- Home

- Companies

- ENVITES, spol. s r.o.

- Products

- Envites - Filter Presses

Envites - Filter Presses

Design, production, and sale of filter presses. We are among the leading producers of filter presses for the processing of suspensions. The equipment is used to filter liquids and dewater sludge. The advantage of ENVITES filter presses is high dewatering efficiency, filtrate purity and sludge dry matter. Other advantages include low energy requirements for operation, flexible adaptability to the filtered medium, low consumption of auxiliary chemicals, and the possibility of washing the filter cake.

- High dewatering efficiency

- Low energy requirements

- Great process adaptability

We will design and produce a custom-made ENVITES filter press for you. As needed by the process, we can equip the filter presses with a whole range of additional equipment. After delivery of the device, we will hand over the operating documentation to you and train the operator and the service personnel. We provide warranty as well as post-warranty service and technical assistance.

Filter presses with chamber plates

Filter presses with chamber plates belong to the most used types of pressure presses. The workspace consists of filter chambers made of detachable filter plates. The plates have a recess in the flat part with a drainage system. The total recess depth of both adjacent plates determines the thickness of the resulting filter cake, which ranges from 10 to 50 mm. The working pressure is up to 16 bar for the standard design and up to 30 bar for the special design.

Filter presses with membrane plates

Filter presses with membrane plates use a workspace with filter plates with a movable membrane. The membrane serves to compress and squeeze out the filtered cake. As a result, a higher dry matter content in the filter cake is achieved than in the case of a filter press with chamber plates.

Customer solution

We will propose the most suitable structural design according to the needs of the technology and the customer’s requirements.

- Design for an environment with the risk of explosion of gases and vapors

- Installation in a container

- Special frame treatment

- One-stroke filter press

- Special covering and sheathing

We produce ENVITES filter presses with open and closed filtrate discharge and with the possibility of manual or automatic closing and separation of the filter plates. We produce filter presses with a side bolt and with the upper suspension of the plates.

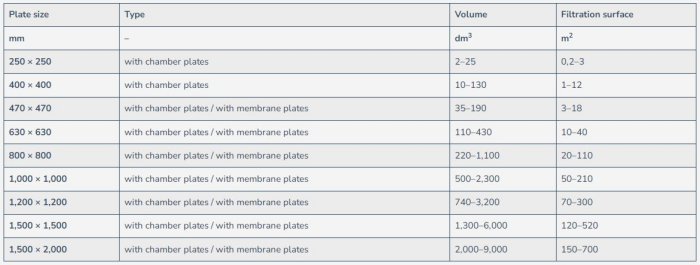

- Filtration plate size: up to 1,500 × 2,000 mm

- Volume of the filter press chambers: up to 9,000 dm³

- Filtration surface: up to 700 m²

- Thickness of a filtration chamber: from 10 to 50 mm

- Filtration pressure: The standard pressure is 16 bar, we also produce filter presses for filter pressures up to 30 bar.

- The achieved dry matter of the filter cake: according to the process up to 95 %