- Home

- Companies

- QED Environmental Systems, Inc

- Products

- Eliminator - Remediation Bladder Pump

Eliminator - Remediation Bladder Pump

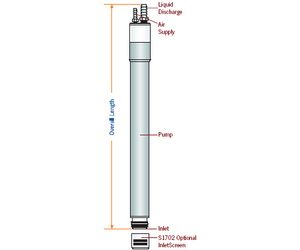

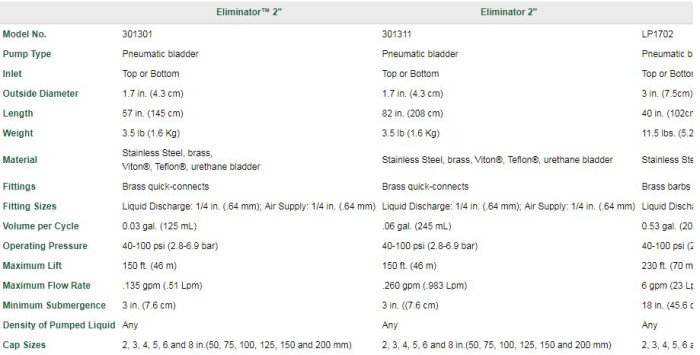

The Eliminator is a high capacity bladder pump designed for LNAPL and DNAPL removal in 2” (50 mm) and 4” (100 mm) wells. The Eliminator is also used to handle viscous contaminants, such as crude oil. The Eliminator uses a bladder of PTFE or elastomer to isolate the pump air supply from the pumped liquid. As a result, there is no contact between the drive air and the contaminated fluids inside the bladder and, therefore, no emissions of potentially contaminated air.

Eliminator pumps provide reliable top-inlet skimming or bottom-inlet pumping. A wide range of accessories is available, including “roving” well caps to allow accurate pump inlet positioning, and bladder replacement kits for easy field maintenance.

The Eliminator is powered by compressed air and requires an external timer based controller to control the air cycling ON and OFF to the bladder pump.

Compressed air is supplied directly to the Eliminator via an external controller.

When the bladder is squeezed from the outside by the compressed air, fluid within the bladder is forced out through a check valve at the top of the pump.

Then, when the air pressure around the bladder is exhausted, the bladder expands resuming its original shape. This pulls fluid into the bladder through either the top or bottom inlet, depending on the pump inlet configuration.

Flow optimization is simple too; rugged, dependable pumps and controllers (the solar/AC powered C100M and the all-pneumatic L360) deliver reliable operation without needing frequent attention or repair.

- 100% air-powered operation.

- No contact between drive air and contaminated fluids.

- Effective skimming of viscous hydrocarbons, such as crude oil.

- Available for 2” (50 mm) and 4” (100 mm) wells or larger.

The Eliminator is powered by compressed air and requires an external timer based controller to control the air cycling ON and OFF to the bladder pump.

Compressed air is supplied directly to the Eliminator via an external controller.

When the bladder is squeezed from the outside by the compressed air, fluid within the bladder is forced out through a check valve at the top of the pump.

Then, when the air pressure around the bladder is exhausted, the bladder expands resuming its original shape. This pulls fluid into the bladder through either the top or bottom inlet, depending on the pump inlet configuration.

The controller options for Eliminator include:

- The all-pneumatic L360, with settable refill and discharge times to match site conditions. The L360 cycle controller can be coupled with the L370 level controller to stop pump operation when liquid levels fall below the set point.

- The C100M electronic controller, which can be powered by its built-in solar panel or the included AC adapter. The C100M provides lots of flexibility in cycle times and settable “Off” periods, as well as economical low liquid level shutoff and tank-full float switches. The AC power source is required for continuous pump operation.