Erga WetMag - Model R -Wet Magnetic Drum Separator

Wet permanent magnetic separator for heavy media recovery (magnetite, ferrosilicon).

- Reduction in expenses for dense-medium solids (magnetite, ferrosilicon)

- Permanent magnetic system

- Special design for efficient recovery

- Customized selection of equipment

- Reliable equipment

Self-discharging ERGA WetMag R permanent magnetic drum separator is designed for automatic continuous dense media recovery.

Reduction in expenses for dense-medium solids (magnetite, ferrosilicon)

Special design of the separator, coupled with high magnetic characteristics of the permanent magnet system, provides maximum recovery of magnetite or ferrosilicon from slurry (up to 99.8%).

Permanent magnetic system

Wet drum separator WetMag R successfully replaces EBM type electromagnetic separators without any losses in performance and efficiency of magnetite recovery due to the developed magnetic system (angle 270°) with high-energy permanent magnets. There are no operational costs associated with the maintenance of technically complex electromagnetic system.

For one year of operation WetMag R separator can save about tens of thousand dollars in electricity consumption compared to electromagnetic analogs.

Special design for efficient recovery

Special design of the separator bath provides deep sinking of the drum in the slurry, increasing magnetite recovery zone. This provides higher process efficiency of the separators in comparison with PBM type permanent magnetic separators. The magnetic system has field distribution along the entire drum width without induction gaps and maximum number of poles to ensure stirring and breaking of the floccules, which provides the cleanest concentrate.

Availability of drying scraper instead of the flushing nozzle for magnetic fraction removal ensures getting product with the required solids: liquids ratio.

Customized selection of models

Flexibility of engineering and manufacturing process provides customized solutions for Customer’s required technological parameters (process performance, installation site features).

Heavy media recovery process performance can be increased in WetMag R 2 model by adding the second stage of separation.

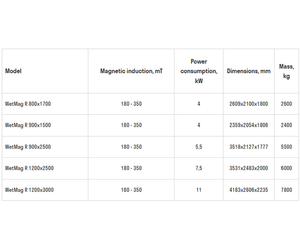

The drum parameters can vary with diameter from 900 to 1500 mm and length from 1000 to 3000 mm.

Protection of operating surfaces

Wear-prone separator parts (bath, drum) are lined with special wear-resistant coatings. Separator covers are made of stainless steel, have increased reliability and wear resistance.

Design of major components is time-proven by heavy duty failure-free operation.

- lining

- bearings