Enerpat Group

- Home

- Companies

- Enerpat Group

- Products

- Enerpat - Model AMB-L Series - Lid ...

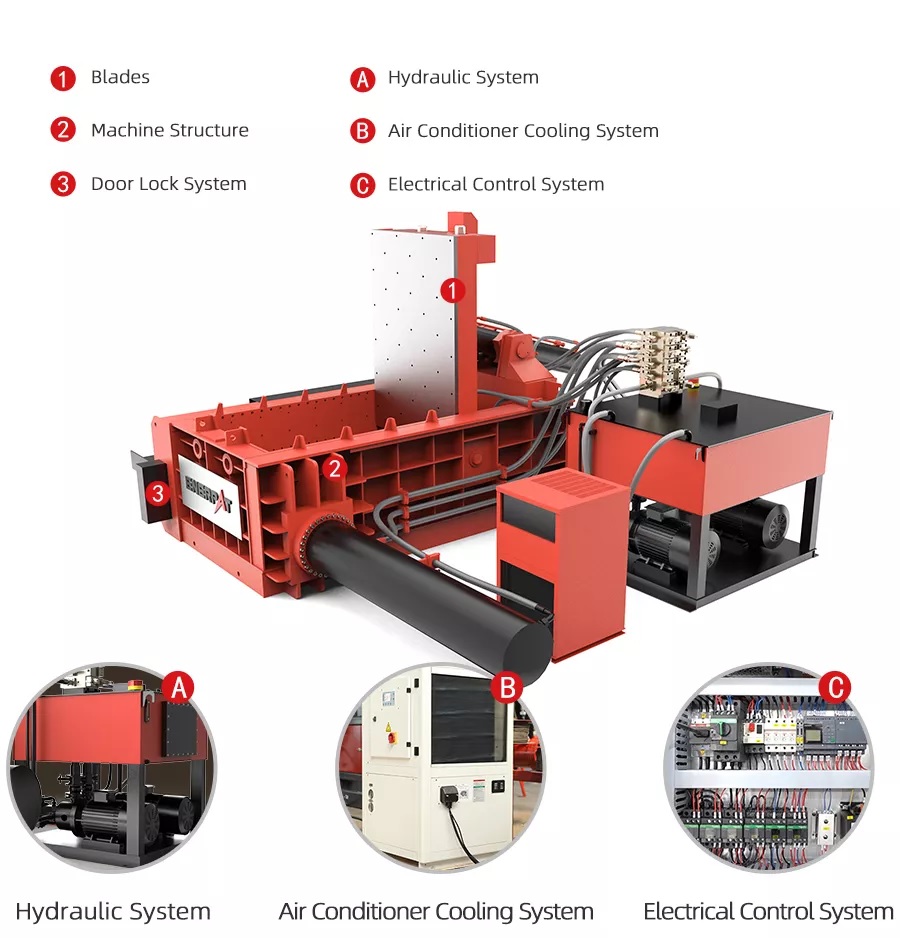

Enerpat - Model AMB-L Series -Lid Style Auto Scrap Metal Baler

FromEnerpat Group

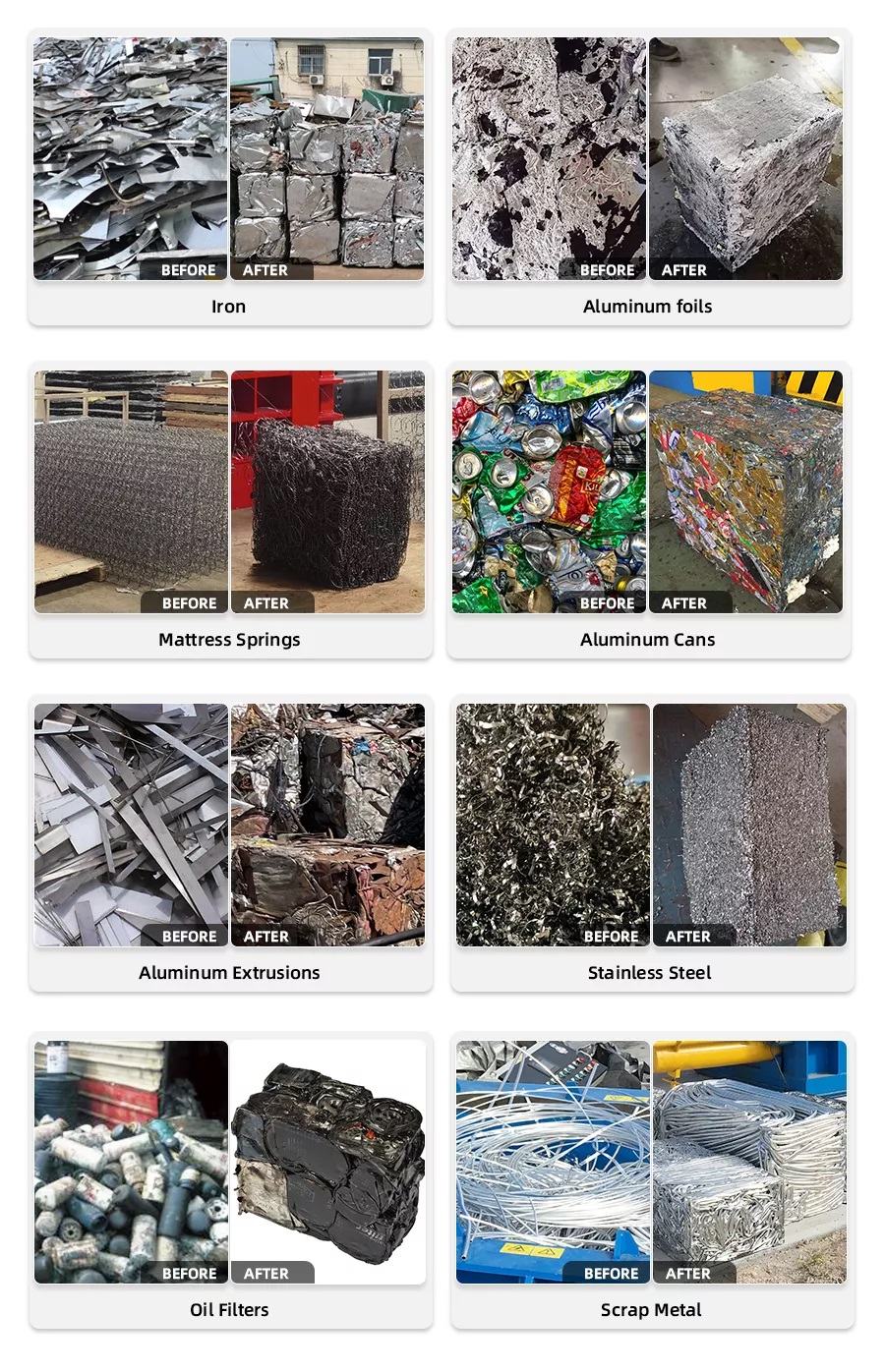

The AMB-L series Metal Baler are widely used in many industries. With ENERPAT Metal Baler, it can help reducing the scrap metals volume, saving the factory space, saving the transportation cost, and more importantly, increasing the furnace efficiency and reducing Smelting cost. ENERPAT Metal Baler press force ranges from 100 tons to 1500 tons, the motor power ranges from 30kw to 300kw.

Most popular related searches

metal baler

air cooling system

scrap metal

air conditioner

cooling system

waste metal baler

scrap metal baler

baler

waste baler

metal waste

ENERPAT Waste Metal Baler designed for pressing bulky waste metals like steel scrap,waste car body,aluminum scrap,etc into compact bales. Reducing the waste metals volume,easy for store and saving cost for transportation. Capacity from 1 tons/h to 20 tons/h. Adopting UK technology,100% high quality with CE,ISO Certification.

- Choose the brand company and international standard Steel Plate

- Using plasma CNC machines to make steel plate for Welding process

- All steel parts are CO2 welded.

- Using the method of flaw detection to detect the quality of welding.

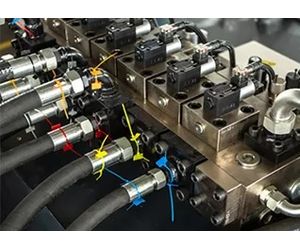

- Choose the brand company and international standard seamless steel pipe

- All piston rods are chrome plated

- Choose the British Hallite brand as the cylinder seal

- Power unit pumps are based on European standard.

- All power units have 90 micron suction filters and 25 micron return filters as standard.

- Pressure filters to 3 microns are optional and give our power units high cleanliness levels.

- Hydraulic power unit suppliers offer a hydraulic circuit and parts list.

- Hydraulic products offer this as well as a full installation and maintenance manual.

- Each power unit is supplied with a test certificate and CE approval documentation.

- An unequalled compacting efficiency

- The baling presses with lid are perfectly versatile machines.

- They are ideal to process bulky and heterogeneous materials.

- Feeding with scrap is very easy as the lid covers the upper part of the compression box

- Air Conditioner Cooling System installed on the hydraulic system

- Air Conditioner Cooling System supports machine 24/7 working

- Air Conditioner Cooling System with Test Certification and CE approved documents

- Factory assembled,wired tested

- Control wiring:minimum2.5

- SQ,nm,600/1000V pvc insulated copper

- conductor colour coded as per IEC standards

- Support touch screen control,PLC Schneider or Siemens brand

- Siemens brand

- Support 24 hours non-stop operation

- Secondary energy consumption motor is more environmentally friendly

- Explosion-proof motor can be installed