Sinta Water Tank Co., Ltd.

- Home

- Companies

- Sinta Water Tank Co., Ltd.

- Products

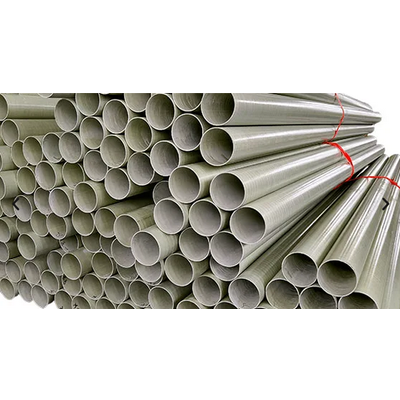

- Sinta - Fiberglass Pipes

Sinta - Fiberglass Pipes

FRP pipes are a new type of composite pipe made from glass fibers, unsaturated polyester resin, and quartz sand filler. Due to their unique material combination and superior performance, these pipes have rapidly developed and been widely promoted in production and application in recent years. GRP pipes are characterized by being lightweight, strong, and corrosion-resistant, making them an important choice for many industries and sectors.