Rotavapor® - Model R-220 Pro -Evaporation System

-

Distillation rate: up to 12 L Ethanol/hour

-

Heating bath temperature : up to 180 °C

-

Sample size: max. 12 L per batch

Some of the greatest benefits of the Rotavapor® R-220 Pro, which you, as a user can benefit from, include a user-friendly design with programmable methods guiding through SOPs, automatic distillation even of challenging foaming samples, and remote monitoring on mobile phone with push notifications. Convenient flask handling with patented BUCHI flask coupling and unique flask handler comes on top to further enhance your experience with the industrial rotary evaporator. Finally, plastic coated glassware (P+G) and additional protection shields and grids guarantee your maximum user safety.

The Rotavapor R-220 Pro can be customized to a great extent. You can benefit from four R-220 Pro platforms to match your specific needs: maximum flexibility, highest performance, large volumes or essential demands. Also, seven glass assemblies are available for various uses, including distillation of foaming samples, recrystallization under reflux and height restrictions and any system extensions are easily possible with a wide range of accessories, such as automatic foam detection, temperature monitoring, coolant flow control and many more.

When BUCHI customers say the Rotavapor® R-220 Pro is made to last, they mean it. The R-220 Pro is made of corrosion-free stainless-steel to enhance its durability and prolong its lifetime. The risk of product contamination is non-existent due to the use of highly chemical resistant materials and the robust industrial design ensures seamless 24/7 operation to make your work easier.

Intuitive navigation

The combination of the detachable 8.7" capacitive touchscreen and additional navigation and emergency stop hard keys allow for maximum usability and remote control.

Automatic distillation

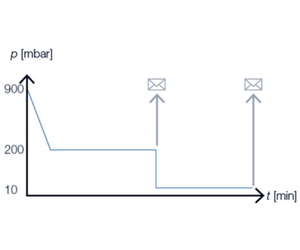

Foaming samples are no longer a problem: The AutoDest function and the foam sensor guarantee for safe and automatic distillation even of challenging samples.

Programmable methods

Customized standard operating procedures (SOPs) provide convenient user guidance through the process and push notifications to mobile phones if attention should be required.

24/7 Operation

The robust design and the use of premium quality materials allow for extensive operation under harsh production conditions and guarantee a for long product lifetime.

At one glance

The user-friendly interface gives a comprehensive overview of settings, current readings and progression graphs of relevant process parameters at any time.

Maximum safety

Safety features include plastic coated glassware (P+G), over-temperature protection, over-pressure release, bath overflow drain, spring-supported valves for glass breakage prevention as well as remote control and monitoring.