- Home

- Companies

- Cannon Water Technology Inc.

- Products

- FerroKlean - Model Eco-Green Series - ...

FerroKlean - Model Eco-Green Series -Iron Cleaning Treatment Chemicals

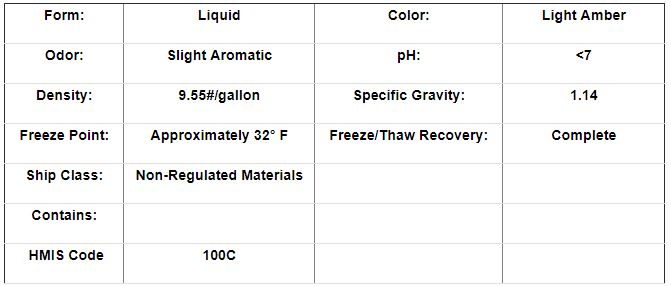

Ferro Klean Iron Cleaning Treatment; Safe Iron Oxide and Rust Removal in Closed Loops, Cooling Towers and Boilers. Safe, non-regulated cleaning agent to remove iron oxide (Rust) by-products from closed and open cooling and heating water systems. Safer to use than aggressive acids such as hydrochloric, sulfuric, phosphoric or sulfamic acid. Contains a corrosion inhibitor that helps protect iron, copper and brass metals during the cleaning process. In addition to removing iron oxide, Ferro Klean will help lift and remove Calcium Carbonate, Sulfate, Phosphate and Organic scale deposits. Utilizes a robust and resilient filming corrosion protector chemical that helps reduce corrosion in multi-metal systems.

Ferro Klean Application Rate and Control Parameters

- For lighter iron oxide deposits, apply Ferro Klean at a concentration of 1%. For example: A 500 gallon system would require 5-gallons of Ferro Klean.

- For medium to heavy deposits, apply a 5% to 50% concentration of Ferro Klean.

- Circulate the Ferro Klean solution for a minimum of 48-hours and check the pH periodically. If the pH increases above 7.5 add more Ferro Klean. After 48-hours flush the cleaning solution to sanitary sewer until the pH of the water equals the pH of the incoming fresh supply water.

- For heavy deposits more retention time may be required to penetrate and disperse the iron oxide deposits.

- Increasing the temperature of the water will increase the effectiveness of Ferro Klean. If possible, increase the cleaning solution temperature to 120 to 190 degrees F.

- Ferro Klean is not aggressive to ferrous and non-ferrous metals; however, removing accumulated deposits may uncover pinhole leaks that were plugged with rust and corrosion by-products. Care should be taken to clean strainers and monitor the circulation of cleaning solution.