Kingfisher - Model K-ZAS -Fused Corundum Lining System

K-ZAS is rated at 9 MOHS and is ideally suited to the protection of plant suffering from severe abrasion and erosion. The material also has a high resistance to thermal shock. The raw materials used for the manufacture of our K-ZAS lining material are zirconia, alumina and silicon which are crushed, screened and fed into an electric arc furnace where it is smelted at 1450°C. At this stage the minerals are converted into a molten state and cast into moulds. These components remain in the moulds and are placed into an annealing chamber where dependant on the volume of the casting determines what duration of heat treatment is required, where at the end of this process results in a material with characteristics of extreme abrasion resistance as well as resistance to high thermal stresses.

Application

The primary use of our K-ZAS material is for the protection of plant and equipment encountering severe abrasion and erosion attack from bulk solids being conveyed, stored or processed by mechanical, pneumatic or hydraulic means. Rated nine on the MOHS hardness scale and having excellent thermal shock resistance, K-ZAS is ideally suited to counter excessive abrasion and high temperatures for applications within the bulk solids handling and mineral processing industries.

Forms of supply

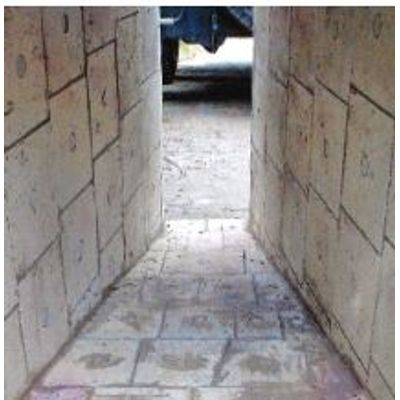

Many different forms can be produced in thickness ranging from 25mm to 500mm. These can take the form of flat or radiused tiles, cylinders, cast straight or on a true arc and special shapes manufactured to line complex fabrications where the use of standard forms would comprise the geometry of the substrate.

Installation

The majority of installations are carried out using a range of adhesives with differing characteristics depending on the application. Where adhesives are either not suitable to use or the curing time is not fast enough to support the weight of the component in either a vertical or inverted position then mechanical fixings can be used. Kingfisher Industrial can supply a full range of adhesives and mechanical fixings dependant upon the applications.

As with most wear resistant materials the success of the systems often depends on the quality and accuracy of the installation. We recommend consultation takes place with one of our qualified engineers in order to assess the suitability of choosing our K-ZAS material for particular applications. If need be Kingfisher can carry out the installation using its own fully trained work force or supervise your own employees.

- Extreme abrasion resistance

- Good thermal shock

- characteristics

- Manufacture of large components

- Constant operation at elevated temperatures