- Home

- Companies

- Gasera Ltd

- Products

- Gasera - Model ONE SHED - Evaporative ...

Gasera - Model ONE SHED -Evaporative Emissions Testing Analyzer for Automotive

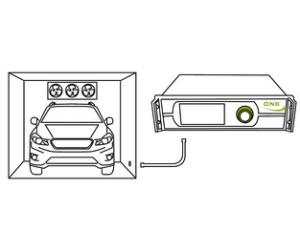

Evaporative losses from the fuel system are tested for vehicle certification. GASERA ONE SHED allows direct monitoring of evaporative emissions as part of the qualification testing procedures for vehicles. The GASERA ONE SHED’s photoacoustic technique is approved by the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB).

GASERA ONE SHED photoacoustic multi-gas analyzer is based on combining ultra sensitive cantilever enhanced photoacoustic detection technology with a widely scanning external cavity quantum cascade laser source operating in Mid-IR fundamental spectral absorption range.

This combination provides an unmatched sensitivity for ppb-level monitoring. Due to the wide scanning range of four gases can be measured selectively and simultaneously.

Evaporative emissions testing for automotive

- Selective simultaneus monitoring of ethanol and methanol

- Sensitivity in the ppb-region for all measured gases

- Highly selective against ambient background gases and other VOC’s

DIRECT MONITORING OF EVAPORATIVE EMISSIONS WITH GASERA ONE SHED

Three testing options with GASERA ONE SHED:

The Sealed Housing for Evaporate Determination (SHED) test monitors evaporative emissions in the automotive industry. Photoacoustic IR spectroscopy (PAS) is used for SHED testing and it is approved by the United States Environmental Protection Agency (EPA) and the California Air Resources Board (CARB).

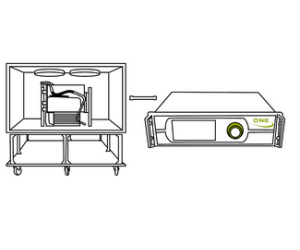

Quantitative leakage testing on mobile A/C equipment for verifying compliance with international standards. The photoacoustic technique provides an accurate and rapid result with a high rate of repeatability, even at very low emission rates, such as those that occur at low to moderate temperatures.

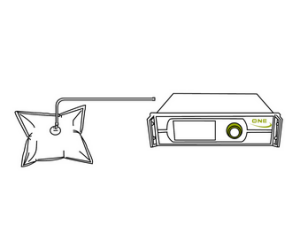

The GASERA ONE SHED can be configured for exhaust gas analysis through bag sampling allowing direct quantitative measurements of trace pollutants in exhaust.

- VOC’s – ethanol and methanol

- Refrigerants – R-134a and HFO-1234yf

- Simultaneous monitoring of ethanol, methanol and refrigerants

- Principle of operation: photoacoustic infrared

spectroscopy - Remote operations with smartphones, tablets

and PC’s - Detection limit: gas dependent, typically in the ppb-region

- Temperature stability: ambient temperature change within the operational temperature range will not cause drift

- Pressure stability: sample gas pressure change within the pressure range will not cause drift

- SHED

- Refrigerant emissions

- Tail pipe testing (CVS sample bag testing)