- Home

- Companies

- Enerpat Group

- Products

- Enerpat - Model HBA - Fully Automatic ...

Enerpat - Model HBA -Fully Automatic Horizontal Baler

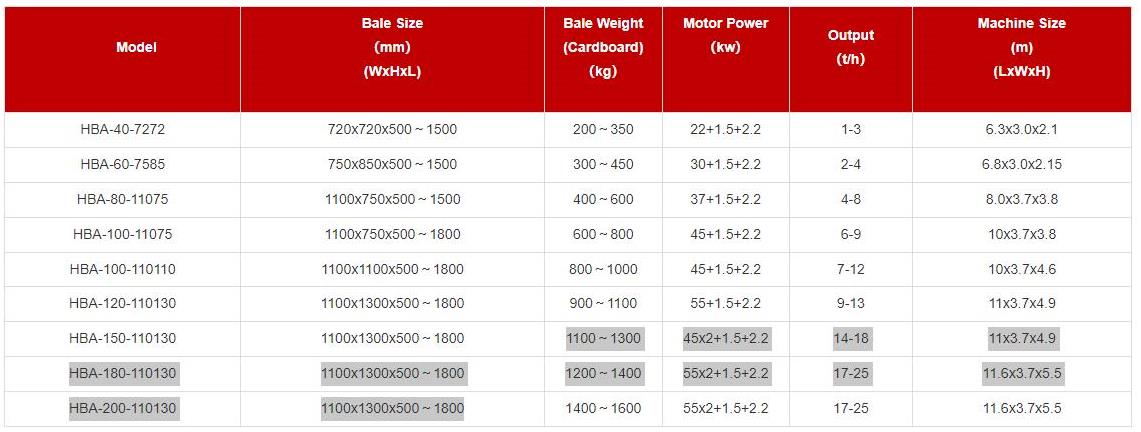

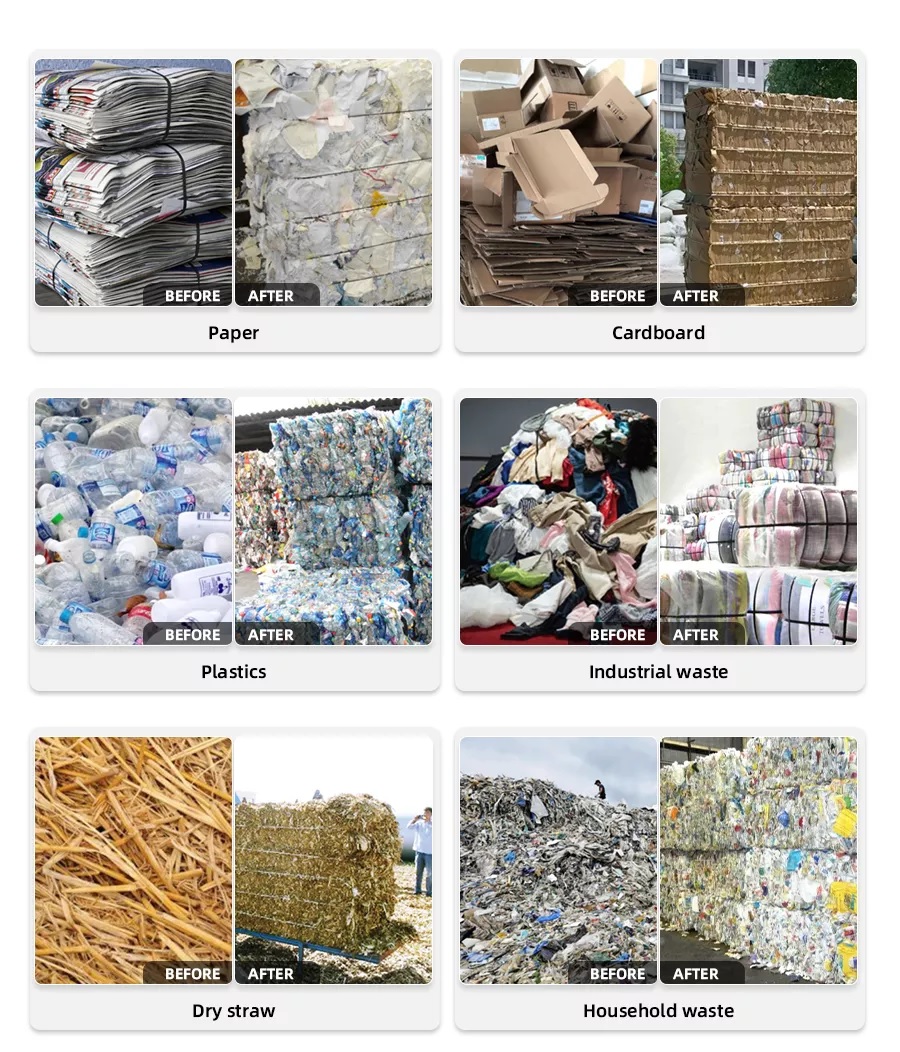

Our fully automatic horizontal balers are an automated version of our horizontal balers, able to process high volumes of recyclable materials such as paper, cardboard and plastics, ideal for companies with a large amount of daily waste to handle. Materials are pressed into stable, high-density bales by our fully automatic balers, which are easy and safe to stack, requiring less storage space. The length and weight of bales is selectable, with bales being tied automatically when the selected length is reached. Our fully automatic horizontal balers are CE marked and designed with customer requirements in mind, making your waste management a simple and cost efficient process.

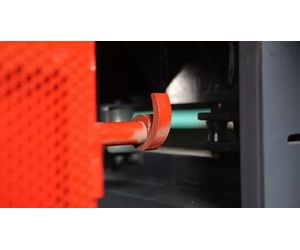

ENERPAT HBA series full-auto horizontal baler are widely used in many industries. It adopts Germany automatic tying technology, high-strength quenched steel wires, making compact bales. 0 complaints and has won high praise from the market.

Enerpat Direct supply a full range of auto tie horizontal balers to handle all the standard materials such as cardboard, soft plastics (shrink-wrap, plastic sheeting), PET bottles as well as hard plastics, aluminium and steel cans and even difficult materials such as RDF (Refuse Derived Fuel).

Fully automatic balers are required when a throughput over 2 tonnes per hour is needed. Tying-off of bales is carried out automatically.

Main applications: industrial waste, domestic waste, cardboard, cartons, waste paper, straw, crushed documents, palm, PET bottles, HDPE bottles, plastic films, woven bags, etc.

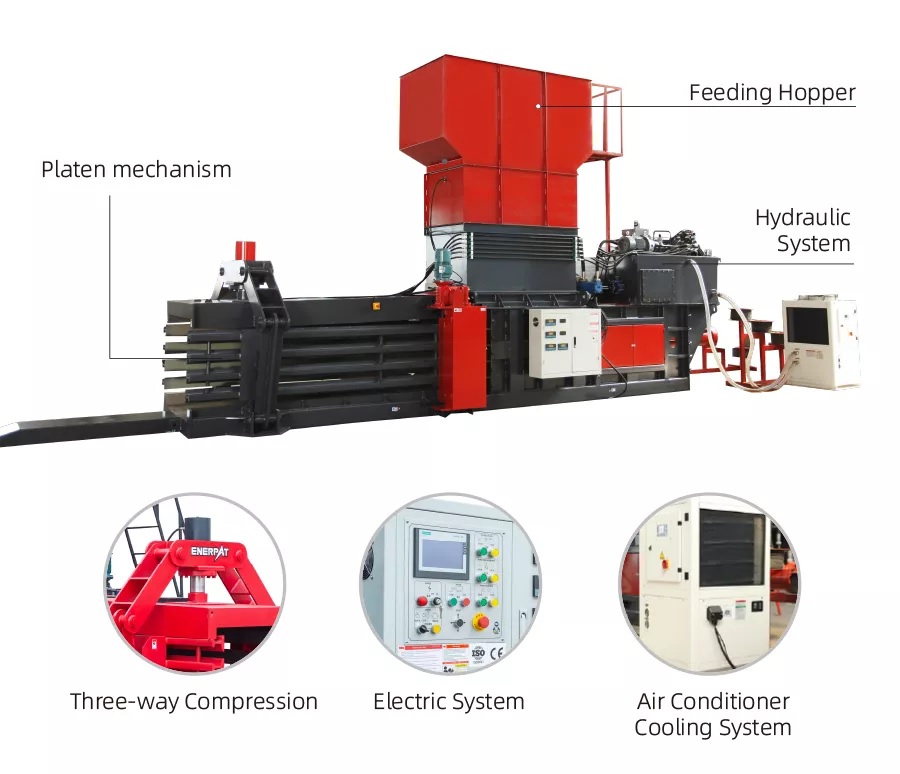

Loading materials on the Conveyor pit,then steel chain feeding conveyor send materials to the baler hopper. Under the combined control of the hydraulic cylinder, three-way compression device, steel wire feeding device, twisting wire device and cutting device,materials been compressed into compact bales,then been pushed out automatic.

- The three-way compression mechanism is equipped with three hydraulic cylinders, which are controlled in two directions and change in linkage with the pressure of the main compression cylinder.

- The three-way compression design ensures that the block is well formed and the finished product has a high density

- Europe Design hydraulic system,efficiency and stable

- International Top Brands valve and pump

- Air Conditioner Cooling System which accept machine 24/7 working

- The main electrical components are selected from the French Schneider brand

- The PLC brand of the equipment is Siemens

- European CE design standard, in line with EU safety requirements

- German automatic strapping technology, stable and efficient

- The core components are imported, reliable and durable