ESI - Model EDX-9000E -Benchtop XRF Oil Element Analyzer

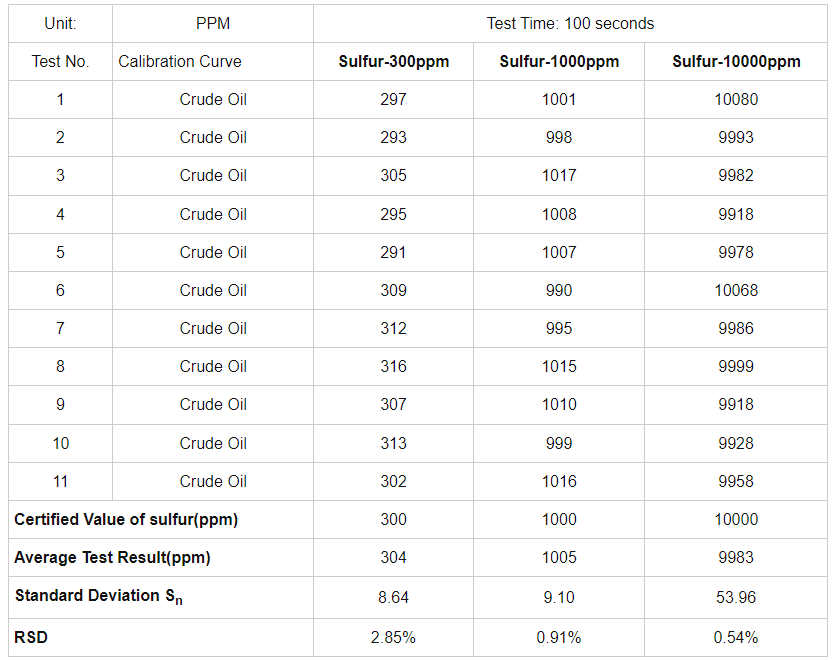

The Sulfur in Oil XRF analyzer Complying with ASTM Method 4294. EDX9000E can be used to test and monitor total sulfur concentration in the production of oils and fuels. Compliant, repeatable and accurate elemental analysis is a given but additional value is generated in several parts in your oil production and refinery. EDX9000E complies with international test methods and regulations, such as ISO 13032, ISO 20847, ISO 8754, ASTM D4294, ASTM D4929, JIS K2541-4, IP 336 and IP 496.

Bench top XRF Oil Element Analyzer- EDX-9000E Simply The Best Advanced sulfur-in-oil analyzer Advanced metals-in-lubricant analyzer Advanced precision Advanced reliability and robustness Advanced software and data management

The advanced performance of EDX9000E can also be extended to the more applications including

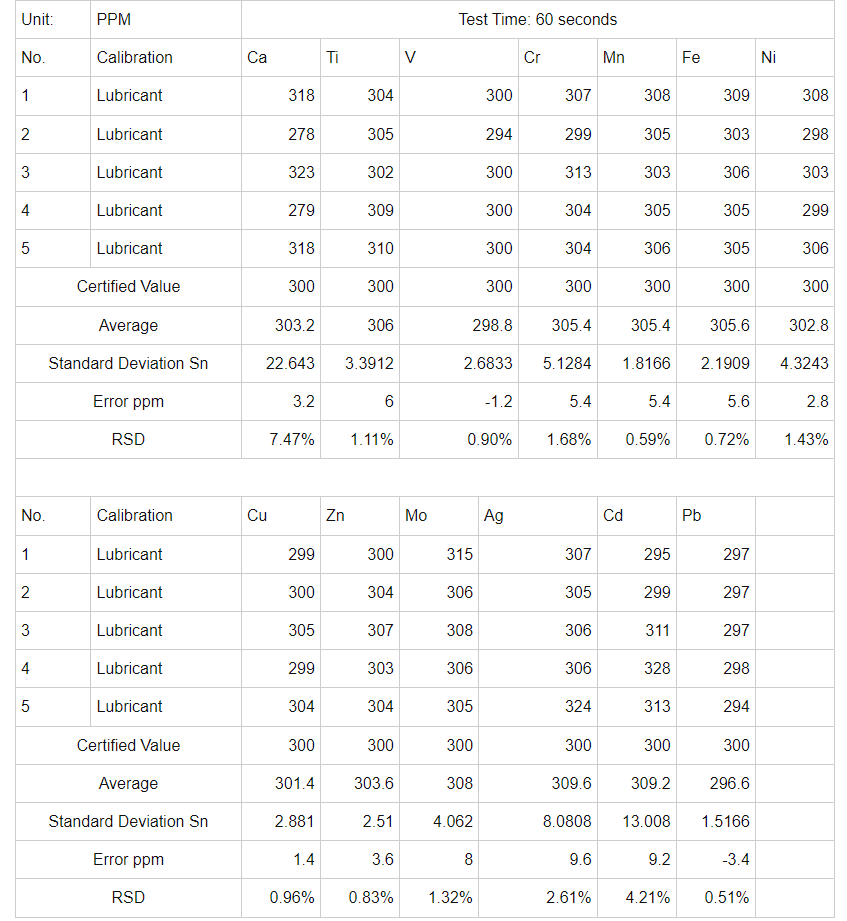

- The wear metals analysis of lubricants to optimize and adapt production processes complied with ASTMD7751/ ASTM D6481/ASTM D5059

- The determination of low levels of chlorine for optimal desalting and corrosion control

- The determination of low levels of S, Ni, V, Ca and Fe to prolong your catalysts` life and improve their performance and the analysis of the sulfur content during fuel production and blending

Simply The Best

- Advanced sulfur-in-oil analyzer

- Advanced metals-in-lubricant analyzer

- Advanced precision

- Advanced reliability and robustness

- Advanced software and data management

- Rugged elemental analyzer for repeatable and reproducible results in laboratories production environments

- Intuitive interface is displayed on the large, industrial touchscreen.

- Streamlined software and one-touch measurement start makes it easy for any operator to get high quality results.

- Training for routine analysis takes only minutes.

- Atmospheric compensation allows analysis without the need for helium or vacuum purge, minimizing the cost per analysis.

- Automatic carbon/hydrogen (C/H) ratio correction allows the analysis of multiple types of oils and fuels to be made on a single calibration, simplifying analyzer setup and operation

- X-ray tube and detector are operated in conditions designed to ensure long-term reliability.

- Built for tough environments.

- On-board data storage of up to 100,000 results, including spectra

- Low cost of maintenance

- Detector: High Resolution SDD

- Excitation Source: 50 watts high efficiency Ag/Rh tube, 50kv Max,1000Max

- Working temperature: -20 to 50 °C

- Measuring time per sample: 30-130 seconds

- Sample Type: Liquid, powders and solids

- Factory Calibration:

- Low sulfur: 10ppm- 100ppm

- High sulfur: 0.01%-5%

- Detection Limit of Sulfur: 3ppm

- Instrument Dimension: 380×372×362mm(L*W*H)

- Weight: 30 kg

- External Connection: USB Port

- Test Report: Excel, PDF

- Spares and Consumables

- Sample test Mylar

- Oil analysis sample cup

- Sampling spoon

- Test window film