- Home

- Companies

- Calgon Carbon Corporation

- Products

- Fluepac - Model A - Powdered ...

Fluepac - Model A -Powdered Reactivated Carbon

FLUEPAC-A is a powdered reactivated carbon produced from bituminous coal specifically for use in flue gas treatment applications. FLUEPAC-A has a high effective surface area and a large pore volume making it very effective in removing many flue gas contaminants.

- Large number of high energy adsorption pores

- High effective surface area

- Good transport pore structure

- Completely devolatilized bituminous coal-based material

- High adsorption capacity for many pollutants.

- Effluent mercury levels of 0.5 µg/Nm3 and dioxin levels of 0.01 µg/Nm3 can be achieved.

- Ideal when VOCs are also a problem.

- Rapid adsorption kinetics lead to low required contact times.

- Product has a high ignition temperature which permits use over a wide temperature range. Safe bulk storage.

Added Benefits

Existing combustion or incineration systems can be quickly and inexpensively retrofitted to permit the addition of FLUEPAC-A powdered reactivated carbon. Operation is simple, reliable, and cost-effective. Utility requirements are low.

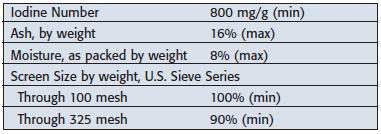

Powdered Activated Carbon (PAC) injection is currently recognized as the Best Available Control Technology (BACT) by the EPA for mercury removal in flue gas. FLUEPAC-A is ideally suited for the removal of mercury, dioxins, furans, and other VOC compounds from flue gas. FLUEPAC-A is easily captured with the fly ash via the use of existing particulate matter removal equipment and can typically be landfilled with the ash as non-hazardous. Although removal efficiencies depend on contaminant concentration, temperature, and available contact time, mercury levels in treated flue gas of 0.5 µg/Nm3 have been demonstrated. Since FLUEPAC-A is a completely devolatilized bituminous coal-based product, its use results in consistent low-level flue gas emissions over a wide temperature range. FLUEPAC-A also has a high effective surface area (l2 no. over 750) which makes it particularly effective for the renewal of VOCs. Typical bulk density is 25-30 Ib./ft3.

Some typical mercury, dioxin, and VOC control applications for FLUEPAC-A include:

- Municipal waste combustors

- Hazardous waste combustors

- Hospital waste incinerators

- Coal-fired power plants

- Cement kilns

- Industrial boilers