- Home

- Companies

- ENTA Treatment Systems Engineering ...

- Products

- ENTA - Cable Operated Bar Screen

ENTA - Cable Operated Bar Screen

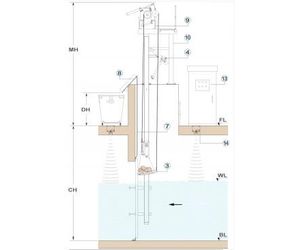

The cable operated bar screen is fully automatic cleaning equipment. It can be used in the inlet channel of pumping station, wastewater treatment plant, power plant and desalination plant for the floating matters screening or bottom accumulation removal.

The rake is traveled in lateral guide rails, by suspension on 3 cables-two for lifting/descending one for opening/closing-the rake can be brought into operation at any depth.

On downward travel, the rake runs in open position within the guide rails. After reached the channel bottom or floating layer the rake movement is reversed by the automatic control of the cable slack sensor ; closed the rake travels upward with the trapped screenings.

Above discharge chute, the screenings are discharged by wiper into a cart or onto belt conveyor. The rest position of the rake is above discharge chute.

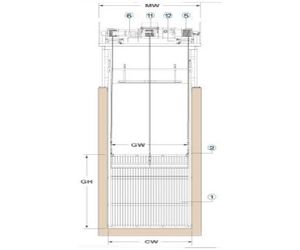

- Screen Grid

- Guide

- Rake

- Wiper

- Cable Drum

- Driving Unit

- Dead Plate

- Chute

- Steel Structure

- Platform

- Rake Pivot Assembly

- Cable Slack Sensor

- Local Control Panel

- Ultra-Sonic Level Sensor (Option)

CH = Channel Depth

DH = Discharge Height

FL = Floor Level

WL= Water Level

BL = Channel Bottom Level

MW = Machine Width

CW = Channel Width

GW= Grid Width

GH = Grid Height

MH = Machine Height