- Home

- Companies

- ENVITES, spol. s r.o.

- Products

- Envites - Sludge Thickeners

Envites - Sludge Thickeners

Production and installation of sludge thickeners. Our product range consists of sludge thickeners, which are used to effectively reduce the volume of the sludge pumped into the dewatering device (filter press). The main advantages of ENVITES sludge thickeners include high efficiency of thickening and reduction of the amount of the sludge pumped to dewater. Thickeners further prevent the stiffening of the sediment utilizing a slow-speed mixer. At the same time, slow mixing does not break the sedimenting flakes. The simple construction of thickeners guarantees reliable operation with long service life.

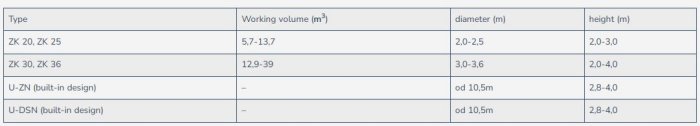

Sludge thickeners are used in the areas of industrial and municipal wastewater purification, for the treatment of industrial and drinking water, and in other applications that require the reduction of the sludge pumped into the filter presses. You can choose from several types of sludge thickeners that differ in working volume.

As standard, we produce sludge thickeners in size ranges with a tank diameter of 2.0-3.6 m and a volume of 5.7-39 m³. At the customer’s request, we are also able to produce sludge thickeners with a larger diameter and volume. The container consists of a cylindrical steel tank with a bottom in the shape of a wide-open cone. The thickener tank is supported by massive legs. On the upper edge of the tank, there is a support bridge for the attachment of a vertical lattice mixer and a stilling cylinder with an inlet pipe. The lattice mixer is driven by a gearbox with an electric engine. The surface treatment is performed as a standard with a multi-component coating.

We will design thickeners with a working volume above 39 m³ individually according to your layout possibilities. Alternatively, we solve a higher working capacity by adding several thickeners next to each other, or by built-in segments in concrete tanks.

Separated sludge from clarifiers, sedimentation tanks, reactors, and other purification or waterworks equipment is introduced through the inlet pipe from above into the central stilling cylinder. Sludge particles fall through the settling space to the bottom of the thickener, while the released sludge water rises against the flow to the overflow trough and is discharged for further purification.

An overflow trough with an adjustable overflow edge is created on the central cylinder or the peripheral shell. In the bottom part of the tank, the vertical grid of the lattice mixer rotates slowly and, by cutting through the sludge, it releases the sludge water to the surface. The arms of the lattice mixer, moving above the bottom, are equipped with a system of inclined blades for moving the sludge to the central part equipped with outlet necks.