- Home

- Companies

- HS-Group GmbH

- Products

- HS-GROUP - Model NOVAWEB Series - ...

HS-GROUP - Model NOVAWEB Series -Flexible Web Coating Platform

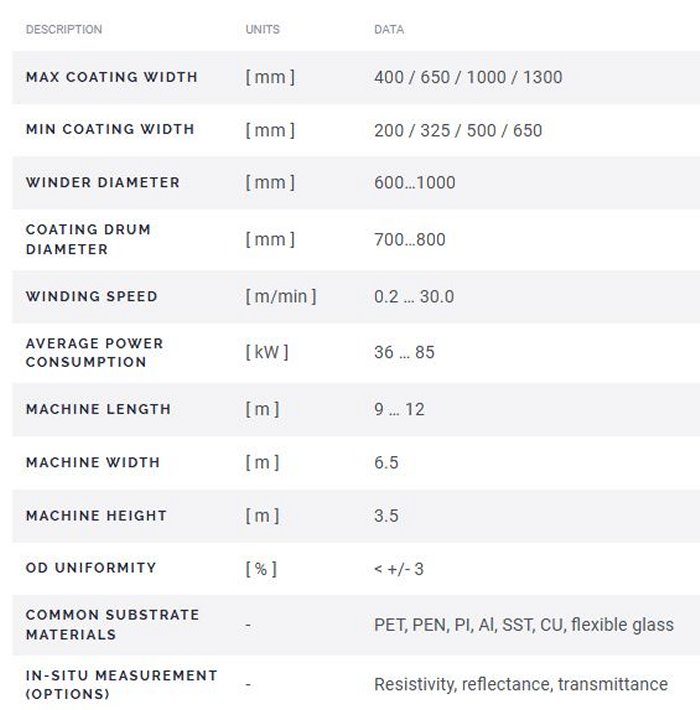

The NOVAWEB is an advanced high vacuum roll-to-roll coating platform by HS-GROUP, designed to meet current and future market demands for both production and R&D purposes. It has the capacity to house up to twelve rotatable magnetrons, providing exceptional productivity in manufacturing and the versatility needed for research and development. This platform is ideal for applications such as ITO films, flexible printed circuit boards, low-e coatings, and smart glass. The NOVAWEB's design includes optional gas separation capabilities between process sections, allowing for the deposition of complex layer combinations in a single pass. It can handle both reactive and non-reactive sputtering processes and can be equipped with various in-situ sensors to continuously monitor critical physical layer attributes such as resistivity, reflectance, and transmittance. This ensures enhanced control and optimization of the coating process, making it a comprehensive solution for flexible web coating needs.

HS-GOUP‘s innovative high vacuum roll-to-roll coating platform, known as NOVAWEB, effectively bridges the gap between productivity and adaptability, addressing the demands of both present and future markets.

The NOVAWEB stands as an ideal choice for both production and research and development (R&D) endeavors. Its remarkable potential lies in its ability to house up to twelve rotatable magnetrons and incorporate a wide range of in-situ measurement sensors. This unique configuration grants the machine exceptional productivity within manufacturing contexts while maintaining remarkable flexibility and versatility when employed for R&D purposes. This versatility positions the NOVAWEB as the primary option for applications like ITO films, flexible printed circuit boards (FPCB), low-e coatings, and smart glass.

Anchored by the proprietary rotatable magnetrons, the machine serves as a solid foundation for achieving high levels of productivity.

Furthermore, the NOVAWEB’s optional gas separation capability between adjacent process sections facilitates the deposition of an extensive array of conceivable layer combination involving metals and dielectrics in a single pass. Beyond its capacity to execute both reactive and non-reactive sputter processes, the NOVAWEB can be equipped with diverse in-situ sensors. These sensors enable continuous and precise monitoring of desired physical layer attributes such as resistivity, reflectance, and transmittance, enhancing the overall control and optimization of the coating process.