- Home

- Companies

- ENERCON GmbH

- Products

- ENERCON - Drive System

ENERCON - Drive System

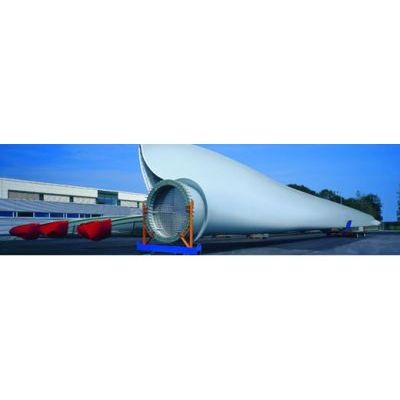

When it comes to yield, noise emission and stress minimisation, ENERCON’s rotor blade concept sets new standards in the wind energy sector. Because of their modified shape, the blades not only draw energy from the outer edges but also use the inner radius of the swept area, considerably increasing power output. The new rotor blades are also less susceptible to turbulence and provide an even flow along the entire length of the blade profile. In addition to the new design, the blade tips have also been improved to reduce noise emission and increase power output. Turbulence at the blade tips due to overpressure and underpressure is effectively eliminated in the rotor plane. The entire length of the blade is therefore utilised without any loss of energy caused by turbulence. The blades’ high efficiency is reflected in power curves taken on all ENERCON wind turbines where power coefficients (Cp) of more than 0.5 are achieved.

Advantages of ENERCON rotor blades:

- Higher efficiency due to modified blade design

- Less noise emission due to optimised blade tips

- Longer service life due to reduced load impact

- Easier transport due to streamlined blade design

ENERCON rotor blades are manufactured with a vacuum infusion process using the so-called sandwich technique. Glass fibre mats placed in the mould are vacuum-impregnated with resin by means of a pump and a hose system. This method eliminates air pockets in the laminate. In order to efficiently protect the rotor blade surface against weather elements such as wind and water, UV radiation, as well as erosion and bending loads, the rotor blades’ protective finish is composed of gel coat, filler, edge protection and top coat using only solvent-free two component polyurethane compounds in the entire system. To efficiently withstand wind loads over the entire usage period, ENERCON rotor blades have an extremely large flange diameter. The double-row bolt connection specially developed by ENERCON for large wind turbines also provides additional strength by creating even load distribution. This is an important factor, particularly in extreme wind locations with considerable stress fluctuations.

Direct Drive

The drive system for ENERCON wind energy converters is based on a simple principle: fewer rotating components reduce mechanical stress while at the same time increasing the equipment’s technical service life. Wind turbine maintenance and service costs are reduced (fewer wearing parts, no gear oil change, etc.) and operating expenses lowered. The rotor hub and annular generator are directly interconnected to form one gearless unit. This rotor unit is then mounted on a fixed axis, the so-called axle pin. Compared to conventional geared systems with a large number of bearing points in a moving drive train, ENERCON’s drive system only requires two slow-moving roller bearings due to its low direct drive speed.

A few years ago only the rotor hub was made of cast steel. However, today, with the use of modern spheroidal graphite cast iron, it is possible to manufacture other major components such as blade adapters, axle pins and main carriers with this process. ENERCON carries out advanced development of its cast components in close collaboration with the foundries. All cast components are drawn with a 3D CAD system and calculated using the finite element method to check for strain increases at critical points. During the entire prototype phase, the designer tests and optimises performance. In order to guarantee the identification and traceability of each cast component when the goods are received at ENERCON, each part is given its own specific barcode from which the serial number can be obtained in the event of quality issues for example. Cast components are only released to the next stages in ENERCON’s manufacturing process once comprehensive quality testing has taken place, thus guaranteeing high ENERCON quality standards in the cast component supply sector. Since mid-2009, ENERCON has had its own exclusive manufacturing possibilities for the cast components of its wind turbines.

ENERCON’s quality testing procedures for cast components:

- Structural inspection on component

- Ultrasonic testing

- X-ray test