- Home

- Companies

- Walle Industry

- Products

- Walle - Gantry Hydraulic Shear

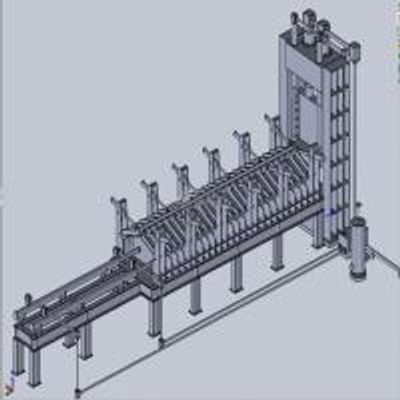

Walle - Gantry Hydraulic Shear

Gantry shear is used for shearing various metal plates. It is an ideal equipment for charge treatment in rolling mills, non-ferrous metal plants and smelters.

Equipment suitable for heavy-duty scrap cutting processing, which is used for cold cutting of various scrap metals such as light and thin steel, reinforcement, steel plate, nickel plate, steel plate, round steel, steel pipe, scrap copper, scrap steel, scrap iron, light metal structural parts, stainless steel, metal pressing block, automobile body, aluminum alloy, copper, scrap iron, steel wire, metal pressing block, etc., and processing them into qualified furnace charge. It can be used not only as processing equipment for metal recycling and processing units, but also as furnace charge processing in factory casting workshop and metal cutting processing equipment in mechanical construction industry.

- The gantry shear adopts hydraulic transmission. Compared with the mechanical transmission shear, it has the advantages of small volume, light weight, small inertia, low sound, stable action, convenient and flexible operation, large shear section and convenient adjustment of scissors mouth. It is safe to operate and easy to realize overload protection.

- The gantry shear has manual, automatic and remote control functions, which is convenient and simple to operate and control. The shear port can start and stop at any position in the working process, and the size of the shear port can be controlled arbitrarily according to the size of the sheared material, so as to obtain economic working benefits.

- The gantry shear is designed with rapidity. Under the condition of not increasing the motor power and oil pump displacement, the speed remains fast under the shear (about 400-1600 tons), and the speed will be automatically changed when shearing large materials. Restore the original shear force, so as to nearly double the work efficiency.

- The gantry shear is equipped with a fast device. Without increasing the motor power and oil pump displacement, a fast circuit is designed to increase the shear speed from 8 times per minute to 12 times per minute (referring to the times when the scissors open their mouth), and the work efficiency is nearly doubled. This function is unique among peers in China.