Series 971 - Model 971 Series -Fluid-Applied Acrylic Insulation Coating

An innovative, fluid-applied, thermal insulating coating utilizing aerogel particles that imparts exceptional insulative properties to a variety of substrates. Ideal for insulating pipes, valves, tanks, structural steel, or other substrates where thermal improvement or personnel protection is desired. Part of a durable, corrosion-resistant coating system that bonds to the substrate, greatly reducing the issues associated with corrosion under insulation (CUI) and mitigating thermal bridging by controlling condensation.

Special Qualifications

Thermal Conductivity (ASTM C518 at 77°F): 0.0356 W/m-°K or 0.2468 BTU-in/ft²-hr-°F (R value at one inch equals 4.1)

Flame Spread (ASTM E84): Class A

Smoke Developed (ASTM E84): Class A

Tested in accordance with NORSOK M-501/ISO 20340

Series 971 was tested in accordance with, and passed, the California Department of Public Health CDPH/EHLB/Standard

Method Version 1.1, 2010 emissions testing and meets qualifications of LEED v4, Collaborative for High Performance

Schools, and Living Building Challenge.

0 lb/gal solids

Steel: Series 90E-92, 90-97, 90G-1K97, 90-98, 91-H_2_O, 94-H_2_O, 115, 394, 1224. Note: The use of zinc-rich primers is not generally recommended when in-service temperatures exceed 120°F (49°C). Reference NACE SP0198 for more information.

Galvanized Steel and Non-Ferrous Metal: Series 115, 1224

Concrete: Series 1224

CMU: Series 1224

Note: Refer to appropriate primer data sheet for maximum temperature resistance.

Matte

1,219 mil sq ft/gal (30.0 m²/L at 25 microns). See APPLICATION for coverage rates. †

76 ± 2.0% (mixed) †

30.0 to 50.0 mils (762 to 1270 microns) per coat. Note: For use as a thermal break, recommended total dry film thickness is 80 to 100 mils (2032 to 2540 microns). Thickness may vary by project. Note: Multiple coats may be required, please contact your Tnemec Representative for film thickness recommendations.

0.016 lb/gallon (1.9 grams/litre) †

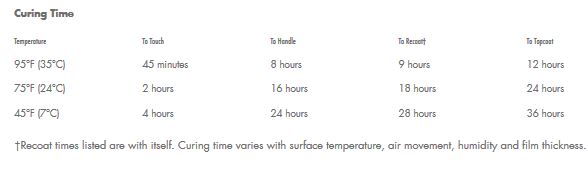

Series 22, 27WB, 72T, 115, 1028T, 1224. Other topcoats may be available, contact your Tnemec representative for more information. Note: A cure time of 24 hours at 75°F (24°C) is required before topcoating Series 971. Extended cure time may be required at lower temperatures.

Number of Components

One