtopping, and floating debris are just a few of the obstacles that the system may encounter.

By taking these factors into consideration, you can ensure that the flood barrier you choose will perform effectively in the face of adversity.

When buying flood barriers, consider the price in relation to the expected lifespan, and the impact of usage, sunlight, water, and temperature. The cost of deploying, installing, and maintaining the barrier, including filling materials, spare parts, repairs, training, deployment equipment...

...and personnel, should also be factored into the total cost of flood protection. This helps you make a cost-effective investment in flood protection.

When it comes to flood barriers, a well-designed setup is essential for a smooth and easy set-up and take-down process. A quick installation time is critical to ensure that the flood protection is in place before flooding occurs, and it can also help to conserve resources.

However, it`s important to note that some systems may look straightforward but can be cumbersome in practice due to various connections and small parts that need to be assembled into a coherent barrier. Therefore, it`s crucial to select a flood barrier system that has been carefully thought out and designed to ensure a hassle-free setup process.

When floods occur, flood defenses may become exposed to contaminated water. This can pose a challenge for flood barriers that rely on materials like sand or water, as they may become contaminated as well.

Additionally, some plastic-based systems cannot be effectively cleaned if they come into contact with contaminated water and may need to be replaced entirely. To ensure that you are well equipped to handle such situations, it is crucial to choose a flood barrier that can effectively manage and mitigate the impact of contaminated water.

There are certain costs associated with maintaining and handling flood barrier systems to ensure that they are ready for the next flood. Activities such as system inspections, removal, and clean-up can pose significant challenges if the design of the system does not facilitate easy access and maintenance.

For example, clogged fabrics that cannot be reused or sealed tubes that are difficult to dry out from contaminated water can make post-maintenance time-consuming and costly. Additionally, it`s important to consider repair, replacement, and proper disposal of damaged parts.

To make an informed decision, it`s recommended that you ask the supplier for more details or preferably references from other users of the system. By doing so, you can ensure that the system you choose is reliable and cost-effective in the long run.

When it comes to flood barriers, the market offers a wide range of options. Regardless of the type you choose, however, all flood barriers share the ability to hold back water in various ways and to varying degrees without being dislodged by the pressure exerted by the water.

These methods can generally be classified into four distinct concepts, each with its own strengths and limitations. By understanding these concepts, you can make an informed decision when selecting a flood barrier.

Filling material

The concept behind these types of flood barriers is to use a filling material such as sand, water, gravel, or stones to provide weight and create a flood defence system that stays in place. To install this type of barrier, trucks need transport the filling material to the site, where it is placed within the barrier`s structure. If water is used as the filling material, it`s important to have access to a water source prior to a flood event.

VS.

No filling

These types of flood barrier systems are designed to create an anchoring force that is stronger than the pushing force of floodwaters. As a result, no additional filling material, such as sand or water, is required to secure the barrier in place.

Anchored

In order to withstand the pushing forces of floodwaters, some flood barrier systems require additional anchoring beyond their own construction. This is typically accomplished by fastening the barrier to the ground using various methods.

VS.

Freestanding

The design and/or weight of the system are such that it has sufficient anchoring power to remain stable and in place without the need for additional anchoring.

There are many types of flood barriers available on the market, each with its own unique form and operational characteristics. By considering the four different concepts presented - filling material vs. no filling material and freestanding vs. anchored - we can explore the various flood barriers available on the market in more detail. Below is a brief description of some of the flood barrier types.

Gabions are cellular barriers that can be connected together to form a flood barrier line. They are typically constructed with permeable materials like geo-fabric and reinforced with frames made of wire mesh and pins. To provide stability against floodwaters, gabions are filled with materials such as sand, water, or gravel stones. These systems are considered gravity dams because they rely on the weight and shape of the filling material for stability.

- The height of the system can be increased during use, making it flexible and adaptable to changing flood conditions.

- However, installing gabions can be time-consuming because it requires a large amount of filling material.

- Additionally, heavy machinery such as trucks and water pumps are needed to provide the filling materials.

- After a flood event, disposing of large volumes of contaminated filling material can be challenging.

- Moreover, clogging of the fabric material can make it difficult to clean, and the gabions may not be reusable.

These flood barriers consist of large, prefabricated tubes made of reinforced PVC plastic. The tubes are connected to each other to form a flood barrier line. Because they rely on the weight and shape of the filling material, these systems are considered gravity dams and can provide stability against floodwaters.

Installing the system requires machinery such as trucks and water pumps to fill the tubes with sand, water, or another suitable material. Water-filled tubes are generally suitable for long lengths of protection close to a water source.

- One advantage of these systems is that they require relatively small storage space.

- However, they must be deployed close to a water source, which can limit their use in some areas.

- These systems are highly susceptible to vandalism or damage by sharp objects.

- Additionally, any tears or punctures can rapidly lead to failure of the whole system, which can compromise its effectiveness.

- Finally, the tubes require relatively flat surfaces for deployment, which may not be feasible in all locations.

These flood barriers are made up of rigid, self-supporting elements that interlock to form a continuous wall. The elements are typically prefabricated and jointed, with an L-shaped structure that utilizes the weight of the floodwater to create an anchoring force. However, additional anchoring may be required to prevent movement, which could involve ground investigation and/or pre-installation. This anchoring can make these systems less versatile compared to freestanding systems. The front edge of the system is designed with a sealing list to prevent seepage.

- One advantage of these systems is their relatively small footprint on the ground.

- However, the need for ground anchoring can make the preparation of the flood protection process similar to demountable systems.

- These systems are not suitable for use on uneven ground.

- Finally, the longer deployment time needed for anchoring in the ground may be a disadvantage in some situations.

These flood barriers consist of rigid self-supporting elements that are connected to form a continuous flood barrier wall, similar to anchored vertical walls. The L-shaped structure uses the weight of floodwater over the front edge of the system to provide stability and create a seal towards the ground.

However, it`s important to note that:

- These barriers may not be suitable for natural surfaces like grassland or arable land, as seepage under these systems can be significant, especially in uneven terrain due to their rigidity.

- These barriers are best suited for diverting water flows rather than withholding water due to the high seepage underneath the system.

- While they are quick and easy to deploy, it is essential to consider their limitations.

- They may not work for higher flood levels, and they are not suitable for uneven ground.

- Despite being cheap and easy to deploy, the high leakage underneath the rigid elements must be taken into account when selecting the right flood protection system.

Frame barriers are a modular flood barrier system consisting of rigid frames covered with impermeable materials. They are freestanding and use the weight of the water for stability, making them self-anchoring. This engineered construction allows them to withstand floodwater and do well in uneven terrain. Assembling them is easy and follows a logical step-by-step procedure, and no parts are heavier than two persons can carry.

Key features of frame barriers:

- Modular barrier made of rigid frames and impermeable materials.

- Freestanding and self-anchoring, using water weight for stability.

- Engineered construction that withstands floodwater and works well in uneven terrain.

- Easy assembly with logical, step-by-step procedure.

- Lightweight parts that are easy to carry.

These barriers are designed to protect against floodwater and are composed of free-standing sections made of flexible and impermeable plastic. The system is anchored to the ground for stability, and the floodwater itself is used as filling material. Stability is achieved through the weight of the water acting on a long skirt located in front of the system. During critical moments, manual labor is required to ensure that the floodwater enters the system correctly.

- Uses floodwater as filling material

- Requires manual labor during critical moments

- Comes in fixed lengths

- Risk of collapsing if floodwater overtops

- construction

- Not very flexible

These flood barriers consist of water-filled containers that are cellular in structure and can be linked together to form a line of defense against floodwater. They are often made of impermeable materials such as polyester, polyethylene, and plastic, and achieve stability through their shape and weight of the filling material. However, they are prone to sliding when overtopped. These gravity dams require machinery such as trucks and water pumps for installation, and the mobilization and deployment process is affected accordingly. Minor leaks can usually be repaired in service. The system has a rigid bottom and is not suitable for uneven terrains.

- Made of impermeable materials such as polyester, polyethylene, and plastic.

- Achieves stability through the shape and weight of the filling material.

- Prone to sliding when overtopped.

- Requires machinery for installation.

- Not suitable for uneven terrains and has a rigid bottom.

What Specific Knowledge is Required to Use the Flood Barriers?

Using Geodesign Flood Barriers effectively doesn`t require a specialized professional background. To ensure competent deployment, we recommend that at least two members from the responsible authority undergo proper training in temporary flood protection, in addition to receiving product-specific instruction.

The beauty of the Geodesign Flood Barrier system lies in its simplicity. Our comprehensive instruction manual is designed so that individuals without specialized training can assemble the barrier correctly. The assembly process is manual, eliminating the need for tools or heavy machinery. Additionally, there are no loose parts that require complex mounting onto the steel structure.

In essence, the combination of straightforward instructions and the system`s design makes it accessible for users with various levels of experience, ensuring reliable and efficient setup during crucial times.

What Underlay Can the Flood Barriers Be Placed On?

The Geodesign Barrier system is designed to be versatile and adaptable, capable of being deployed effectively on a variety of surfaces that provide sufficient friction. These include tarmac, various sizes of gravel, grass, clay, and even mud.

Given that both urban and rural environments often present challenges like uneven terrain and solid obstacles, the system`s flexibility is a significant advantage. It can be used effectively on almost any type of ground surface. The system`s ability to build corners and connect to walls allows it to protect almost any building or infrastructure asset, regardless of its location. It also handles shifts in level, such as curbs, steps, or uneven ground, with ease.

In cases where the underlay is smooth concrete, which provides less natural friction, an anchor pin is used to help stabilize the support. This ensures that the barrier remains secure and effective even on less ideal surfaces.

In summary, the Geodesign Barrier system is highly adaptable, making it suitable for a wide range of terrains and surface types, ensuring reliable flood protection in diverse conditions.

How Much Water Pressure Can the Flood Barrier Resist?

Geodesign Flood Barriers are engineered to be highly stable and withstand significant water pressure. They maintain stability all the way to the top, offering maximum protection at their designated water depth. These barriers are designed to be stable at 100% full static load, and they also incorporate a structural factor of safety that accounts for added dynamic loads caused by lateral currents and waves.

The barriers have undergone rigorous testing and are certified according to Kitemark BS 851188-2 standards. They have been proven to resist a Designated Maximum Water Depth (DMWD) of 1.00 meter. This certification ensures that they meet stringent safety and performance criteria.

Additionally, the barriers are FM approved, meaning they comply with the high standards set by FM Global, a leading property insurance and risk management organization. This approval signifies that the barriers are reliable, effective, and capable of withstanding the pressures and challenges posed by flood conditions.

In summary, Geodesign Flood Barriers are robustly designed and thoroughly tested to resist high water pressure, ensuring effective flood protection in demanding scenarios.

Is There Any Risk of Damage, Theft, or Vandalism?

Geodesign Flood Barriers are designed with durability in mind. Their underlying structure is made of high-strength steel, which significantly reduces the risk of damage from floating debris and makes them less susceptible to vandalism. Sharp objects such as knives or any floating debris are unlikely to cause severe damage that would compromise the barriers` functionality.

However, despite their robustness, we still recommend that the flood barrier setup be monitored throughout the duration of the flood. This is important not only to stay alert and ensure a successful flood fighting operation but also to minimize the potential risk of vandalism. The level of surveillance may vary based on the location and circumstances, but generally, it’s advisable to have someone responsible for inspecting the barrier regularly. This person should ensure that any necessary repair work is carried out promptly and effectively, maintaining the barrier`s integrity throughout its deployment.

In summary, while Geodesign Flood Barriers are built to withstand harsh conditions and resist damage, ongoing vigilance and maintenance are still crucial for optimal performance and security.

In the UK, Geodesign has been awarded the honorable duty of supplying the Environment Agency and the UK Army with flood protection barriers. The UK Flood Barriers are stored strategically placed depots throughout the country and military personel train regularly with deployment and usage. It is a combination of Geodesign’s steel and aluminum flood barriers as well as a number of high capacity flood pumps that have been selected to make up the nation’s flood defence. The testaments from the UK Environment Agencyrepresentatives have been undividedly positive after working with Geodesign Barriers. The steel structure instills trust and reliability, yet increase work speed and flexibility compared to inflatable water barriers.

Water barriers are flood barriers filled with water. No, we don’t offer an inflatable flood barrier – they are dangerous and unreliable as a concept – but we offer a steel canal that we fill with water to make it virtually impossible to move. A water barrier for homes with a dam height of 16 inches weighs more than 400 lbs per linear foot! Hurricanes and storms are not able to move the water barrier when a few yards of barrier have been deployed properly. Water barriers to prevent flooding after hurricanes are an ideal solution to an enormous problem.

Many home owners have approached us about home flood barriers in the last few years. Our solution is a real residential flood barrier made of high strength steel. It comes in dam height of 16, 24, 32 and 40 inches and is easily deployed and mounted by one man or woman. The barrier consist of the a-frame supports, the flood shields and waterproof membrane. No tools are needed and no part weighs more than 25 lbs. Just mount the steel plates to the supports by hanging them on the knobs located on the front beam of the barrier support. When the complete barrier is deployed, roll out the membrane along the barrier line and attach the sealer clips to the top of the flood shields to hold the membrane in its place.

A flood barrier is essentially a wall constructed to stop flood water from damaging property or entering an area. The first flood barriers were built with sandbags and required a lot of personel to erect. For decades, military and volunteers have been hauling these sand bags to build flood barriers around their but it has been slow, ineffective.

Unfortunately, we cannot control if, when or where flooding will occur. The nature of floods is very unpredictable and permanent walls and levees have rarely provided a good solution since flooding often occur in different places and with irregular time intervals. Instead, successful flood control has come to rely on temporary flood barriers, high performance flood pumps and a prompt response to the first flood warnings. The flood control barriers from Geodesign are being used an emergency response to flooding throughout the world today. Quick deployment and reliable, durable steel are success factors in continously diverting flood water from urban and rural areas.

A flood wall to stop water from entering your area or your building can easily be set up with Geodesign Flood Barriers. The inclination of the barriers require slightly more ground space to deploy the flood wall but it is freestanding and leaves no marks on the property after demounting.

The Geodesign Flood Barriers have been designed for flood rescue operations under the most difficult conditions imaginable. Since the start in 1995, numerous flood engineers, emergency managers, city planners and military personell have contributed with feedback to improve the products to what they are today: Quick, lightweight, low volume, strong, durable and versatile. The solution to flooding is here and ready to be deployed. Preparation, the right flood barrier and a prompt response are keys to success.

QUICK & EASY TO DEPLOY

No fill material, pre-installments or tools. The logical assembly of the Geodesign Barriers make them the fastest flood barriers to install.

OPTIMAL STORAGE AND TRANSPORT

With its ingenious design, the collapsible supports and thin flood shields enables optimal storage and transport. Our flood barriers are delivered in stackable steel crates.

ROBUST AND DURABLE

Reinforced high strength steel has a lifespan of 100+ years and withstands overtopping as well as hits from debris. Sound engineering keeps you safe and

25 YEARS OF EXPERIENCE

Our flood barriers are delivered with a complete flood protection plan for your property and a full day of training. Take advantage of our experience.

Temporary and demountable cofferdams have great advantages where there is a need for a quick dam with little to to no permanent marks on the site. It is a fast and efficient way of drying up riverbeds, lakes, ponds and even boat docks. With our temporary barriers, nothing is anchored to the ground and no tools are needed to create a stable and dry cofferdam in 10 foot deep water. We have 25 years of experience and the best product to offer a complete cofferdam at a competitive price. Ask us for details and pricing here.

A quick dam might sound like a simple, almost playful, idea of building a dam. The truth is that the forces applied to a flood barrier when used for building temporary dams are tremendous and the importance of a correct setup cannot be understated. However, speed is always a factor when problems with water need to be solved and a quick dam is exactly what we aim to deliver. With decades of experience and a superior product, Geodesign and its engineering partners are able to construct complete temporary dams within a few hours of work. We offer quick, secure and cost effective dams across America.

The development of flood control plans has evolved rapidly over the last 10 years. The notion that “nothing can be done about floods” has been changed with the emergence of flood control products. Today, most cities and towns in the western world that are prone to flooding, has some sort of flood control plan or flood control preparedness. Geodesign Barriers work together with clients to set up proper flood control measures, that involve everything from city planning and flood watch to flood barriers and pumps.

To plan for flood prevention and mitigate risk, one must assess the project as disaster relief and with a mindset of fighting back, much like fighting fires. Planning and preparation is absolute key to successful flood fighting and the best flood prevention plans contain training as well as flood protection products.

Flood barriers are a great solution to one of the oldest problems societies face – flooding. A market has emerged with plenty of alternatives to sand bags and most towns, communities and even house owners know that there are ways to protect their property and infra structure. Among the different options for flood protection, we strongly believe that flood barriers of steel should be atop your list. Steel is strong and withstands pressure from water and floating debris. Steel is durable and last a lifetime. Steel is also less susceptible to sabotage or accidents involving sharp object.

In recent years, the flooding after hurricanes Katrina, Harvey, Sandy and Irmahave caused enormous damages to American homes and infrastructure. The costs of hurricane Harvey is estimated at approximately $125 billion and the cost of hurricane Katrina stands even higher at $160 billion. It is clear that anything that can be done to reduce these damages will greatly help the local community, the home owners, the federal emergency resources and the state. Geodesign’s water barrier is a water canal that stands above ground weighs up to 1.2 tons per linear foot. In other words, an extremely heavy and stable water barrier that withstands hurricane type winds and protects against flooding.