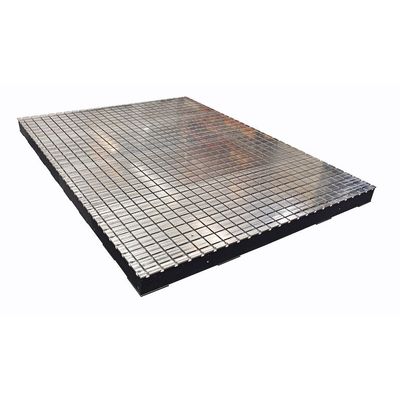

Framag HYDROPOL - Clamping Plates

Vibration damping at the highest level, from 6 weeks delivery time, optimized vibration-damping approx. 50% CO2 savings in production, 100% recyclable, electrical potential equalization.

The composite material developed by framag offers clear advantages to numerous customers worldwide in mechanical engineering and test bench technology. Hydropol offers 7 times higher vibration damping than steel at very high strength. This minimizes tool wear, noise emission & maintenance effort and significantly increases precision.

- Non-shrink & dimensionally stable mineral filler

- various fillers with specific weights and E-modules

- completely individual solutions made to measure

- processing of components up to 60t and 12m length

- tuning based on finite element simulation

- empty tubes, openings and pipes possible

- lifting & fastening threads possible

Maximum individuality & performance

In engineering as well as in production the focus is on the requirements of the customer. framag offers highest model flexibility due to composite design and develops clamping elements in such a way that the requirements of the customer are fulfilled 100%.

- technical advantage of HYDROPOL® technology

- Fast solution for short-term requirements

- standard components, based on modular design principle

- short lead time (delivery within 6 weeks incl. mechanical processing)

- Longitudinal / cross grooves in the range 10H12 - 28H12

- Freely selectable groove spacing

Standardized, but better than standard.

The ECOPOL clamping elements offer the technical advantages of Hydropol in the form of a standardized product line of clamping plates, angles and cubes. The components consist of a modular design and convince with fast delivery time, low costs and clear ecological advantages.

- 50% CO2 savings in production compared to conventional cast components

- ECOPOL® clamping elements are 100% recyclable

- No epoxy or polyester resins in the filler material

- No toxic gases when exposed to heat