Kahn & Company, Inc.

- Home

- Companies

- Kahn & Company, Inc.

- Products

- Kahn - Model MPL - External Heater ...

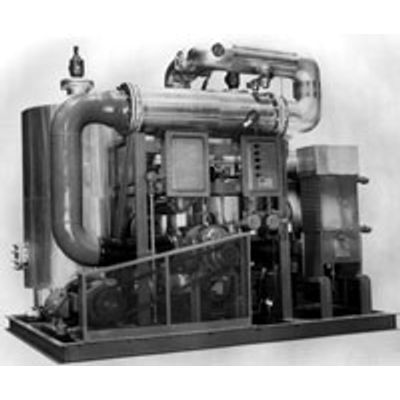

Kahn - Model MPL -External Heater Dryer for Compressed Air and Gas Dryers

The need for clean, pure, moisture-free compressed air and gas is critical. Moisture and contaminants are found in all compressed air and gas systems . . . causing rust and corrosion in your pneumatic tools, contaminating process flows, clogging and damaging delicate pneumatic instrumentation. When lreezing temperatures are encountered, condensation trapped in air systems will freeze, causing cataslrophic failure in pneumatic lines. External heat6r, purge-free, blower type dryers, reflect the stale-of-the-art in compressed air drying - and Kahn is the leader. With I standard models to handle flows from 200 SCFM to beyond 4500 SCFM,4, Kahn offers the best choices in compressed air and gas drying.

Most popular related searches

compressed air

compressed air system

isolation valve

entrainment separator

activated alumina

relief valve

process air

dew point monitoring

condensate trap

compressed air dryer

Standard Features

- No process air or gas is wasted during regeneration.

- All units are completely assembled, pre-piped and prewired on a single common heavy structural steel base using ASME vessels coded for 150 PSIG.

- Heavy-duty reactivation blower for long life.

- Counter flow reactivation for maximum removal of adsorbed moisture.

- Automatic shutoff of heater at "break through" for energy savings.

- Thermal switch cycles heater to maintain desired reactivation temperature.

- Electrically interlocked switching and reactivation valves prevent reactivation until switchover has been executed in proper sequence.

- Controlled depressurization and repressurization reduces bed attrition.

- Stainless steel desiccant support screens in each tower provide uniform flow across desiccant and prevent channelling.

- Towers, reactivation piping and heater unit are insulated for high efficiency and personnel protection.

- Pressure and temperature gages for monitoring operation, and dual relief valves for safety.

- Separate desiccant drain and fill ports on each vessel.

- Long life activated alumina desiccant provides - 40° F pressure dewpoints as standard.

Optional Features

- Pressure dewpoints below - 40° F

- NEMA Class 4, 4X. 7, 12 electrics

- Entrainment separators

- Coalescing prefilters

- Afterfilters

- Manual by-passes

- Dewpoint demand system — Energy saving feature

- Failure to cycle alarm

- Easy to read color change dewpoint indicator with isolation valve

- Solid state dewpoint alarm. Available with meter readout

- Instrument panel

- Steam regeneration heater

- Special designs available for flows up to 10,000 SCFM

- Construction for corrosive environments, explosive process gases

- See data sheet B/C 3141 for more information on accessories.