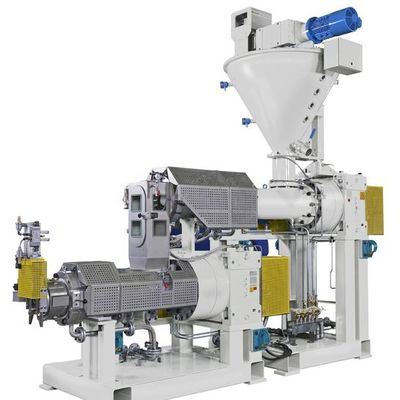

Fleming - Planetary Roller Extruders

BCtouch Control:

- Supports OPC-UA Protocol

- Supports industry 4.0 functions

- Control mounted directly on the extruder cabinet or on a mobile stand

- Individually customisable user interface: adapted to every machine operator (language, icons, screen configuration)

- Up to 7 extruders can be integrated into the control

Planetary Roller Extruders Advantages:

- Excellent controllability of melt temperature

- Self-cleaning system

- Narrow, controlled range of residence time

- Balanced ratio of shearing and heat transfer

- Short formula change-over times, because the toothed components continually interlock so that no material deposits can form

Product Features:

- Single-stage and two-stage planetary roller extruders in the sizes 140, 170, 200, 250 and 350/355 mm

- Outputs of 450 – 4,000 kg/h (PVC), 400 – 2,200 (ABS) and 500 – 2,200 kg/h (EVA)

- Adjustment to different formulas possible

- Flexible design

- Thin PVC sheet

- Pellitising

- 12 Month Warranty

- Spare Parts Support

- Energy Efficient Analysis

- 24/7 – 365 day Service Support

- Preventative Maintenance Scheme

Any successful project begins with a well-designed project scope that demonstrates understanding of the task ahead. We know projects are won during this preliminary stage and work very hard to ensure our clients are confident their scope is understood.

Fleming’s in-house design engineers can partner with you to design a modular solution tailored to your business, ensuring it meets current and future manufacturing needs. We understand customers appreciate transparency with advice and quotations, or that if machinery operation fails, so does productivity. Fleming’s experience and understanding of manufacturing, coupled with quality product, is a good place to start in reducing the possibility against failure.

Fleming provides a full solution recommendation complete with detailed CAD drawings and factory scale layouts. The attention to detail and accuracy our design team implements into our drawings calculates exact quantities of installation components bringing our projects in on budget without hidden cost or excess leftovers.

A Fleming project manager will be assigned to co-ordinate the entire installation time-line from delivery onsite to final handover to minimise down time and interruption to your daily business.

Fleming’s service installation teams will ensure ongoing post-installation support and maintenance.

It is Fleming’s recommendation that customers consider an (optional) Preventative Maintenance Scheme to reduce the possibility against future failure. Preventative Maintenance is delivered by one of Fleming’s trained service technicians.

Spare Parts: We know how important the speed of repair should be. If spare parts are required at any point in the life of the equipment, Fleming can either arrange same-day despatch (on orders before 12 noon) on quality replacement parts, or, arrange immediate order and delivery within 7 working days if coming from overseas. Our financial investment to carry strong hold of all main spare parts locally is backed with an automatic re-ordering schedule.

Service: 24 hour/365 Days a Year – Fleming provides a 24 hour call out service all year round. Our national team of experienced technicians are passionate about plastics, chillers and conveyors, and will attend to the issue in the shortest time possible. Please call Fleming between 8am to 5pm (excluding public holidays):