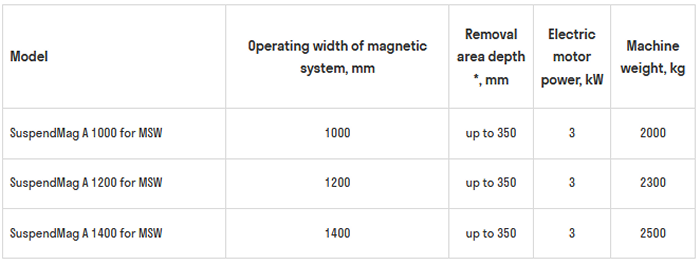

ERGA SuspendMag - Model A -Overbelt Self-Cleaning Magnetic Separator for MSW

Overband self-cleaning magnetic separator for removal of large strongly magnetic inclusions from Municipal Solid Waste flows transported by belt conveyors.

- Increased length of permanent magnetic system

- Efficient throw of magnetic fraction outside conveyor

- Removal area depth up to 350 mm

- Mass of recovered metal up to 30 kg

- Reliable components from the world leaders (Bonfiglioli, Nord, SKF, Asahi)

- 3-ply armored conveyor belt

- Minimum spare parts kit

- Automatic cleaning

- Universal solution for in-line installation

- Option of completing mobile shredders and crushers with suspended magnetic separators with hydraulic motor

Increased length of permanent magnetic system: efficient throw of magnetic fraction outside conveyor

Thanks to increased length of its magnetic system ERGA SuspendMag A for MSW not only extracts especially large metal inclusions weighing up to 30 kg from distance up to 350 mm, but also provides efficient of the magnetic fraction outside conveyor.

Automatic cleaningContinuous cleaning from magnetic impurities is automatic and does not involve any personnel intervention.

Universal solution for in-line installationERGA SuspendMag A for MSW is integrated into existing waste sorting line and does not require any major re-equipment of the site. There are options of longitudinal and transverse installation installation of the separator.

Option of completing mobile shredders and crushers with suspended magnetic separators with hydraulic motorERGA offers service of completing mobile shredders and crushers with SuspendMag A overbelt separators with hydraulic motor for connection to a hydraulic power system. Mounting of the magnetic separator is designed considering the crushing equipment features and Customer’s requirements.

Conformity with industrial safety regulationsThe equipment corresponds to the requirements of industrial safety regulations and rules valid and can be applied at explosive and flammable chemically hazardous enterprises and facilities.

- belt

- bearing assemblies

- Power supply sensor

- Monitoring operation of electric motors (in case of variable speed drive)

- Incoming switch and contactors position control sensor

- Equipment downtime monitoring

- Door status control (open / closed)

- Shock / vibration sensor

- Humidity sensor

- Temperature sensor