- Home

- Companies

- Antares AZV s.r.o

- Products

- Antares - Filter Presses

Antares - Filter Presses

Sludge ending industrial and municipal wastewater treatment plant, production and technological change and drinking water, neutralizing station, processing of raw materials and minerals, chemical industry (production of chemicals),

food industry, pharmaceutical industry.

- processing of raw materials and minerals (oil, sugar, biodiesel, kaolin)

- neutralization station (acid pickling, electroplating, phosphating lines)

- ending industrial wastewater treatment plant sludge,

- ending municipal wastewater treatment plant sludge,

- production and technological change and drinking water

- chemical industry,

- food industry

- pharmaceutical industry,

- clear filtration.

The division

Filter presses are divided by size and type of filter plates, sealing systems and technical solutions and frame filter press equipment.

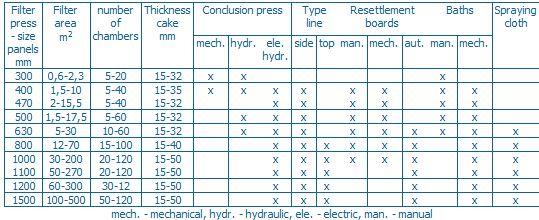

Size of press is characterized by number of filter plates and by the length of their parties, which specifies the size press. We manufacture and supply filter presses with formats boards:

Filter plates creates a workspace filter press - filter chamber. The filter plate is provided inside the chamber profiled surface that allows drainage of the filtrate into the canal and then out of the filter press.

Subdivided filter plates under construction on the frame, a membrane chamber and by the way the filtrate outlet to an open or closed.

Material used for the production of filter plates is in most cases homogeneous polypropylene. The membrane filter plates of the body panels of polypropylene and a membrane may be operational by the nature of media in PP, EPDM, NBR ETC. According to the requirements of technology may be used for plates and membranes used as materials such as PVDF, aluminum, stainless steel, etc.

Mechanical

- clamping force is created by tightening the screw (power whorl)

- size presses 300 and 400

Hydraulic

- clamping force is created by hydraulic hand pump and single-acting hydraulic cylinder with lock nut against loosening filter plates

- press sizes from 300 to 630

Electro

- closure and opening of the filter press provides a electro-hydraulic cylinder unit with automatic shut-off by maintaining pressure

- presses size from 300 to 1500

with side bolsters

- - design with relatively low structural weight, the possibility of manual evacuation of filter plates.

- massive construction particularly suited for large sewage treatment plant and manufacturing operations (kaolin factory, chemicals, neutralizing stations, etc.) in press sizes from 800 to 1500 mm.

division plates

- hand - with the plates is manipulated through handles on their hips,

- pneumatic - especially for larger filter plates (630-1000) can be equipped with a pneumatic press the deportation where one person controls the mechanism for removal of boards.

- automatic - operator only controls the dropout cakes, all the boards together (hydraulic lift war), one plate - gradually.