- Home

- Companies

- Henan Fote Heavy Machinery Co., Ltd.

- Products

- Fote - Impact Crusher

Fote - Impact Crusher

The impact crusher has features of simple structure, small volume, light, high production, low production cost, big feed port, deep crushing cavity and being suitable for materials with good hardness.

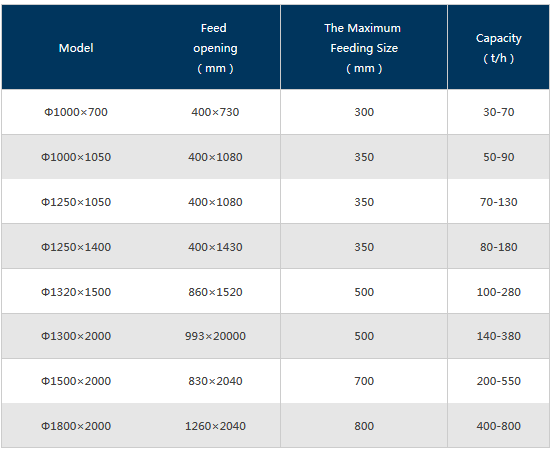

- Processing capacity: 30-800 t/h

- Feeding size: 300-700 mm

Applied materials : stone, rocks, pebble, limestone, granite, quartz, concrete, basalt and other minerals.

Advantages of Impact Crusher:

- The minerals are crushed along the joint surface, thus realizing low power consumption and high efficiency.

Why Choose Us?

- 1. Big crushing ratio, cubic particles of finished product.

- 2. No tension and cracks.

- 3. Long lifespan of wearing parts.

- 4. Cheaper than cone crusher, big capacity, better particle size, uniform appearance.

- The impact crusher has a high crushing ratio of 40, thus simplifying the crushing process from the three periods crushing to two or one period crushing, which saves the equipment fee of the dressing plant.

- It`s simple to adjust the space between the impact plate and the plate hammer, so material size is easy to control and with good particle shape.

- The chromium plate hammer is featured in shock resistance, abrasion resistance and great impacting force.

- The whole impact crusher has realized seamless connection which makes it easy to maintain and economical and durable to apply.

- The impact crusher has complete function and high production. It produces little machine parts abrasion and high overall efficiency.

Stone materials fall from the upper end of the impact crusher directly into the high-speed revolution rotary table. Under the high speed centrifugal action, these materials have high velocity impact with those flying stones at high speed spreading all around the turntable in an umbrella shape and get crushed in high density.

When the materials impact with each other, they will move in eddy current between the turntable and the main case of the impact crusher and then they have multiple striking, rubbing and crushing until they are discharged from the bottom tank. The impact crusher adopts closed circuit manifold cycles and makes sure the particle size of the materials is controlled by the screening equipment.