- Home

- Companies

- Zhengzhou Fusmar Machinery Co., Ltd

- Products

- Fusmar - Model PLM - Electric Flat Die ...

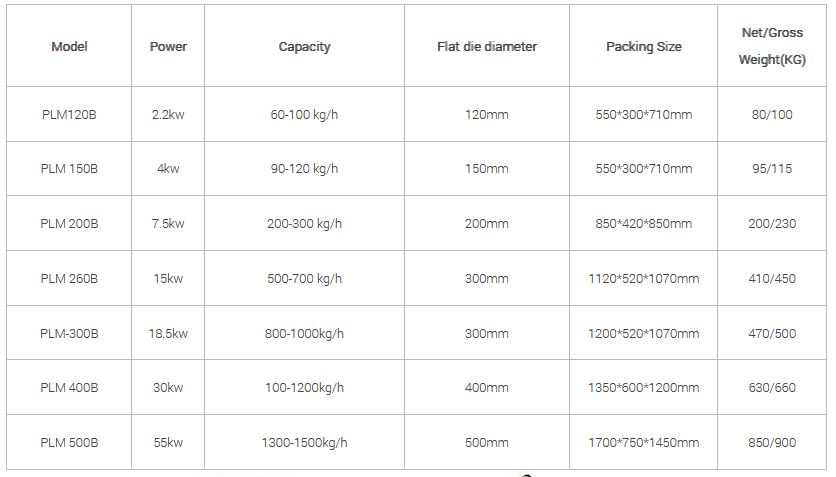

Fusmar - Model PLM -Electric Flat Die Pellet Machine

The pellet animal feed market is growting fast with recent years, the falt die feed pellet machines are welcome in the breeding industry. The animal feed pellet market is growing fast with recent years, the flat die feed pellet machines are welcome in the breeding industry. The flat die feed pellet machine has the advantages of simple structure, covering a small areas, low cost, and low consumption. That’s why more and more plants and families are choosing them to produce the feed pellets.

Raw Materials For Animal Feed Pellets Making

Raw materials include corn, maize, alfalfa, wheat bran, grass, rice, beans, oil cake, etc. If the size of the materials is larger than 6mm, the materials should be ground by the hammer mill. Usually, protein or other nutrients can also be added to the powdery raw materials.

- The Feeding Way. Flat die pellet machine feeds the material into the pressing chamber vertically by the weight of itself. And the processing speed is even.

- The diameter of the roller is out of the limit of the flat die, it can expand the inner bearing space. The bigger bearing not only can increase the endurance of the roller but also improve the pressing power and prolong its life-span.

- The Discharging Way, the flat die has low rotation speed, then its low rate of spoiled pellets.

- The roller way adjusting way. Flat die roller can adjust with the thread column by manual rotation or hydraulic automation.

The first pellet mill design at the turn of the 20th century based on flat dies. Generally, there are two types of flat die pellet mills in the market, the rotating die type, and the rotating roller type. The former has a stationary roller with the rotating die while the latter has a stationary die with a rotating roller. Adopting vertical principle, the raw materials drop down by its own weight into the pelletizing chamber where they are compressed between the rollers and die to form pellets by going through the die holes.