Erga Elkron - Model TESS -Triboelectrostatic Separator

Triboelectrostatic drum separator for dry separation of nonconductors with different charge signs.

- Separation/cleaning efficiency up to 99.8%

- Recovery of metal and mineral particle size from 0.040 to 8 mm

- One machine for various mixtures

- High capacity due to enlarged diameter of collecting electrode

- Fine adjustment of separation mode

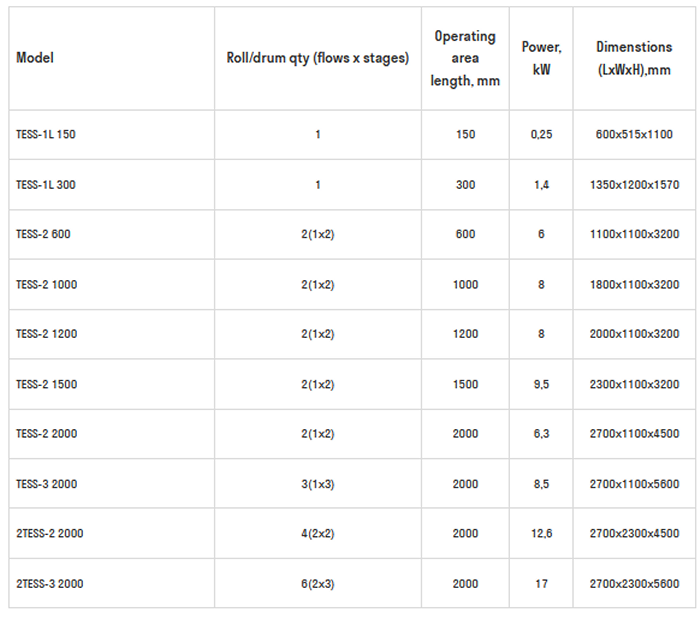

- Low power consumption (from 0.25 kW)

- Touch Screen intuitive control

- Automatic cleaning of electrode

- Reliable components

- Integral automatic protection system

- Dry separation method

ELKRON TESS triboelectrostatic separator provides recovery of the finest metals and mineral particles with size from 0.040 to 8 mm and up to 99.8%. separation and cleaning efficiency of feed material.

Separation/cleaning efficiency up to 99.8%

Required separation mode is selected depending on feed material. Fine adjustment of the collecting electrode rotation frequency, voltage of the deflecting electrode, position of the splitters ensures up to 99.8% efficiency of separation and cleaning of the feed material.

One machine for various mixtures

One TESS machine can separate various mixtures of:

– SECONDARY MATERIALS: PET/PVC, ABS/PS, PVC/PVD, PVC /EPDM, PP / PE, etc.;

– MINERAL RAW MATERIALS: quartz - calcite, garnet-hornblende, quartz - feldspar, nepheline - apatite, vermiculite-quartz), etc.

High capacity

High capacity of ELKRON TESS machine is ensured by the enlarged diameter of collecting electrode (320 mm).

Touch Screen intuitive control

The control panel is a 7-inch high-definition touch screen with user-friendly interface: 3 levels of access to settings (operator, engineer, service specialist). In addition to settings of main operating parameters of the machine, it is possible to save settings of separation parameters for every type of material.

Dry separation method: pure economy!

ELKRON TESS triboelectrostatic drum separator allows for replacement or supplement existing equipment, improving material separation quality with less power consumption and no time and money spent on water and drying**.

** comparing to wet separation method

Automatic cleaning of electrode

Automatic cleaning of collecting electrode allows for downtime elimination.

- rolls

- cleaning brush

- bearing assemblies

- Access to complete information about operation of the machine (operation / idle, operating modes, error decoding, position of magnetic rods, cleaning period)

- Splitter, flap position sensor

- Power supply sensor

- Gas analyzer (ozone sensor)

- Monitoring operation of electric motors (in case of variable speed drive)

- Incoming switch and contactors position control sensor

- Equipment downtime monitoring

- Door status control (open / closed)

- Shock / vibration sensor

- Humidity sensor

- Temperature sensor