BSI - Model DATS-IV -Fouling Monitoring System

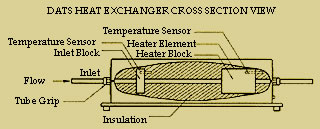

The DATS-IV Fouling Monitor utilizes the latest in microprocessor technology to simulate condenser / heat exchanger environment on a fluid side stream through a controlled tube section. By matching the tube material, heat flux, and flow rates to an actual process, the DATS-IV is able to provide vital information regarding performance degradation, and economic loss due to fouling. Calibrated temperature probes within the DATS heat exchanger accurately measure both fluid and heater temperatures, and is used along with power input to calculate the heat transfer. All heat transfer data is then provided as analog output signals to tie in with customer equipment.

- Heat Flux Wall Temperature

- Fluid Velocity

- Fluid Temperature

- Block Temperature

- Heat Transfer Resistance

RS-232 and analog communications interfaces

Analog Outputs Proportional To:

- Water Temperature: [32 - 280 °F]

- Block Temperature: [32 - 280 °F]

- Wall Temperature: [32 - 280 °F]

- Flow Velocity: [ 0 - 13 ft/sec]

- Heater Power: [0 -4,778 BTU/Hr]

- Heat Transfer: [-5.4-4 to 2.271-2 Resistance Hr-°F-ft2/BTU]

Analog Control For:

- Heater Power: [0 -4,778 BTU/Hr]

- Flow Velocity: [ 0 - 13 ft/sec]

- AC Power: 120 or 240 VAC, 50/60 Hz Maximum

- Heat Flux: 50,000 BTU/hr•ft2

- Maximum Fluid Temperature: 180 °F Flow velocity Range: 0.5 to 10 ft/sec.

- Tube Specifications: Any commercially available alloy

- Outside Diameter: 14mm; 5/8" to 1"

- Wall thickness: 0.028" to 0.134"

- Environmental Resistance: Plastic sealed enclosure, stainless steel and aluminum exterior

- Wetted Components: CPVC, EDPM diaphragm PVDF paddlewheel, Titanium pin, tube material