Primus Line - Flexible Above-Ground Pipes

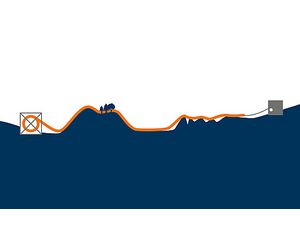

The Primus Line® Overland Piping system is an environmentally orientated, quick to install and reusable solution for creating above-ground pipes. It can be flexibly unrolled and rolled up again and adapts naturally to changes in direction and uneven surfaces. Its installation is also possible in challenging and hard-to-reach terrain. Numerous liquid media can be transported, including demanding and potentially hazardous media. Reusable solution for the above-ground transport of demanding media.

Safety

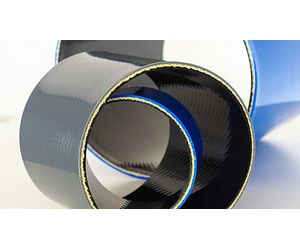

- Core made of seamlessly wovend Kevlar® fabric

- The burst pressure of the flexible pipe is at least 2.5 times higher than the allowable operating pressure

- No hot works – welding or butt fusion welding – or work with hazardous material on site

- Continuously monitored production process

Cost advantage

- Completely reusable

- Small storage requirements

- Transport of up to four kilometres on one single transport spool/lorry

- Minimal mobilisation and demobilisation costs, reduced manpower

- Easy unrolling and rolling up

Efficiency

- 1,000 metres and more available as one continuous length

- Limited connection points = less weak points

- Fast installation - up to 12 times faster compared to HDPE

- Laying up to six kilometres per day

- Flexible – adapts naturally to the surface

- Lightweight: 2.5 to 6.1 kilograms per metre

Environmentally orientated

- Waste reduction due to reusability

- No heavy equipment

- Eliminating CO2 emissions by heavy lorries during operation for the transport of liquids

- Installation in sensitive environments like nature reserves or bodies of water is possible with minimal environmental impact

- We also pay attention to sustainability as a company

One main benefit of Primus Line® Overland Piping is its simple, fast and safe installation that requires only few tools, welding work or after-treatment of the liner. This also enables an installation with only little environmental impact in sensitive environments like nature parks or waters. After use, the system is just cleaned and rolled up. It is now ready for its next use.

To complete the (un-)installation, just a few steps are necessary:

Installation

- Installing the hauling rope

- Laying the liner

- Mounting the connectors

- Pressure test

- Connecting the line

Uninstallation

- Decommissioning the pipeline

- Disassembling the connectors

- Installing the hauling rope

- Winding up the liner

Primus Line® offers you an efficient and environmentally orientated alternative.

Hard-density polyethylene pipes (HDPE pipes) are often the first choice for installing above-ground pipelines. For a comparison of the properties of HDPE pipes and our innovative Primus Line® Overland Piping system and the requirements for constructing 6 kilometres of pipeline, please refer to our website.

Nominal widths

DN 150 to DN 350

Wall thickness

6 millimetres

Laying in curves

Possible

Maximum operating pressure

Up to 56 bar (depending on the diameter)

Temperature resistance

More than 30 degrees Celsius (up to 60 degrees Celsius under certain conditions)

Friction coefficient

k = 0.028 millimetres

Installation length

1,000 metres and more in one section

Media resistance

Suitable for numerous liquid media