- Home

- Companies

- Energy Specialties International (ESI)

- Products

- ESI - Model CPI - Corrugated Plate ...

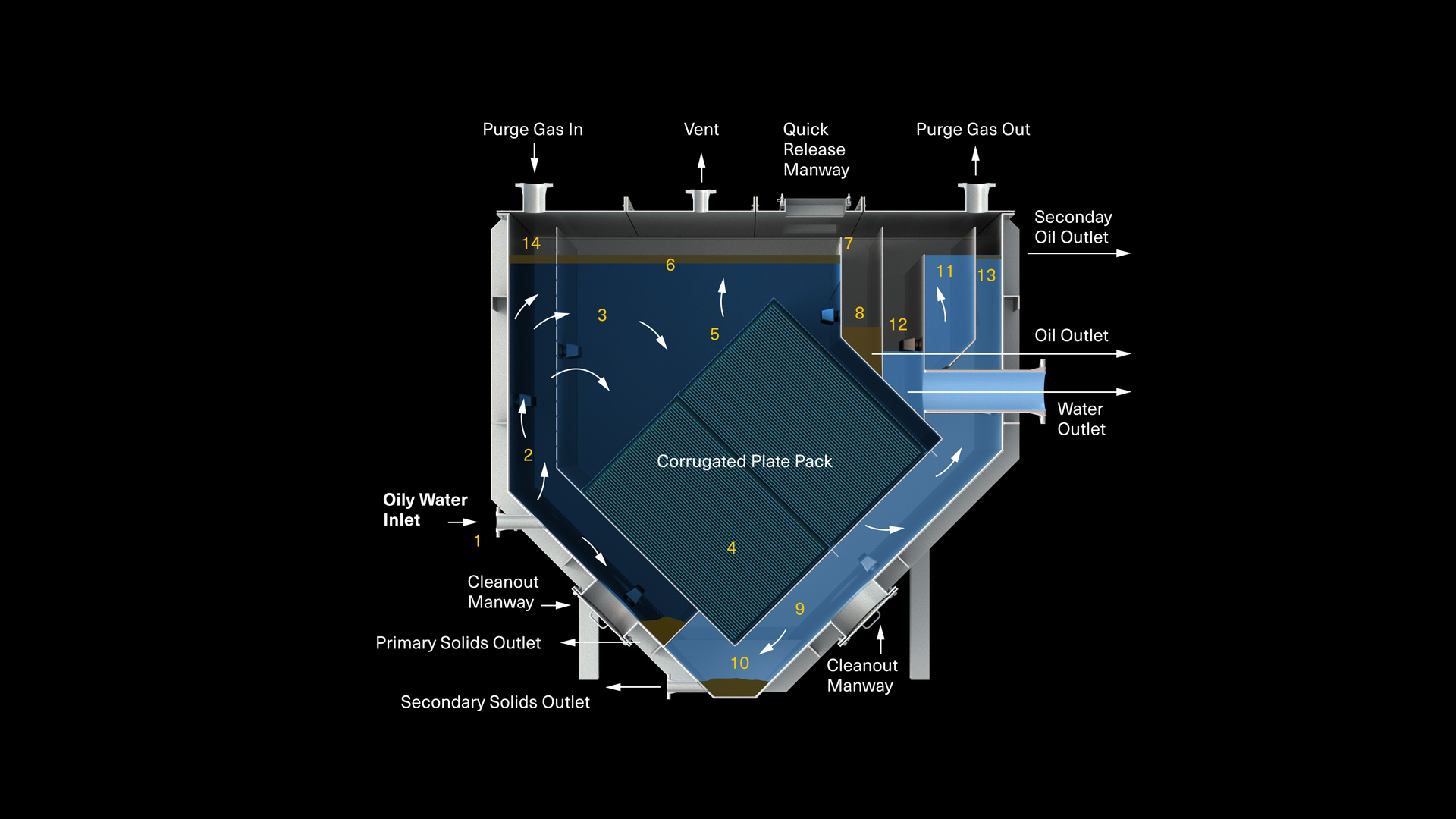

ESI - Model CPI -Corrugated Plate Interceptors

The ESI CPI is designed and engineered for oil recovery applications where energy usage and equipment costs are a determining factor. The CPI is a gravity separator where efficiency is determined by the rising velocity of the smallest particles that will be intercepted, usually greater than 50 microns. The plate pack is made of many closely spaced corrugated plates. Using Stoke’s Law, the rate of rise of the oil can be calculated. The greatest advantage of the ESI CPI is that the rising distance is usually less than one inch. This allows the oil droplets to rise and coalesce to larger droplets or sand to fall out of the flowing stream.

Our eco-friendly CPI recovers oil from water at the lowest cost while using minimal deck space and the least amount of energy.

The ESI CPI is designed and engineered for oil recovery applications where energy usage and equipment costs are a determining factor.

- No Power Requirement

- No Moving Parts

- Compact Design/Minimum Footprint Required

- Low Initial Cost

- Low Operating Cost

- Low Maintenance Cost