- Home

- Companies

- ELICA PROcessing

- Products

- ELICA - Dehulling System for Oil ...

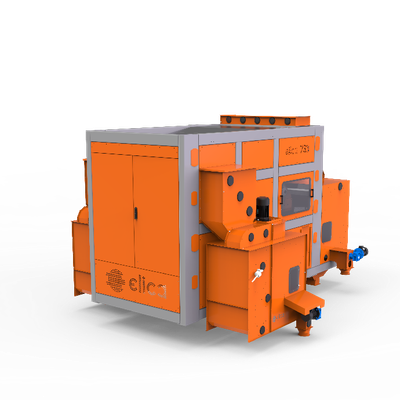

ELICA - Dehulling System for Oil Crushing Plants

Elica offers a compact and efficient dehulling system that is specifically designed for oil crushing plants, boasting a high capacity of up to 180 tons per day. Developed by Elica's engineering team, this system features a newly patented design with an upgraded impact frame. It ensures precise dehulling of sunflower and oat seeds while distributing material evenly along its width through adjustable feeder speed controls. A key element of the system is its remote control computer system, which facilitates process control without necessitating repeated cycles. Integrated with a magnetic separator, the system effectively removes ferrite particles from the material flow, prolonging the service life due to its use of wear-resistant materials. Maintenance is straightforward with easy access to servicing platforms. The system's performance remains high quality, adaptable with impact frame adjustments, and is dependent on the proportion of separated husk.

Compact system for dehulling with high capacity (up to 180 tons per day). New patented developed by Elica’s engineering team consisting of upgraded impact frame.

ELICA dehullers manage to distribute the incoming material evenly along its entire width by providing option to regulate the feeder’s speed. The equipment achieves high quality of the final product without the need of repeating the cycle. The system is provided with remote control computer system to control the whole process. The dehuller has a built-in magnetic separator to capture the ferrite particles contained in the material flow. The service life of the easily wear parts is extended due to the wear-resistant materials used in the production. The equipment is designed to be maintained fast and easy with an access to the servicing platform from a staircase.