Anyang Zhenxin Metallurgical Materials Co., Ltd

- Home

- Companies

- Anyang Zhenxin Metallurgical Materials ...

- Products

- Zhenxin - Ferro Silicon

Zhenxin - Ferro Silicon

Ferro silicon from the ZHENXIN ferroalloy factory is a ferrosilicon alloy composed of silicon and iron in a certain proportion and is mainly used for steel smelting and metal magnesium smelting.

Most popular related searches

- Appearance: The appearance of ferro silicon is metallic bread color, without powder and slag.

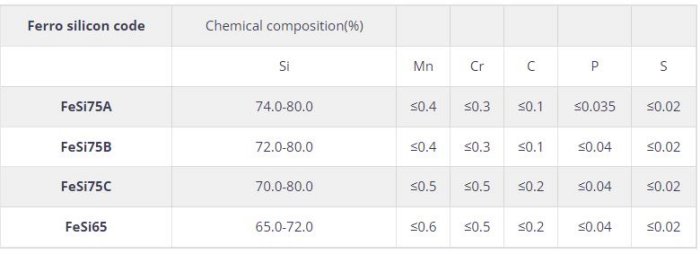

- Chemical composition: In addition to Si and Fe, ferro silicon also includes Mn, Cr, P, S, C and other elements.

- Melting point: 72#-80# ferro silicon melting point 1290?-1360?, 75# ferro silicon melting point 1300?.

- Density: The density of ferro silicon depends on the content of silicon in ferro silicon, and its density decreases with the increase of silicon content in ferro silicon alloy. The density of 75# ferro silicon is 3270kg/m3.

- Deoxidizer: Ferro silicon is used in the steelmaking industry as a precipitation deoxidizer and diffusion deoxidizer.

- Reducing agent: high-silicon ferro silicon or siliceous alloys can be used as reducing agents for the production of low-carbon iron alloys in the ferroalloy industry.

- Alloying agent: Ferro silicon can be used as alloying agent for low-alloy structural steel, composite steel, spring steel, bearing steel, heat-resistant steel and electric silicon steel smelting, to produce single crystal silicon or to prepare non-ferrous metal alloys.

- Inoculant: adding ferro silicon to cast iron can be used as an inoculant for nodular cast iron to prevent the formation of carbides, promote precipitation and spheroidization of graphite, thereby improving the properties of cast iron.

- Coating: Ferro silicon powder can be used as a suspension phase in the beneficiation industry, and can be used as a coating for welding rods in the welding rod manufacturing industry.

The production of ferrosilicon alloy is made by using coke, steel, silica, or quartz as raw materials, heating it to a high temperature of 1500?-1800? in an electric furnace, reducing silicon from silica-containing SiO2, and then dissolving it in molten iron. Among them, metallurgical coke is commonly used as a reducing agent, and iron filings are used as a regulator of ferrosilicon.

Raw materials and power consumption required for ferrosilicon production

- Silica: 1780kg-1850kg

- Coke: 890-930kg

- Iron filings: 220-230kg

- Electrode paste: 45-55kg

- Power consumption: 8400-9000kwh/t