- Home

- Companies

- Entoprot Oy

- Products

- Entoprot - Bioreactor Scalable and ...

Entoprot - Bioreactor Scalable and Automated System

Any alternative protein source must compete against mass-produced poultry or pig meat in human nutrition. In the animal feed market insect protein competes against fish meal and soy protein.

Dr. Entoprot has addressed the process economy challenge by

Using black soldier fly (Hermetia illucens) larvae as the preferred production organism. Production is effective due to the short development time, only 12 days from egg to prepupa.

Designing an insect growing device that can be automated with low cost. This is the first real bioreactor for growing fly (Diptera) larvae.

Entoprot feed Developing low-cost feed mixtures. We focus at consistent quality, good process economy, and high productivity. At present, the feed conversion rate is 30% on dry matter basis and our aim is to improve it further with modern biotechnology. Our aim is to be able to provide the most affordable animal protein in the market, i.e. press the price below fish feed.

What is special in EntoProt Insect Bioreactor Technology?

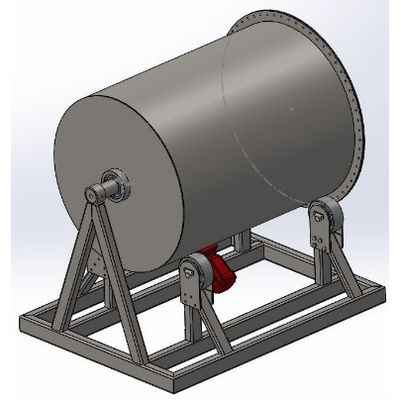

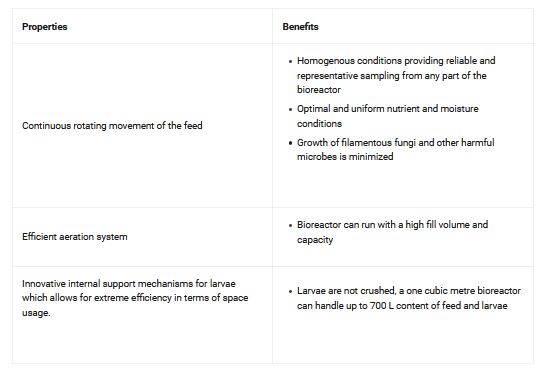

Entoprot focuses on easy handling, low manual work and high yield in their bioreactor setup. EntoProt’s unique patent-pending bioreactor design provides advanced properties, which are not available in any other commercial bioreactor systems.

Bioreactor performance and capacity

The Entoprot technology is genuinely scalable; the number of growing devices can be adjusted to the size of the factory. We have estimated that a 100 m2 plant with a monthly capacity of 9 metric tons of dried larvae requires 30 m2 for bioreactors, 20 m2 for egg-laying adults, and 40-50 m2 space for feed treatment and product processing.

Black soldier fly (Hermetia illucens) is a cosmopolitan. It is spread to all continents into neotropical areas. Though having a wasp-like appearance, BFS is totally harmless. It does not to carry any known diseases, neither does it bite nor sting. Actually, adult flies do not even have a mouth. Adults range from 15 to 20 mm in length, larvae can reach 27 mm in length and 6 mm in width. (Sheppard et al. 2002) . Black soldier fly is abundant in agricultural areas, since it likes to lay eggs into organic waste. The adult black soldier fly is not attracted to human habitats or foods and for that reason it is not considered a nuisance. Besides, it is a lousy flier.

Black soldier fly (Hermetia illucens) adults

Black soldier fly larvae

Life Cycle of BSF

Female BSF lays roughly 500 eggs (1 mm in length) in decaying organic matter. The eggs hatch into larvae in four days. Larvae pass through six instars and require approximately 14 days to complete development (Hall and Gerhardt 2002). The larvae can reach 27 mm in length and 6 mm in width. During larval development, black soldier fly larvae are insatiable feeders. As adults they do not need to feed and rely on the fats stored from the larval stage (Newton et al. 2005).

They eat almost anything, and are robust and mean to the competitors. The digestive tract of BSFL manages many types of feed. Intestinal microbes assist efficiently in decomposition of the feed components. The digestive enzymes, antimicrobial peptides and intestinal microbes gradually spread into the feed in such a way, that it starts to resemble the composition of the larval gut. This leaves poor possibilities for harmful microbes to thrive.

They transform protein-poor feed (organic waste) to valuable proteins.

Cultivation can be easily automated

Cultivation of insect larvae is fairly straightforward. When approaching the pupation age, larvae leave their settings and search for drier locations. Until that point, automation can provide homogeneous and consistent conditions regarding temperature, moisture and nutrient feeding.

They do great job in managing organic waste.

Aside organic waste, BSF larvae can efficiently reduce the amount of manure and decrease its nutrient content. With bovine manure they have been shown to reduce available phosphorus by 61–70 percent and nitrogen by 30–50 percent (Sheppard, Newton and Burtle, 2008). Larvae are able to reduce pollution potential by 50–60 percent or more, and practically remove the bad odour of the organic waste.

Harvested BSF larvae are versatile

- Whole larvae (fresh or desiccated) can be fed to pets, fish and poultry. Dried larvae can be ground to insect meal and fed to fish and pets.

- Larvae milk (pressed larvae devoid of the chitin part) can be further processed to insect meal or protein.

- The oil component can be separated and used for nutrition, as lubricant, for cosmetics, or for bio-diesel preparation

- Even the left-over can be collected and used as a high-value fertilizer.

Rearing insect larvae is an easy-to-handle process with the Entoprot system. The cultivation is done in well-aerated conditions, which guarantees good growth and efficient nutrient usage by the larvae, i.e. good feed conversion rate. Such conditions minimize the growth of odor-producing spoilage bacteria. Cultivation is started with a low amount of liquid feed, which spreads evenly onto the large surface area of the internal support structures (patented) enabling efficient aeration. During the process, more liquid feed is added as the larvae grow.

Stable Self-Sustaining Bioprocess

As insect larvae, microbes and digestive enzymes form a self-sustaining environment, the cultivation process is very stable. Very soon the microbial population in the bioreactor becomes similar to the microbiota of the larvae digestive tract. Additionally, larvae excrete enzymes and bacteria-killing substances such as chitin and antimicrobial peptides into the feed.

Enhanced Feed Utilization by Pre-Processing

To improve the digestibility of the feed and to accelerate the cultivation process, Entoprot has developed a unique pre-processing system.We provide our customers with a proprietary Entoprot Feed Booster microbial composition. The customer adds this to the feed, and after a brief fermentation the feed can be dosed into the bioreactor. New fresh feed batches should be be prepared daily to minimize the contamination risk. Our R&D unit works diligently to optimize the booster compositions for different feed compositions.

Insect Batch Ready in Two Weeks. After Simple and Effortless Cleaning A New Batch Can Be Started

One cultivation, from inoculation to harvest, takes roughly 2 weeks. Starting a new batch is very easy as well. After the larvae have been harvested, cleaning in place can be performed by flushing water through the bioreactor. Due to the aerobic conditions and the presence of a robust microbial population (microbiota), the following cultivation cycle can be started immediately without the need for extensive sanitation.

Feed Preparation and Feeding Made Simple

The feed material is homogenized and suspended in water. With hard-to-digest feedstock (materials with a high content of fibers or lignin) it is advisable to perform a pre-treatment with the Entoprot Feed Booster. The feed can be dosed with an automated peristaltic pump. This provides well balanced conditions regarding moisture and nutrient content. Since the feed is dosed gradually, homeostatis (e.g. regarding pH) can be maintained. This allows the use of a relative high proportion of feed components having non-optimal pH (e.g. waste brewer yeast or silage).

Entoprot has addressed process efficiency and economy by evaluating several feed compositions. Currently we work diligently to provide our customers with suggestions for both (A) high-turnover-feeds giving maximal yield and (B) sustainable feed compositions. Please contact us to get more information about these options.