Fair Mekanik Mühendislik San.Tic.Ltd.

- Home

- Companies

- Fair Mekanik Mühendislik San.Tic.Ltd.

- Products

- Fair - Ecology Unit - Automatic Washing ...

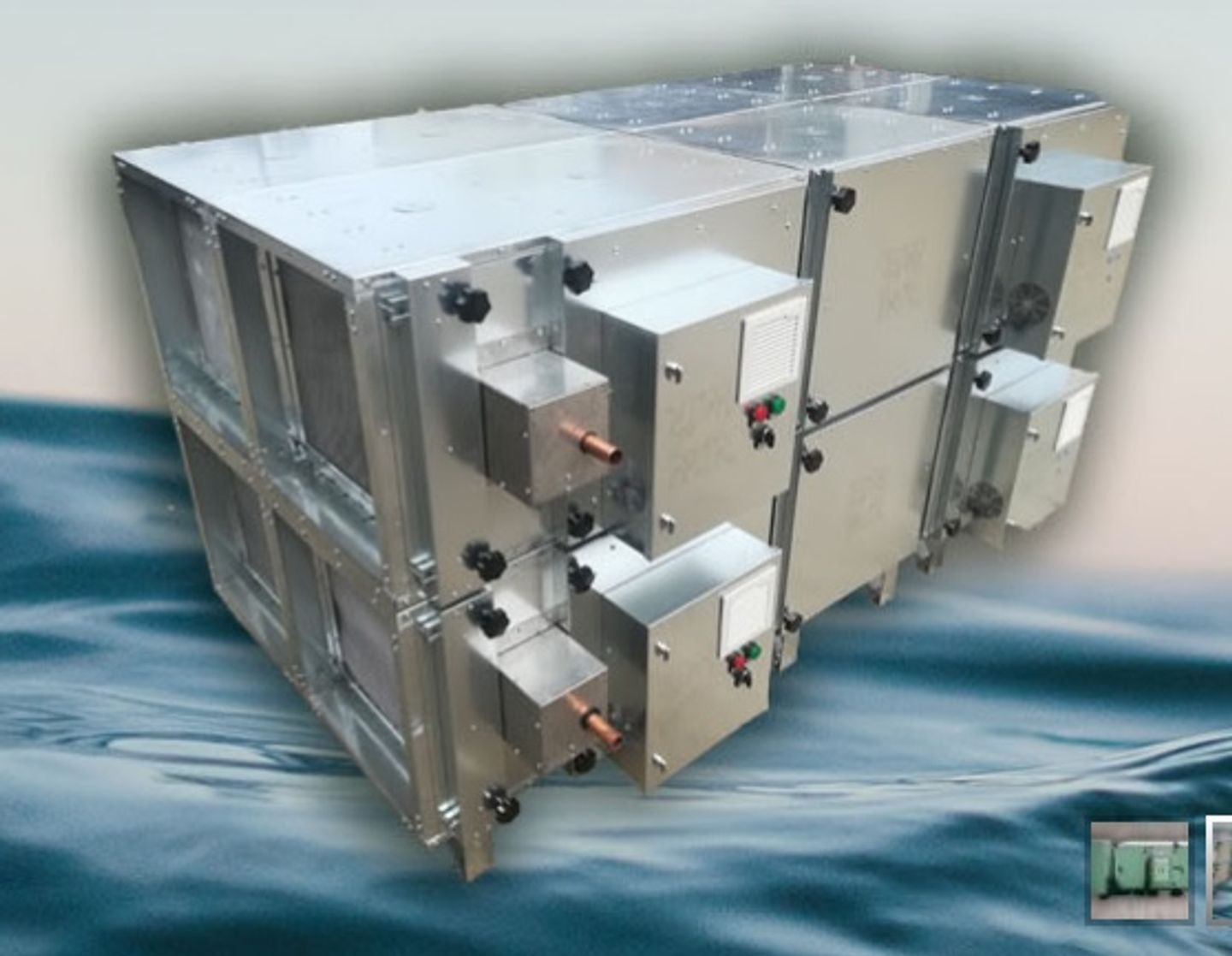

Fair - Ecology Unit - Automatic Washing System

ECOLOGY UNIT AUTOMATIC WASHING SYSTEM is consist of air inlet cell, metal pre-filter, automatic washing system, electrostatic filter, activated carbon filter,( also optional heat recovery coil ) and exhaust fan. In cold climates, since fresh air heating loads are huge, to decrease operating costs and to protect environment, restaurant HVAC systems must be solved by applying heat recovery.

Most popular related searches

automatic washing system

washing system

activated carbon filter

domestic water line

exhaust fan

carbon filter

activated carbon

demand controlled ventilation

domestic water

electrostatic filter

- The unit body shall be composed of double wall panels with 60 mm rock wool insulation and aluminum profiles. Additionally, unit case has Eurovent heat, sound insulation and leakage certificates.

- The unit inlet size is same as the front-face of the ESP. There is an empty cell in order to ensure the uniform air flow at the unit inlet and through the metal prefilter and the ESP. The empty section length is not less than half the section height.

- Pre filter is metal. Metal panel filter is G3 class.

SELF CLEANING ECOLOGY UNIT AUTOMATIC WASHING SYSTEM

- Since the cleaning of the ESP is very important for its efficiency, the unit is equipped with automatic washing system.

- There is automatic washing system between metal pre filter and ESP. The automatic washing system washes both the pre filter and the ESP.

- Automatic washing system is at minimum dimensions suitable for easy installation in a panel of all mechanical and automation equipment. Its dimension is 80 x 120 x 30 cm or less.

- Automatic washing system operates with domestic water line pressure.

- Operates at least 2.5 bar and maximum 8 bar pressure. Operating pressure may be regulated up tu 5 bar.

- The package is ready to use, almost plug and play.

- For the automatic washing system the domestic hot water line is enough to feed the system.

- Automatic washing waste water connection is to a field supplied oil separator.

- The automatic washing system working hours can be adjusted weekly.

- Automatic washing system adjusts both the detergent concentration and the number of washing cycles according to the needs of the user. ( With optional kontrol panel )

ESP CELL

- ESP is selected as cells. Exhaust air flow more than 2,300 m3 / h is not allowed for each cell. ( Cell size 507x444x380 mm. For different flow rates the filter dimensions are calculated proportionally.)

- Exhaust flow rates must be calculated by a mechanical engineer according to the DW / 172 specification, which is also published by MTMD. Exhaust rate calculations must be submitted for approval and stored in a signed form for future references.

- ESP must be installed close to the hood as much as possible. Installation location, duct section, unit connection reducers etc. must be calculated and drawn by a mechanical engineer, and these calculations and drawings must be submitted for approval and stored in a signed form for future refence.

- Ecology unit is modular for the installation of the ESP close to the hood. The other sections ( active carbon filter, the heat recovery and the fan sections ) may also be installed elsewhere.

- The free passage area in the middle section of the ESP cell is least 2.000 cm2. (For 2.500 m3 / h flow rate)

- ESP cell has at least 9 ionizers. Ionizers are in wire structure. (For 2.500 m3 / h flow rate)

- ESP cell has at least 15 m2 collector area. (For 2.500 m3 / h flow rate)

- The ionizers of the ESP cell are loaded with 12 kV and the collectors with 6 kV DC + electricity.

- The power supply has short circuit, arc, over current and thermal protections.

- When the cabin cover is opened, the electricity supply is cut automatically.

- High voltage insulators are made of non-porous polyamide or cestomite. They are not cast porcelain or plastic. Insulators are guaranteed for life time.

- High voltage insulators provide full sealing with the side bearing plates in which they are installed, they prevent the leakage of oil and heat comes with the exhaust air.

- Automatic washing ESP may be made of 304 quality stainless steel ( As an option ). In this option all rods, nuts, etc. elements are made of stainless steel.

- Under prefiltrer, autowash and ESP section there is stainless steel drain pan.

- The ESP has performance test report performed in room conditions. ESP efficiency is 98% and above at a flow rate of 2.300 m3 / h for airborne particulates of 0.5 microns to 10 microns.

- ESP and other filters cannot handle gas-like odors. Therefore, activated carbon filter is used after ESP.

EXHAUST FAN

- Temperature of the exhaust air is controlled by control panel as the efficiency of the ESP and activated carbon filters decreases due to increased temperature and increased humidity.

- Exhaust fan is radial type with sparse blade which is easy to maintain.

- Exhaust fan shall be direct coupled plug type to the motor. Belt driven option is available.

- Ecology unit external static pressure value must be calculated by a mechanical engineer. Automatic fan speed control is very important. Our control panel applies a very flexible demand controlled ventilation scenarios based on exhaust air temperature. Temperature based demand control decreases fan motor consumption upto 57%.

- When the fan cabinet door is opened, the power supply of the fan is cut off automatically.