- Home

- Companies

- Enerpat Group

- Products

- Enerpat - Model MSE-H Series - Hammer ...

Enerpat - Model MSE-H Series -Hammer Mill

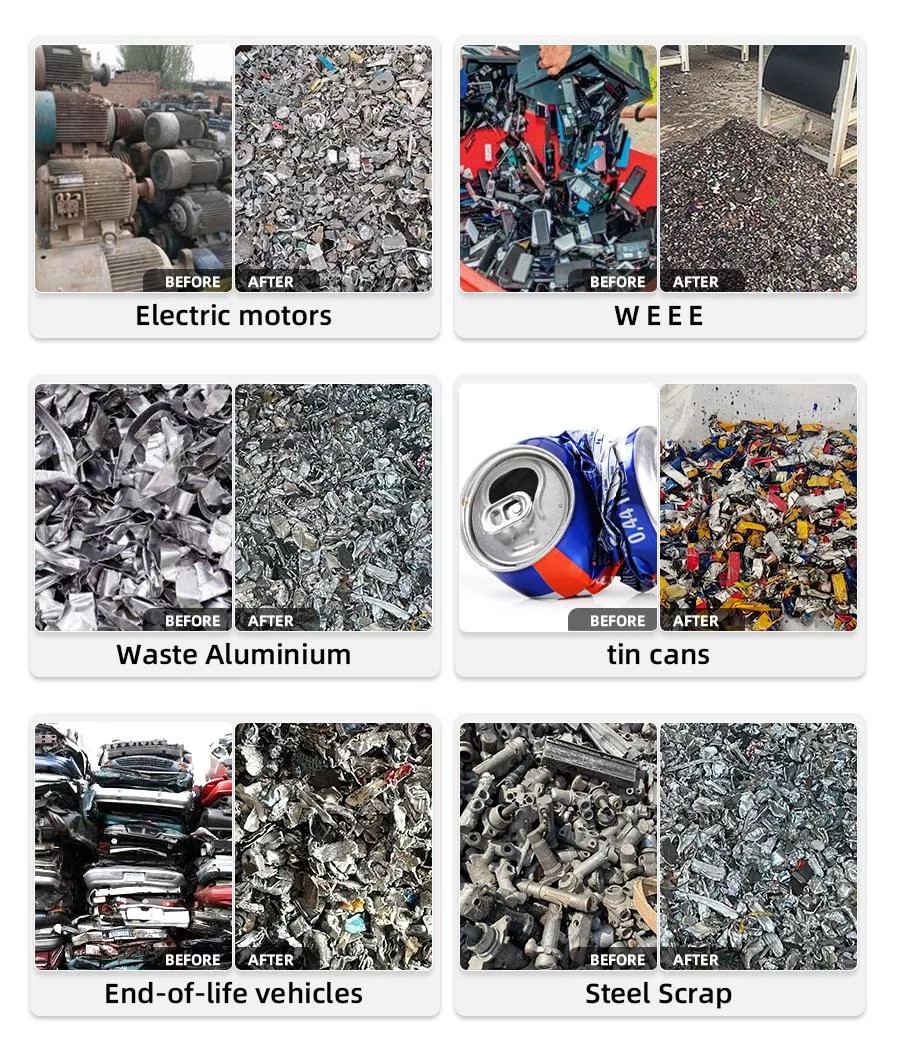

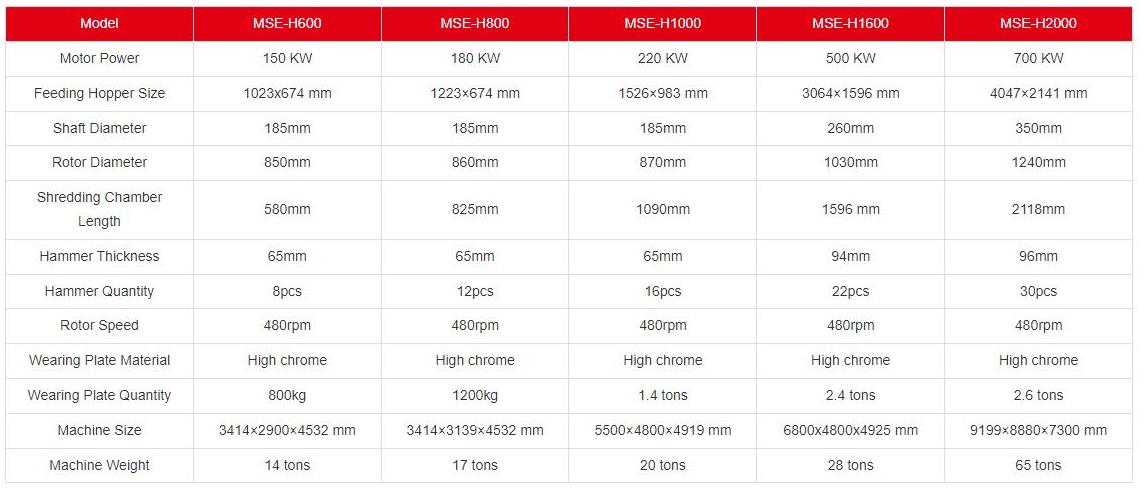

MSA-H series Hammer Mill from Enerpat is for the recycling of scrap metals. It is suitable for processing materials such as car engines, wheels, car shells, motors, steel scrap, aluminum scrap, waste small appliances, aluminum scrap, light scrap steel and other kinds of materials. This machine can be integrated with conveyor and screening equipment to efficiently separate iron, steel, aluminum, and non-metallic materials. It has a capacity from 5 tons/hour to 30 tons/hour. It adopts British technology, 100% high quality and CE, ISO certified.

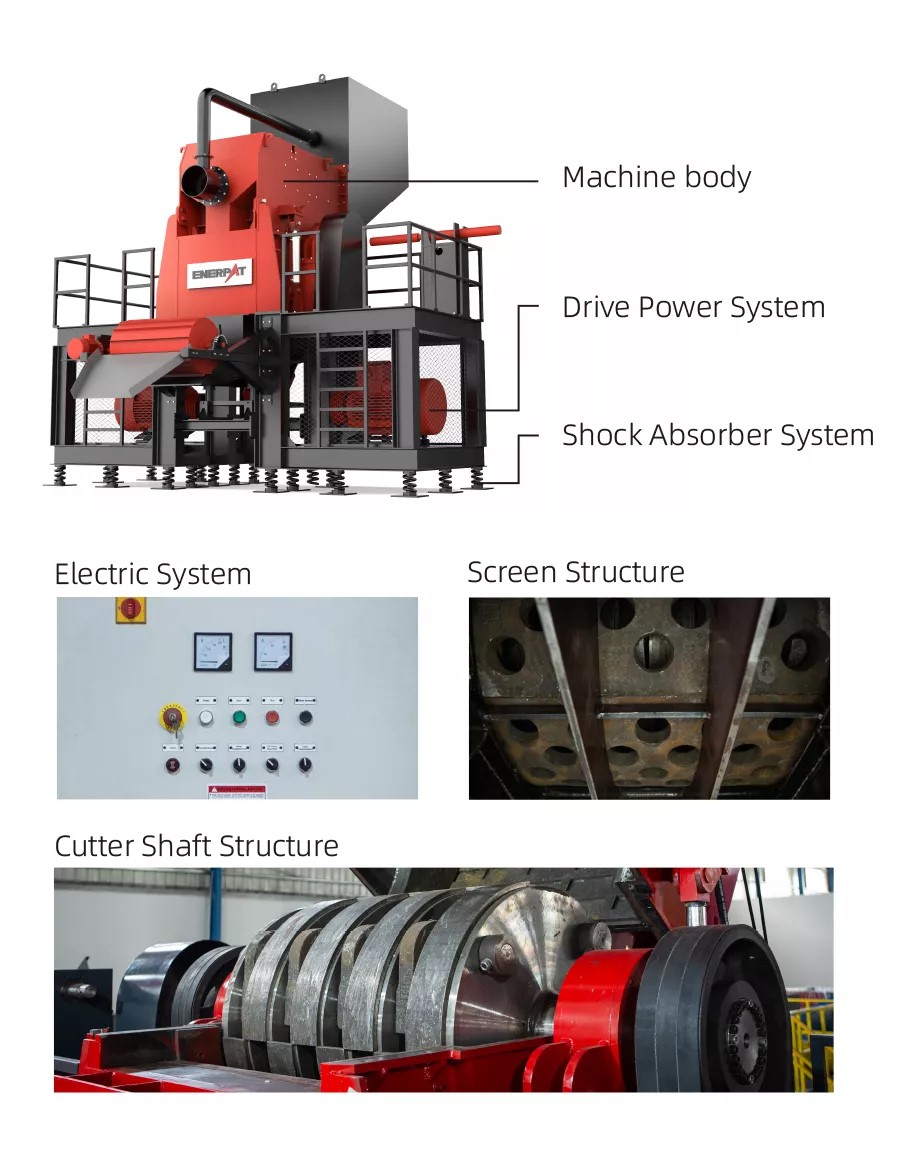

- With HARDOX 500 Wearing Plate on the shaft for protection

- Different hammer design for different materials,which can improve the shredding efficiency greatly

- High chromium steel hammers

- hammers can be rotated 360 degree ,which will not get stuck

- After the crushing chamber is welded, the overall stress relief is annealed, and it is processed and bored by high-precision numerical control to ensure long-term high-load operation of the equipment

- Inside Wearing Plate is NM500 or HARDOX 500

There has sensor inside of the crusher can recognize abnormal material ,It can give instructions to the crusher if meet some hard materials can not crush, to discharge abnormal material automatically

There has rail for the screen,just loose 8 pcs screws,use forklift to pull it, then you can replace the screen. Two minutes is enough .

- We have hydraulic system which can assist us to change the hammers and Pins

- With special Springs installed below the Crusher,it can efficiently reduce the machine vibration when working

- The electric cabinet is equipped with a Siemens/Schneider PLC.

- The electric cabinet boasts a touch screen with a high capability of promoting human-machine interaction.

- Siemens/Schneider electrical components are adopted.

- With SCHNEIDER Soft Starter