Henan Lane Heavy Industry Machinery Technology Co., Ltd.

- Home

- Companies

- Henan Lane Heavy Industry Machinery ...

- Products

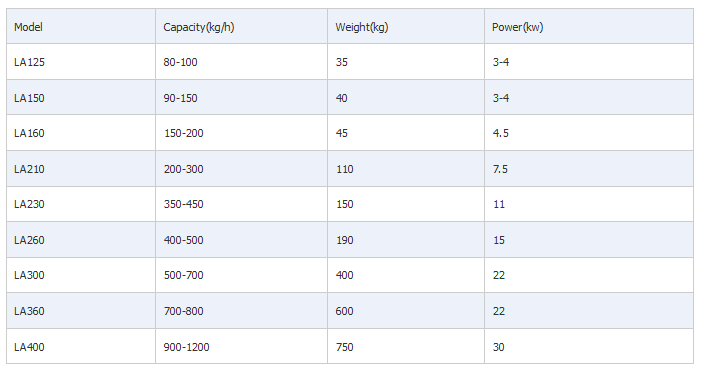

- Lane - Model LA - Flat Die Granulator

Lane - Model LA -Flat Die Granulator

Flat die granulator is a kind of commonly used granulation equipment, mainly used for powder or granular materials for granulation processing, the loose powder materials through the action of pressure and friction into a certain shape and size of the particles- Commonly used in fertilizer production line, feed production line and cat litter production line, etc.

Most popular related searches

The raw materials used by flat die granulator in fertilizer, feed and cat litter production line are as follows:

- Fertilizer production line: urea, diammonium hydrogen phosphate, ammonium sulfate, ammonium nitrate, calcium

- superphosphate, potassium sulfate, potassium magnesium sulfate, potassium chloride, magnesium sulfate, and so on.

- Feed production line: corn, soybean meal, fish meal, bone meal, protein powder, bran, starch, bagasse, wood chips,

- rice husk, wheat bran and so on.

- Cat litter production line: natural bentonite, corn cores, wood chips, bamboo chips, silica gel, quartz sand, paper

- shavings, rice husk and so on.

- Different types of fertilizer, feed and cat litter production line focus on different, the use of raw materials are also

- different, in the actual production, but also need to choose the appropriate raw materials according to the specific

- production process and product requirements.

Composition structure of flat die granulator:

- The flat die granulator is mainly composed of feeding system, pressing system, regulating system, transmission system

- and discharge system.

- Among them, the feeding system includes feeder and feed opening;

- The pressing system includes mold rollers and pressing chamber;

- The regulating system includes a regulating device and a control panel; the transmission system includes a motor, a

- reducer and a transmission device;

- Discharge system includes particle discharge outlet and discharge device.

- The working principle of flat die granulator is to press the material into granules by mechanical pressure.

- The material is firstly fed into the pressing chamber by the feeder, and then pressed by two parallel die rollers. During the pressing process, the die rolls rotate and the material is squeezed between the two rolls, after a certain pressure and shear force, the material gradually forms granules. Finally, the finished pellets are discharged through the outlet.