Unicomposite

- Home

- Companies

- Unicomposite

- Products

- Unicomposite - Fiberglass Reinforced ...

Unicomposite - Fiberglass Reinforced Plastic (FRP) Rebar

FromUnicomposite

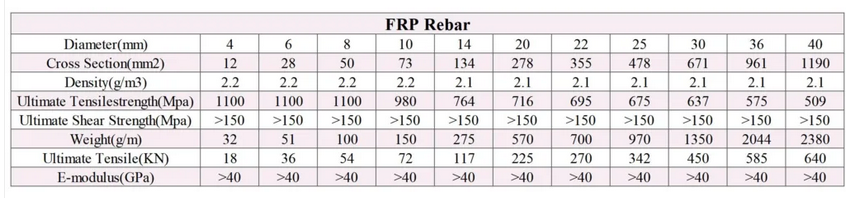

Fiberglass (Fiberglass Reinforced Plastic) rebar is made of high-strength glass fibers along with a highly durable resin. Developed as a superior alternative to steel in concrete reinforcement, FRP Rebar is used to reinforcing concrete in applications where concrete is exposed to water, salt water, or chemical environments.

Most popular related searches

We supply below four kinds of fiberglass rebar

FRP rebar can be roughly divided into four categories according to the material and performance: FRP rebar wrapped in dry yarn, FRP rebar wrapped in wet yarn, FRP rebar with dents, High Load FRP rebar.

- FRP rebar wrapped in dry yarn–Enhance adhesion to concrete, excellent corrosion resistance, higher strength-to-weight and ratdurability.

- FRP rebar wrapped in wet yarn–Provide excellent moisture protection, more suitable for applications with moisture.

- FRP rebar wrapped with dents–High tensile strength, corrosion resistance and durability, surface indentation improves bond strength, stress transfer and adhesion of protective coatings.

- High load rebar–Durability, longevity, and higher structural performance, reducing corrosion-related maintenance costs.

- Non-Corrosive - will not corrode exposed to a wide variety of corrosive elements including chloride ions.

- High Strength-to-Weight Ratio - provides good reinforcement in weight-sensitive applications.

- Non-Conductive - provides excellent electrical and thermal insulation.

- Excellent Fatigue Resistance - performs very well in cyclic loading situations.

- Good Impact Resistance - resists sudden and severe point loading.

- Magnetic Transparency - not affected by electromagnetic fields; excellent for use in MRI and other types of lectronic testing facilities.

- Light Weight - easy to be transported, no need for lifting equipment saving high machine and manual costs.