- Home

- Companies

- FIBERSCOPE.net

- Products

- Fiberscope Proteus - Model ExZ1 - ...

Fiberscope Proteus - Model ExZ1 -Explosion-Proof Pipe Inspection Robot

ATEX Zone 1 Certified Pipe Crawler Designed for Extreme Safety and Precision. Safely conduct infrastructure inspections in potentially explosive atmospheres with the Proteus™ ExZ1 inspection robot. This advanced equipment is designed specifically for Zone 1 hazardous environments, enabling risk mitigation, enhanced clarity, and asset protection through robust and reliable technology. The Proteus™ ExZ1 is an industrial pipe robot that delivers professional-grade quality, reliability, and accuracy, manufactured in accordance with ISO 9001 and ISO 14001 standards. The system features a modular design and a variety of optional components, allowing you to configure a solution that is tailored to meet your specific operational requirements.

The Proteus™ ExZ1 Explosion-proof Pipe Inspection Crawler is an advanced robotic solution engineered specifically for safe and effective inspections in potentially explosive environments. Certified to stringent ATEX Zone 1 standards, this explosion-proof pipe robot ensures intrinsically safe operation, enabling detailed assessments in hazardous locations common to oil and gas, petrochemical, mining, food processing, power generation, and waste management industries.

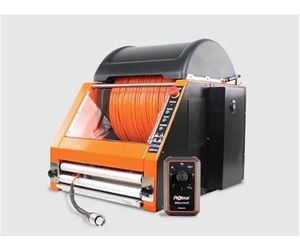

Compact, portable, and ruggedly designed, the Proteus™ ExZ1 system integrates seamlessly into field operations, featuring a robust robotic tractor equipped with a pan-and-tilt camera head, versatile cable reels, and an intuitive control unit.

The tractor is specially constructed for inspecting pipes ranging from 6" to 24" in diameter and can be expanded for larger diameters up to 40" with the optional crawler cradle. Its motorized elevator precisely positions the camera within pipes, ensuring optimal visibility and accurate diagnostics.

At the core of the system, the Proteus™ ExZ1 control unit offers superior operational control through twin ergonomic joysticks and a soft-touch keypad. The 10” XGA sunlight-readable display provides crystal-clear imaging even in challenging outdoor environments. Integrated ProPIPE+ and WinCan software streamline inspection processes by enabling immediate image and video capture, advanced report generation, and seamless data management through WiFi or USB connectivity. A built-in override key switch immediately cuts power upon detection of any ATEX noncompliances, ensuring unmatched operational safety.

Equipped with motorized or manually operated cable reels, including the ACR 500, RAP/RMP 300, and Light System Reel, the Proteus™ ExZ1 offers exceptional cable management solutions. The reels feature Kevlar-reinforced cables of up to 1,640 feet, with mechanisms designed to maintain smooth cable deployment and retrieval under varying conditions.

Two interchangeable explosion-proof camera heads are available, one featuring optical and digital zoom capabilities, continuous 360° rotation, and +/-135° pan, enabling comprehensive inspections. These nitrogen-pressurized camera heads are ATEX Zone 1 certified, waterproof up to 1 bar, suitable for reliable operation in extreme environments, providing precise measurements of pipe diameters, defects, and objects.

Further enhancing versatility, the Proteus™ ExZ1 can be supplied with optional explosion-proof auxiliary lights with integrated backup cameras, carbide and diamond wheels for superior traction, and a nitrogen pressurization kit for compliance with ATEX Zone 1 requirements. An optional portable power pack ensures uninterrupted inspection capabilities in remote locations for up to five hours, significantly improving field productivity.

The Proteus™ ExZ1 Explosion-proof Pipe Inspection Robot exemplifies cutting-edge technology combined with intrinsically safe design, making it an indispensable tool for thorough, efficient, and secure pipe inspections in hazardous, explosion-prone environments.

Note: Proteus™ ExZ1 pipe inspection robot is a specially ordered product. Conditions apply. Call for details.

What qualifies as a “hazardous location”?

Any area where flammable gases, vapours, liquids, dusts, or fibres could mix with air and find an ignition source is deemed hazardous. Typical culprits include gasoline, paint thinners, naturally occurring hydrocarbons, decomposing organic matter, and similar substances. When oxygen, fuel, and an ignition source coexist, fire or explosion is possible.

Our explosion-proof pipe inspection robots are certified for ATEX Zone 1 service (IECEx analogue of Class I, Division 1 in North America, as defined by NFPA 70 / NEC). No pipe-inspection robot on today’s market is rated for ATEX Zone 0 or carries full intrinsic-safety approval, so users must confirm the classification of every work site before deployment.

What does “explosion-proof” actually mean?

Under NFPA 70 (NEC) the term describes an enclosure built to contain an internal ignition and prevent flames, sparks or hot gases from reaching the surrounding atmosphere. It is not designed to survive an external blast; instead, it stops a small internal event from becoming a large external disaster.

Explosion-proof apparatus must also respect the installation`s temperature code - its surface temperature in normal service may never exceed the ignition point of ambient gases or dusts.

North American classification system (Class / Division)

Class I – Flammable gases or vapours may exist.

Class II – Combustible or conductive dust is present.

Class III – Easily ignitable fibres or flyings are present.

CI D1 Hazard is present under normal conditions.

CI D2 Hazard appears only under abnormal or infrequent conditions.

Equipment approved for CI D1 is automatically acceptable in CI D2 areas of the same class, gas group and temperature rating.

International (Zone) classification now adopted by the US & Canada

Zone 0 – Explosive atmosphere continuously or for > 1,000 h/yr.

Zone 1 – Explosive atmosphere likely in normal operation (≈ 10–1,000 h/yr).

Zone 2 – Explosive atmosphere unlikely or only for < 10 h/yr.

ATEX Zone 1, therefore, matches Class I, Division 1 for gas hazards.

Explosion-proof equipment, being the highest gas-hazard category, can always be installed where Division 2 or Zone 2 standards apply, provided the gas group and temperature class match.

Sources for further reference

National Fire Protection Association NFPA / NEC (NFPA 70, ANSI/NFPA 70)

ATEX Directives ATEX Directives 2014/34/EU & 1999/92/EC

Underwriters Laboratories (UL) UL / CSA

Know your site’s classification first; then select equipment, such as the Proteus™ ExZ1 pipe inspection crawler, whose protection concept, gas group, and temperature code fully align with that classification.

Certified to ATEX/IECEx standards - built for crews who can’t afford downtime.

Full compliance for petro-chem, gas and confined-space jobs in highly explosive environments.

Pressurized camera heads with 360º continuous rotation and +/- 135º pan. Optional laser and zoom.

Kevlar-reinforced cable. Manual and Motorized reels with a cable layering mechanism.

- Tractors available to inspect pipelines from 4" to 86".

- Range of wheels, camera raisers and AUX lights.

The Explosion-Proof Pipe Inspection Crawlers Proteus™ ExZ1 are compact, portable units consisting of a robotic tractor with a camera head, a cable reel, and a control unit.

- Certified to Control the Proteus ATEX Zone 1 Pipe Crawler for Potentially Explosive Atmospheres.

- Override Key Switch to Cut off Power Supply If the System Detects ATEX Uncompliant.

- Pre-installed ProPIPE+ and WinCan Software.

- 10” XGA (1024 x 768 pixels) Sunlight Viewable Display.

- Twin Integral Joysticks for Camera and Crawler Control.

- Ergonomic Soft-touch Keypad.

- Adjust the Frequency of the Sonde (33kHz, 512Hz, or 640Hz).

- Footage Reset Key.

- Image/Video Recording, Organizing, and Sharing via WiFi or USB Port.

- Inspection Report Generation with Pipe Graph, Defects, Material, Location & Pipe Size.

- Up to 5 Hrs of Autonomous Work.

- ATEX Zone 1 Certified for Explosive Atmosphere

- For Pipes from 6" to 24" in Diameter

- Motorized Elevator to Center Camera in 8" Pipes

- Speed, Internal Pressure, Inclination, and Temperature Monitoring

- Multi-Frequency Sonde

- Steerable, All-Wheel Drive

- IP68 Waterproof (1 bar)

- Quick Change Wheel Lock

- Articulating ‘Knuckle-type’ Connector

- Optional Crawler Cradle for Pipes up to 40" Diameter

- Optional High-output AUX Lights

- ATEX Zone 1 Explosion Proof Camera Head

- Continuous 360° Rotation and +/-135° Pan

- Accurate Pipe Diameter, Defect, and Object Measurement

- Nitrogen Pressurized for Explosive Environments

- Waterproof up to 1 bar (14.50psi)

ExZ1 CAM026L Pan, Tilt, Laser Camera Head

- ATEX Zone 1 Certified for Hazardous Locations

- Pipe Diameter Measurement Range: 90 - 600mm

- DSP (Digital Signal Processor): Yes

- Aligned Laser Spacing: 25mm

- Camera Sensor: 470 HTVL

- Sensitivity: <1.0 Lux

- Aperture/Field of view: F2.5/75°

- Maximum Illumination Intensity: 12.5k Lux at 150mm

- Pressure Depth Rating: 1 bar (14.50psi)

- Dimensions: 132 x 73 x 73mm

- Weight 1.9 lbs (865g)

- ATEX Zone 1 Explosion Proof Camera Head

- Continuous 360° Rotation and +/-135° Pan

- Optical and Digital Zoom

- Accurate Pipe Diameter, Defect, and Object Measurement

- Nitrogen Pressurized for Explosive Environments

- Waterproof up to 1 bar (14.50psi)

ExZ1 CAM028L Pan, Tilt, Zoom, Laser Camera Head

- ATEX Zone 1 Certified for Hazardous Locations

- Pipe Diameter Measurement Range: 90 - 600mm

- DSP (Digital Signal Processor): Yes

- Aligned Laser Spacing: 30mm

- Camera Sensor: 800 HTVL

- Sensitivity: <1.0 Lux

- Aperture/Field of view: F1.8 - F2.9 / 46° - 4.6°

- Maximum Illumination Intensity: 12.5k Lux at 150mm

- Pressure Depth Rating: 1 bar (14.50psi)

- Dimensions: 155 x 84.5 x 84.5mm

- Weight: 2.53 lbs (1,148g)

Motorized/Manual Reels RAP/RMP 300

- ATEX Zone 1 Crawler Connector Certified for Hazardous Locations.

- Sturdy, Rugged, and Reliable.

- Motorized and Manual Models Available.

- Powder-coated Frame Houses 1,148ft (350m) Kevlar Reinforced Cable.

- Cable Layering Mechanism for Smooth Pay-out and Rewinding.

- Heavy-duty Turning Handle (RMP 300).

- Powerful Three-Phase Motor with an Emergency Stop Button (RAP 300).

- The Reel is Operated Remotely from the Proteus ExZ1 Control Unit (RAP 300).

Manual Cable Reel RMP 300

- Explosion Proof: Kevlar Cable and ATEX Zone 1 Crawler Connector

- Construction: Welded Steel

- Finish: Powder Coated

- Distance Counter Units: Feet, Metres

- Controls: Friction Brake

- Turning Handle: Heavy-duty, Removable

- Cable Layering Mechanism: Tangle-free, Both Directions

- Cable: 6.8mm Kevlar Reinforced

- Cable Length: 1,148ft (350m)

- Cable Weight: 12 lbs per 328ft (5.5kg per 100m)

- Cable strength: 1,102 lbs (500kg)

- Reel Weight: 77 lbs (35kg)

- Dimensions L x W x D (mm): 530 x 400 x 520

- Environmental Protection (Cable Reel): Splash Proof

Motorized Cable Reel RAP 300

- Explosion Proof: Kevlar Cable and ATEX Zone 1 Crawler Connector

- Construction: Welded Steel

- Finish: Powder Coated

- Distance Counter Units: Feet, Metres

- Controls: Dedicated Keys on Control Unit, On-reel Emergency Stop Button

- Motor: Three Phase

- Cable Layering Mechanism: Tangle-free, Both Directions

- Cable: 6.8mm Kevlar Reinforced

- Cable Length: 1,148ft (350m)

- Cable Weight: 12 lbs per 328ft (5.5kg per 100m)

- Cable strength: 1,102 lbs (500kg)

- Reel Weight: 89.3 lbs (40.5 kg)

- Power Supply: 24V

- Dimensions L x W x D (mm): 530 x 440 x 520

- Environmental Protection (Cable Reel): Splash Proof, IP54

- ATEX Zone 1 Crawler Connector Certified for Hazardous Locations.

- For Vans, Pickup Trucks, and UTV Installation.

- Powered Winding in Both Directions.

- Heavy-duty Frame Houses 1,640ft (500m) Kevlar Reinforced Cable.

- Cable Layering Mechanism for Smooth Pay-out and Rewinding.

- Hand-held Bluetooth® Joystick Remote Controller.

- Control Panel Buttons with Dedicated Keys.

- Powerful Three-Phase Motor with an Emergency Stop Button.

- Operated Remotely from the Proteus ExZ1 Control Unit.

- Extendable Van Guide Pulley.

Motorized Cable Reel ACR 500

- Explosion Proof: Kevlar Cable and ATEX Zone 1 Crawler Connector

- Construction: Welded Steel

- Finish: Powder Coated

- Distance Counter Units: Feet, Metres

- Controls: Dedicated Keys on Control Unit, On-reel Emergency Stop Button, RJP Joystick

- Motor: Three Phase

- Cable Layering Mechanism: Tangle-free, Both Directions

- Van Guide Pully: Included

- Cable: 6.5mm Kevlar Reinforced

- Cable Length: 1,640ft (500m)

- Cable Weight: 12 lbs per 328ft (5.5kg per 100m)

- Cable strength: 1,102 lbs (500kg)

- Reel Weight: 121 lbs (55 kg)

- Power Supply: 90 - 264 VAC

- Power Consumption: 600W

- Dimensions L x W x D (mm): 660 x 500 x 652

- Environmental Protection (Cable Reel): Splash Proof, IP54

An explosion-proof pipe crawler is a remote-controlled robotic platform that carries a high-resolution camera, lighting, and optional sensors through pipelines for inspection and survey purposes in hazardous (ATEX Zone 1/ UL CI D1) atmospheres. Its sealed flame-proof (Ex d) or intrinsically safe (Ex i) enclosure contains any internal spark or hot surface, so the robot can operate where flammable gases, vapours, or combustible dusts are present without becoming an ignition source. By keeping inspectors safely outside the hazard zone and eliminating plant shutdowns for manual entry, it delivers fast, detailed visual data while guarding both personnel and production uptime.

Oil and gas

Explosion-proof pipe crawlers inspects flowlines, gathering systems, and crude-export pipes for corrosion, scale, and wax build-up while wells stay online, avoiding the cost of nitrogen purging or hot-work permits in hydrocarbon-rich environments.

Petrochemical & Refining

Navigates complex process and flare headers to verify weld integrity, detect coke or catalyst deposits, and confirm pipe cleanliness during turnarounds, all within areas where benzene, propane, or hydrogen vapours are common.

Power generation

Explosion-proof pipe robots can be employed to traverse fuel-gas, hydrogen-cooling, and condensate-return lines in fossil-fuel, combined-cycle, and nuclear plants, identifying corrosion, pitting, or deposit build-up without interrupting turbine operations or venting explosive gases.

Wastewater & Utilities

Inspects digester-gas, biogas, and sewer force mains where methane and hydrogen sulphide accumulate, helping municipalities detect root intrusion, infiltration, or H2S-induced corrosion without shutting down critical infrastructure.

Food & Beverage Production

Examines starch, sugar, and flour transfer lines—locations prone to combustible dust explosions—without contaminating product or violating hygienic standards, supporting preventive maintenance in bakeries, grain terminals, and distilleries.

Pharmaceutical Manufacturing

Checks stainless-steel process piping and solvent-recovery lines that may contain ethanol, acetone, or isopropanol vapours, ensuring GMP compliance while maintaining the stringent ATEX zoning inside active cleanrooms.

Mining & Mineral Processing

In mining operations, explosion-proof pipe robots can be used to survey slurry, vent-gas, and concentrate pipelines in gold, copper, and coal operations where methane pockets or sulphide dust can create explosive atmospheres, reducing confined-space entries in remote sites..

Waste management

Examines landfill-gas collection headers, anaerobic-digester piping, and solvent-recovery lines in recycling facilities where methane, VOCs, or dust can ignite, supporting safe maintenance and regulatory compliance without halting processing lines.