- Home

- Companies

- Hebei Zhaoyang Environmental Technology ...

- Products

- Zhaoyang Tank - Fusion Bonded Epoxy ...

Zhaoyang Tank - Fusion Bonded Epoxy Coated Steel Bolted Tank

Fusion Bonded Epoxy (FBE) Steel tank is a steel tank coated with an epoxy resin layer, which is applied through a process called fusion bonding. This involves heating the resin until it melts and merges with the steel surface, creating a protective coating. These tanks are widely utilized for applications such as drinking water storage, fire fighting, irrigation, rainwater harvesting, and industrial water storage. They can store bulk solids and be used as filter tanks or for municipal sludge storage and treatment. The tanks come in multiple sizes, from small residential to large industrial sizes, and can be customized to specific requirements. FBE tanks provide cost-effective protection, but they may require more maintenance in highly corrosive environments compared to glass-coated steel tanks. Each panel's contact surface is thoroughly tested before dispatch. The epoxy coating lends excellent corrosion resistance, longevity, aesthetic appeal with a smooth surface, and easy maintenance. ZHAOYANG leverages advanced technology, including CNC punching machines and laser cutting equipment, for manufacturing these durable and corrosion-resistant tanks, making them suitable for diverse applications.Fusion Bonded Epoxy (FBE) Steel tank is a type of tank that is coated with a layer of epoxy resin. The epoxy coating is applied to the steel surface through a process called fusion bonding, which involves heating the resin until it melts and fuses to the steel surface.

Fusion Bonded Epoxy (FBE) Steel tank is a type of tank that is coated with a layer of epoxy resin. The epoxy coating is applied to the steel surface through a process called fusion bonding, which involves heating the resin until it melts and fuses to the steel surface.

FBE Steel tanks are commonly used for various applications, including drinking water storage, fire fighting, irrigation, rainwater harvesting, and industrial water storage, bulk solid storage, potable water, filter tanks and municipal sludge storage.They are available in a variety of sizes, ranging from small residential tanks to large industrial-sized tanks, and can be customized to meet specific needs and requirements. It is a low-cost solution that delivers good protection.

However, in some applications with highly corrosive environments or where abrasive contents are present, a reduced service life and a potential requirement for increased maintenance may be required when compared to a glass contact surface finish such as GFS tank.

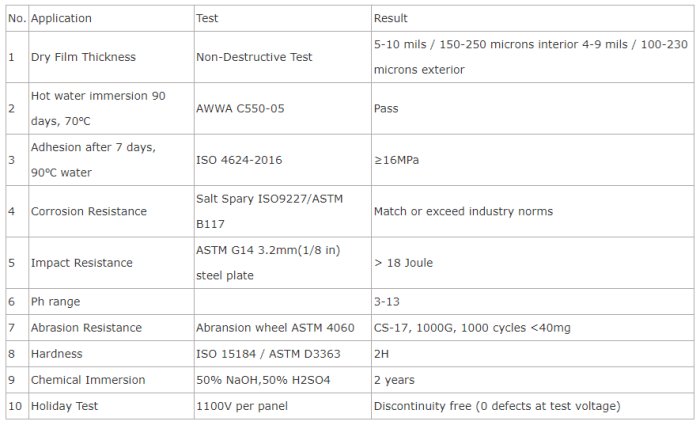

The contact surface of every panel supplied is 100% factory tested and inspected.

Edible/Vegetable Oils

Dry Bulk Solids

Farm Digesters (Liquid Zone)

Fire Water

Potable Water

Filter Tanks

Municipal Sludge Storage (Open Topped)

Municipal Sludge Treatment (Open Topped)

All applications are subject to chemical concentration and temperature considerations. All specifications relate to the contact surfaces only. A detailed specification is available on request.