Flowdirect UK Ltd

- Home

- Companies

- Flowdirect UK Ltd

- Products

- Flowdirect - Offshore Submersible Pump

Flowdirect - Offshore Submersible Pump

Flowdirect UK Ltd`s philosophy is one of ultra-reliability and outstanding service. Using our 100 years of pumping experience and the latest computational techniques, the team at Flowdirect UK Ltd have engineered a submersible pump-set to suit the most arduous conditions.

Most popular related searches

submersible pump

non-return valve

submersible pump set

avoid water hammer

water drilling

ballast water

cooling water

drilling water

digital temperature controller

sanitary water

Pump

- Sizes: 4" - 12" bowls

- Max Capacities: 573m3/hr (higher flows available on request)

- Max Static Flow Temp: 55°C

- Max Head: 400m

- Speeds: 50Hz and 60Hz available

- Continuously rising head curves.

- Non-overloading power curves.

- Suitable for horizontal or vertical installation.

- Non-return valves available to prevent reverse rotation.

Motor

- Specially designed for offshore applications.

- Filled with Glycol/water.

- Sized for 120% of maximum pump power.

- Re-windable PE2 motor.

- Robust bearing construction to absorb hydraulic thrust loads and provide rotor dynamic stability.

Construction

- Ni-Al Bronze available as standard for hydraulic components.

- Duplex and Super Duplex available when requested.

Typical Applications

- Pre-fill water

- Mud mixing water

- Ballast water

- Drill water

- Wash down water

- Water curtains

- Cooling water

- Fire water

- Portable and sanitary water

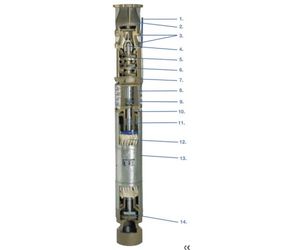

- Power supply cable: Flowdirect hold popular cable sizes in stock.

- Non-return valve: Spring loaded or gravity, non-clogging and canting. Short closing time avoids water hammer.

- Threaded Stud connections: Rapid and low cost dismantling with stainless steel studded connections.

- Bearing: water resistant bearings. High resistance against sand and vibration.

- Impellers: Wear resistant impellers of high quality bronze or stainless steel. Exact pump duties can be achieved through hydraulic modifications.

- Stationary and rotating wear rings: Wear resistant, replaceable stationary and rotating rings.

- Pump Casing: Materials available for all applications.

- Engineered coupling: Simple connection between pump and motor.

- Mechanical shaft seal and double lip seal system: highly wear resistant seal for a long life and integrity.

- Pump and motor shaft: High grade stainless steel of robust construction.

- Bearing sleeve: Double bearing sleeve made of synthetic carbon with spiral groove for cooling and lubrication of the motor.

- Motor cooling: Motor sized for pump max power. Option of temperature control in the motor by internal cooling circuit.

- Motor shroud: stainless steel.

- Counter axial thrust bearing: Resists axial up-thrust.