Sedifilt - Filter Cartridge for Reverse Osmosis Plant

Sedifilt Cartridge for Reverse Osmosis Plants are effective and efficient for removal of silt, sand, rust and other suspended particles from RO feed water.

Test results have shown that Sedifilt filtration technology provides up to twice the dirt holding capacity and filter life at equivalent competitive efficiencies, while reducing pressure drop up to half. All this translates into improved filtration performance and reduced costs.

- Filter Cartridges for , Reverse Osmosis Plants

- Patented media string-wound filter cartridges for effective and efficient removal of impurities such as silt, sand, rust and other suspended particles from RO feed water

- Minimizes fouling and membrane degradation

- Results in improved process economics, reduced operation and maintenance issues

Fouling can seriously reduce performance by lowering productivity and salt rejection, and increasing pressure differential across the system.

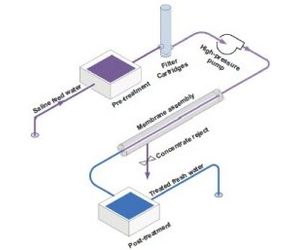

In the reverse osmosis (RO) process, water passes through a semi-permeable membrane, separating dissolved contaminates and giving pure water. This membrane is highly sensitive to fouling or damage from incorrectly treated feed water. To increase the efficiency and life of RO systems, effective pretreatment of the feed water is required.

Pretreatment

Dependent on the characteristics of the raw water, a myriad of pretreatment steps are required to prepare the feed water for the RO process. These include straining, chlorination, coagulation/flocculation, clarifiers, acid addition, pH adjustment, softening, ion exchange, scale inhibitors, multi-media filtration, oxidation, dechlorination, biocidal treatment, activated carbon filtration, UV sterilization, and cartridge filtration.

Fouling is the most significant factor affecting the performance of RO systems. Fouling results from the accumulation of foreign materials from feed water on the membrane surface. Fouling can be from (1) scaling by precipitation and deposition of salts, (2) colloidal or silt fouling from entrapment of particulate or colloidal matter such as bacteria, clay, colloidal silica and iron corrosion products (iron floes), (3) biofouling from the growth of a biofilm from microorganisms such as bacteria, algae, fungi, viruses, and higher organisms, and (4) organic fouling from the adsorption of organic compounds such as humic substance and oil on the membrane surface.

Guidelines for feed water quality

The common indicators of suspended particles used in the RO industry are silt density index and turbidity.

RO system manufacturers recommend final pre-filtration before the pressure pump and membrane with filter cartridges of < 5 micron. Properly selected cartridge filtration as the final safety step has a number of benefits:

- Protects membranes and high pressure pump

- Removes any remaining suspended particles

- Reduces membrane cleaning requirements

- Reduces risk of fouling

- Removes residual flocks and particles after multimedia

- Provides useful information regarding fouling risks and cleaning requirements (by regular inspections of used cartridges)

- Indicates extent of fouling with increase in pressure drop. For example, if the differential pressure across the filter increases rapidly, it is an indication of possible problems in the raw water supply or in the pretreatment process

- Provides short-term protection for the membranes while corrective action is taking place

Sedifilt Filters for Reverse Osmosis plants have proven exceptional performance. A wide chemical compatibility and customization possibilities result in improved economics tailored to the individual application. Sedifilt Filters improve water quality, process efficiency and also provide process protection by removing suspended solids such as dirt, iron particulates and deformable gel type contaminants.

True graded density structure of Sedifilt cartridges ensure higher dirt holding capacity, longer service life, and fewer change outs.

Features

- 100% polypropylene - inert material, excellent micro-organism resistance.

- No chemicals to leach-out with new melt spinning and yarn forming process.

- No media migration because the yarn consists of continuous filaments.

- True graded density - new winding technology gives denser winding in inner layers and coarser winding in outer layers.

- High dirt holding capacity and longer life as particles are trapped throughout the entire cross section of the filter.

- Better performance - multi-lobal cross section filaments with random 3-dimensional media structure captures more particles compared to conventional filters.

- High bulk media having improved void to solid ratio gives higher flow rates with low pressure drop.

- High structural stability, i.e., no shifting of media, excellent knife-edge sealing.

- Structural firmness results in greater resistance to particle unloading and hence more consistent performance.

- Incinerates to trace ash with no hazardous volatiles for environmentally friendly disposal.