- Home

- Companies

- Franklin Miller Inc.

- Products

- Franklin Miller Taskmaster - Model ...

Franklin Miller Taskmaster - Model TM8500 -Wastewater Grinder

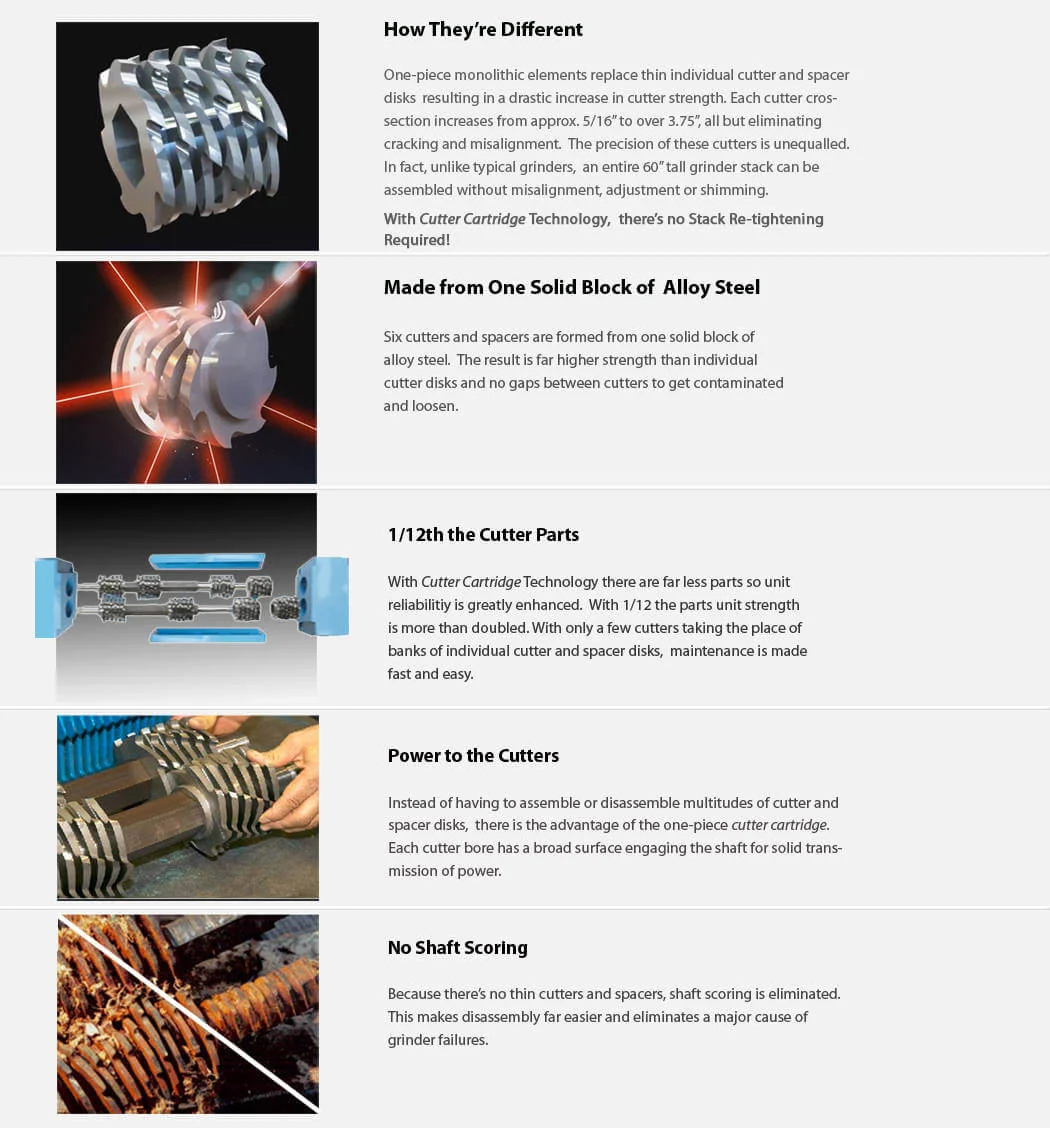

The TASKMASTER TM8500 Wastewater Grinder is engineered to deliver effective reduction of wastewater solids with its innovative twin shaft design and dependable mechanical seals. It utilizes CUTTER CARTRIDGE Technology for finely reducing solids like rags, plastics, wipes, paper, and more, mitigating common issues such as pump ragging and downstream equipment clogging. These grinders are ideal for applications in sewage, sludge, septage, and screenings across various installation settings, including open channel and inline configurations. Crafted for robust performance, the unit ensures minimal vibration and operates quietly. Its construction is optimized to protect against premature filter press media failure, particularly when dealing with challenging solids, thereby minimizing downtime and enhancing system reliability.

The TASKMASTER® TM8500 twin shaft grinders provide unsurpassed grinding of wastewater solids, and design features that make them truly unique. These units have proven their capability and unique reliability in installations worldwide. TASKMASTER grinders feature dependable mechanical seals in a cartridge design and CUTTER CARTRIDGE® Technology.

These grinders reduce pump ragging and problems with downstream equipment by finely reducing such solids as rags, plastics, wipes, paper, disposables, fabrics, wood, bottles and much more. They are built for sewage, sludge, septage and screenings applications in either open channel, inline or gravity installations. Each unit is heavily constructed for low vibration and quiet operation.

- CUTTER CARTRIDGE® Technology

- Coarse or Finely Cut Output Configurations

- Few Moving Parts

- No Stack Retightening

- Rugged Construction

The TASKMASTER, installed inline, significantly reduces pump downtime, ragging from stringy solids and sanitary wipes, as well as offers protection from premature filter press media failure.

These grinders reduce pump ragging and problems with downstream equipment by finely reducing such solids as rags, plastics, wipes, paper, disposables, fabrics, wood, bottles and much more. They are built for sewage, sludge, septage and screenings applications in either open channel, inline or gravity installations. Each unit is heavily constructed for low vibration and quiet operation.

- CUTTER CARTRIDGE® Technology

- Coarse or Finely Cut Output Configurations

- Few Moving Parts

- No Stack Retightening

- Rugged Construction

- Wet Well Frame

- Pre-engineered FRP Manhole

- Hydraulic Drive

- Stainless Steel